Method for producing rhcg by high-efficiency fermentation of cho cells

A fermentation method and cell technology, which is applied in the field of protein and cell culture, can solve the problems of high production cost, long time consumption, and large influence of accidental factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Cells, culture medium and other reagents used in fermentation

[0019] The CHO cells used for the fermentation were made by the applicant, and the vector carrying the rhCGα and β subunits was transfected into the CHO cell K1 strain using LipofectamineTM2000 lipofection reagent. in pilot production for more than 18 months.

[0020] The medium prepared by the applicant for the fermentation process:

[0021] Passaging medium:

[0022] CD CHO AGT 24.3mg / ml, dihydrogen phosphate monohydrate 2.69mg / ml, disodium hydrogen phosphate 4.33mg / ml, L-arginine 550mg / ml, L-asparagine 1300mg / ml, L-aspartate Acid 400mg / ml;

[0023] Fermentation mixed medium:

[0024] CD CHO AGT 24.3mg / ml, CD OPTICHO AGT 9.66mg / ml, sodium dihydrogen phosphate monohydrate 2.69mg / ml, disodium hydrogen phosphate 4.33mg / ml, biotin 0.15mg / ml, folic acid 11.5mg / ml, muscle Alcohol 120mg / ml, potassium chloride 300mg / ml, glucose 5500mg / ml, sodium chloride 2100mg / ml, soybean hydrolyzed protein 30mg / m...

Embodiment 2

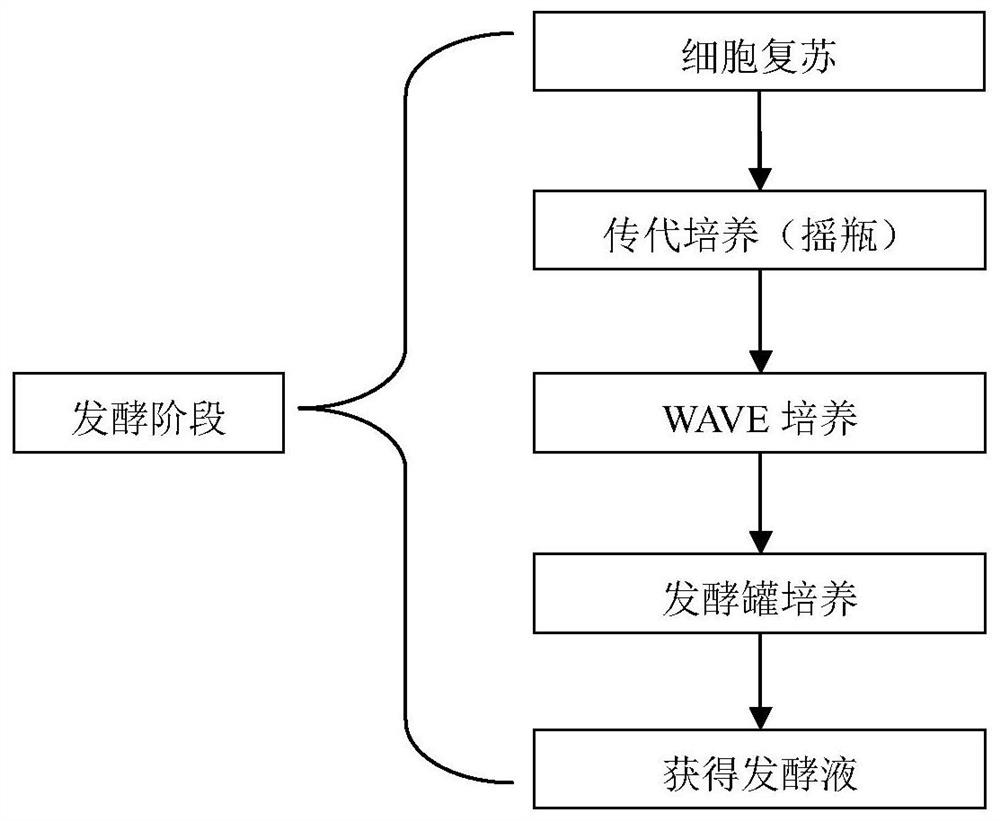

[0035] Example 2 Basic fermentation production process

[0036] Cell recovery:

[0037] 1) Take the cell cryopreservation tube and place it in a 37°C water bath until the frozen cell suspension is thawed.

[0038] 2) Transfer the cryopreserved cells to a centrifuge tube containing 6-7 ml of CHO subculture medium, centrifuge at 1000 rpm for 5 minutes, and remove the supernatant.

[0039] 3) Gently pipet the clumped cells at the bottom of the centrifuge tube with 10 ml of CHO subculture medium.

[0040] 4) Inoculate into a 125ml shake flask containing 10ml of CHO subculture medium, so that the final volume is about 20ml, and the inoculated cell density is 0.4-1.0*10 6 cells / ml. Place the shake flask in a carbon dioxide incubator at 36.5±1°C, 5±3% CO 2 , 125±10rpm to cultivate.

[0041] pass on:

[0042] 1) Shake flask culture: place the cell shake flask in a carbon dioxide incubator at 36.5±1°C, 5±3% CO 2 , 125±10rpm to cultivate. Perform cell counts every day, when the ...

Embodiment 3

[0047] Example 3 Optimization of fermentation process

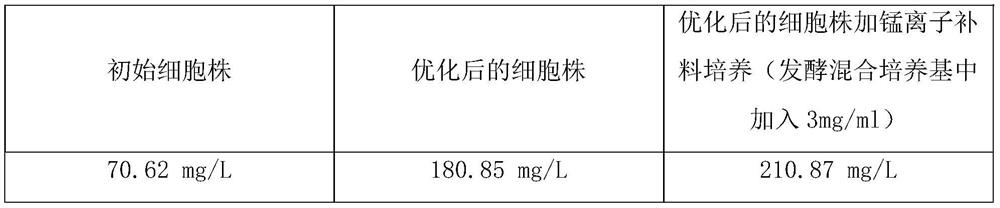

[0048]After the optimization of fermentation parameters and cells in the early stage, our method achieved an expression level of about 180 mg / L of recombinant protein within 12 days. In order to further increase yield / reduce cost at similar yields, we have made further improvements to the custom media ourselves. With reference to the prior art, try adding MnCl to the culture medium 2 (Add 3mg / ml to the fermentation mixed medium), hydrocortisone, sodium pyrophosphate, the results are as follows:

[0049] Table 1 The effect of adding manganese ions in the optimized cell line and fermentation mixed medium on the expression level (average of three-tank samples)

[0050]

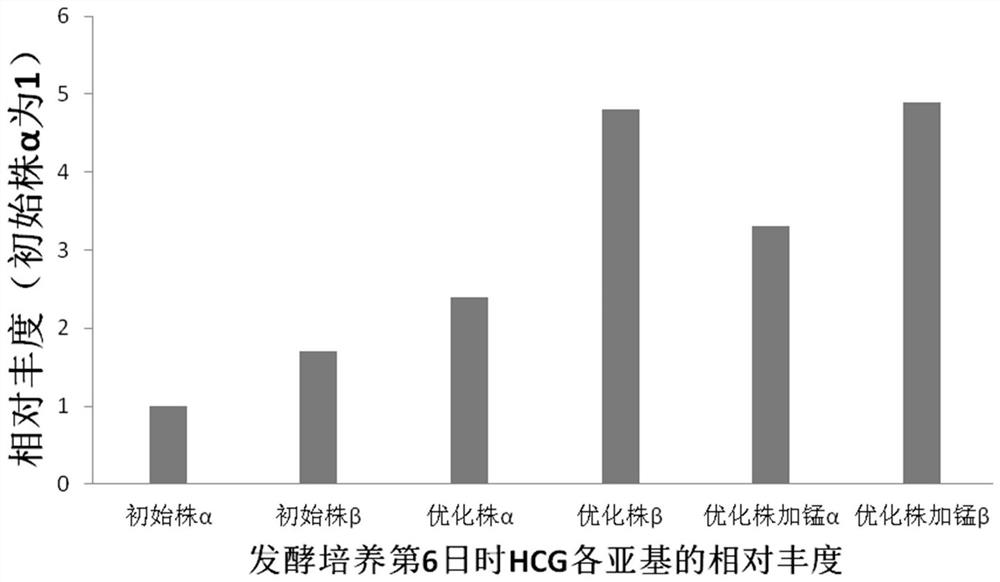

[0051] Further study of transcript level results such as figure 2 Shown: We found that the ratio of β-subunit to α-subunit in the optimized cell line was significantly higher than that in the initial cell line, which means that the transcriptional exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com