Grabbing device for intelligent manufacturing of engineering equipment

A technology of intelligent manufacturing and grabbing devices, applied in the field of mechanical devices, can solve the problems of unsatisfactory practicability, inability to place, move or assemble parts, etc., and achieve the effect of strong practicability, precise position adjustment and excellent use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

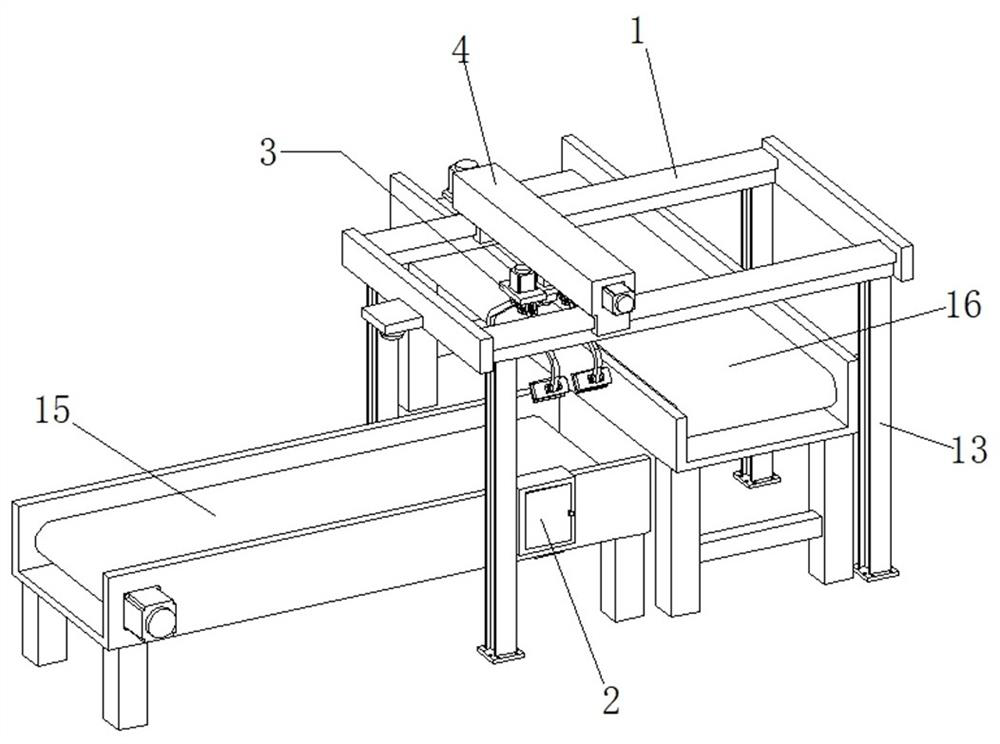

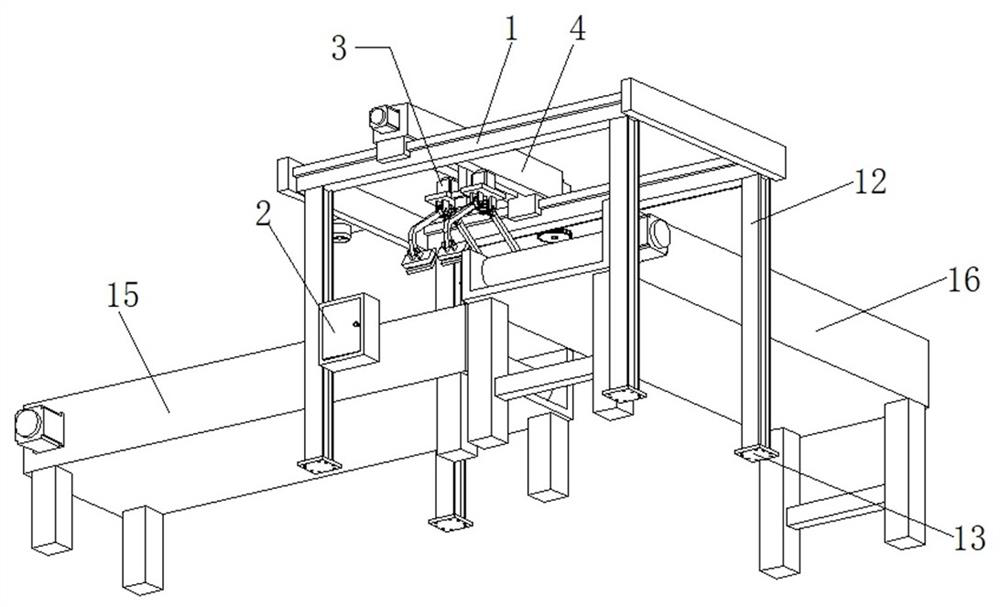

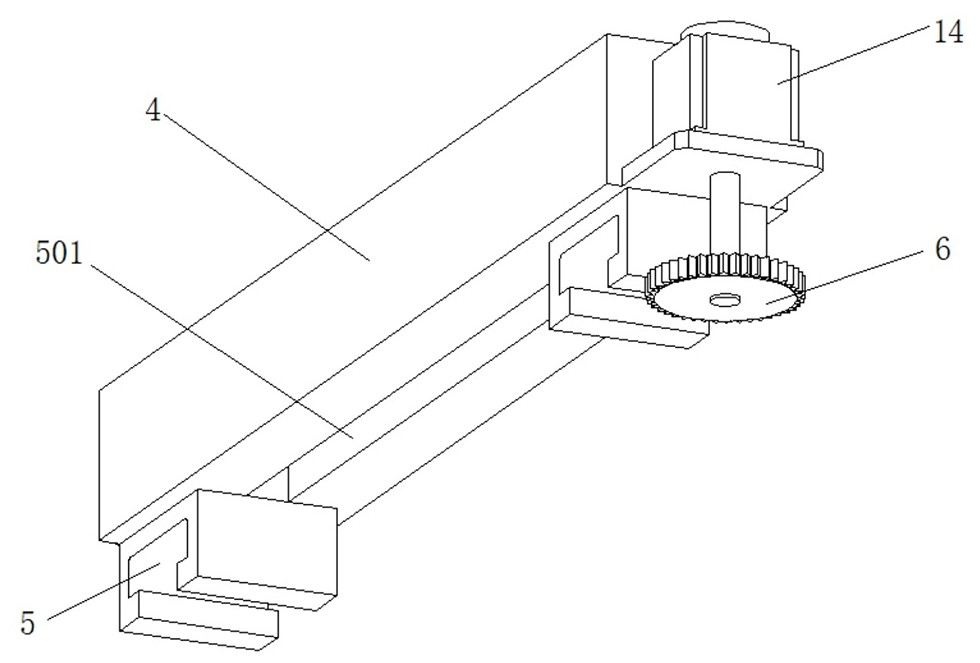

[0038]This embodiment 1 discloses a grabbing device for intelligent manufacturing of engineering equipment, refer to the attached figure 1 And attached figure 2 , its main components include horizontal rails 1, electrical cabinets 2, and grabbing mechanisms 3 arranged on both sides of the front and rear of a section of engineering equipment production line, columns 12 are connected to the left and right ends of each horizontal rail 1, and the lower ends of the columns 12 are connected to The base 13 is provided with a plurality of connection holes. During the installation process of the whole grabbing device, the expansion screws are inserted into the connecting holes, and then holes are opened on the ground to cooperate with the expansion screws, so that the fixed installation of the upright column 12 and the transverse rail 1 can be realized. Simultaneously, a first object conveyer belt 15 and a second object conveyer belt 16 are arranged directly below the transverse trac...

Embodiment 2

[0044] Embodiment 2 discloses an improved grasping device for intelligent manufacturing of engineering equipment based on Embodiment 1. Refer to the attached figure 1 And attached figure 2 , its main components include horizontal rails 1, electrical cabinets 2, and grabbing mechanisms 3 arranged on both sides of the front and rear of a section of engineering equipment production line, columns 12 are connected to the left and right ends of each horizontal rail 1, and the lower ends of the columns 12 are connected to The base 13 is provided with a plurality of connection holes. In the installation process of the whole grabbing device, the expansion screws are inserted into the connection holes, and then holes are opened on the ground to match the expansion screws, so that the fixed installation of the upright column 12 and the transverse rail 1 can be realized. At the same time, a first object conveyor belt 15 and a second object conveyor belt 16 are arranged directly below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com