VOCs waste gas flow control method of fuzzy neural network PID based on heat balance feedback

A fuzzy neural network and heat balance technology, applied in the direction of flow control, flow control using electrical devices, non-electric variable control, etc., can solve problems such as temperature rise, inability to control flow, and treatment substandard, to minimize energy consumption , the effect of novel structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

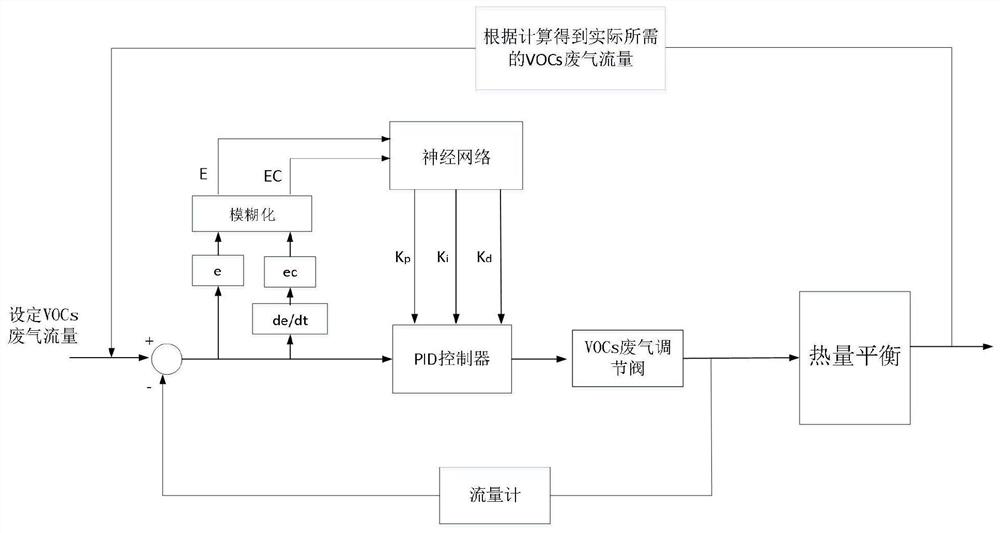

[0045] figure 1 It is a schematic diagram of the system structure of the fuzzy neural network PID control of the heat balance feedback of the present invention, by figure 1 It can be seen that the error between the VOCs exhaust gas flow set value and the actual output value and the error change rate are fuzzy quantified and sent to the neural network, and the intake volume of VOCs exhaust gas is adjusted through the fuzzy neural network PID controller; The required VOCs exhaust gas flow is fed back to the input in real time, and compared with the actual output value, it is transmitted to the neural network and continues to be adjusted.

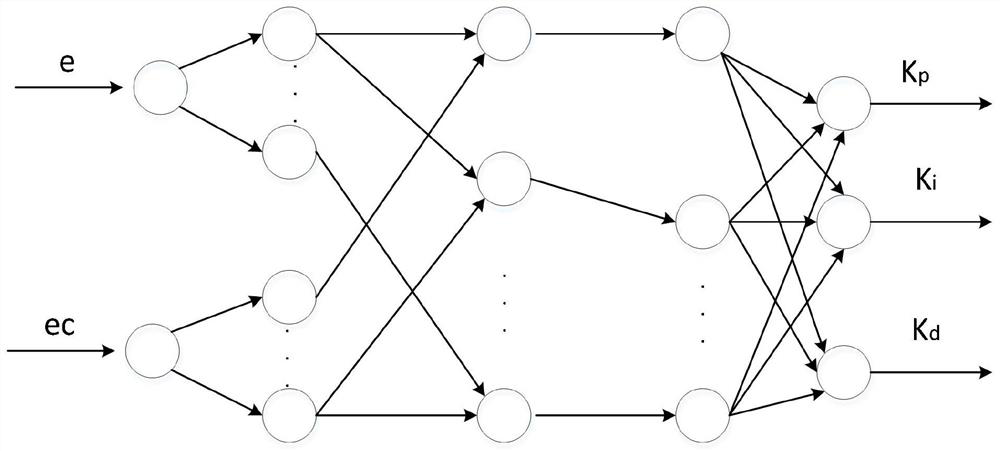

[0046] figure 2 For the fuzzy neural network structure diagram of the heat balance feedback that the present invention implements, by figure 2 It can be seen that the fuzzy neural network structure model consists of five...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap