A jacking type grout pouring operation device

A working device and jack-in technology, which is applied in construction, excavation, infrastructure engineering, etc., can solve the problems of difficulty in ensuring the uniformity of grouting on the pile side and difficulty in realizing separate construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

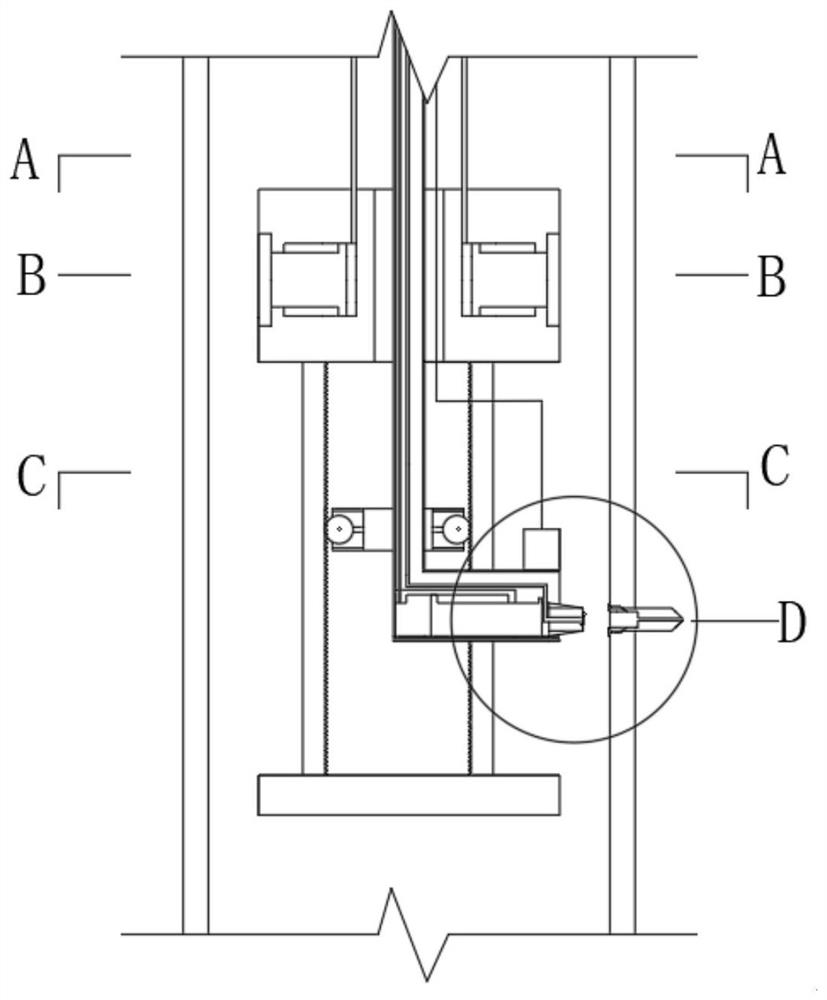

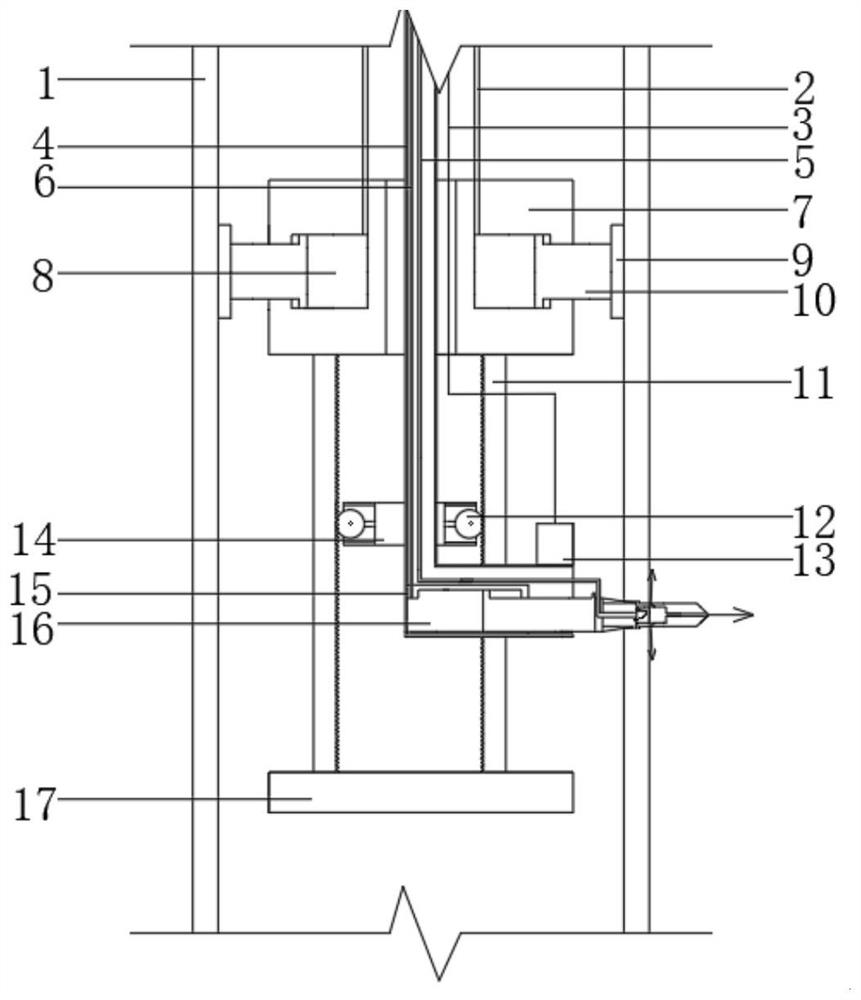

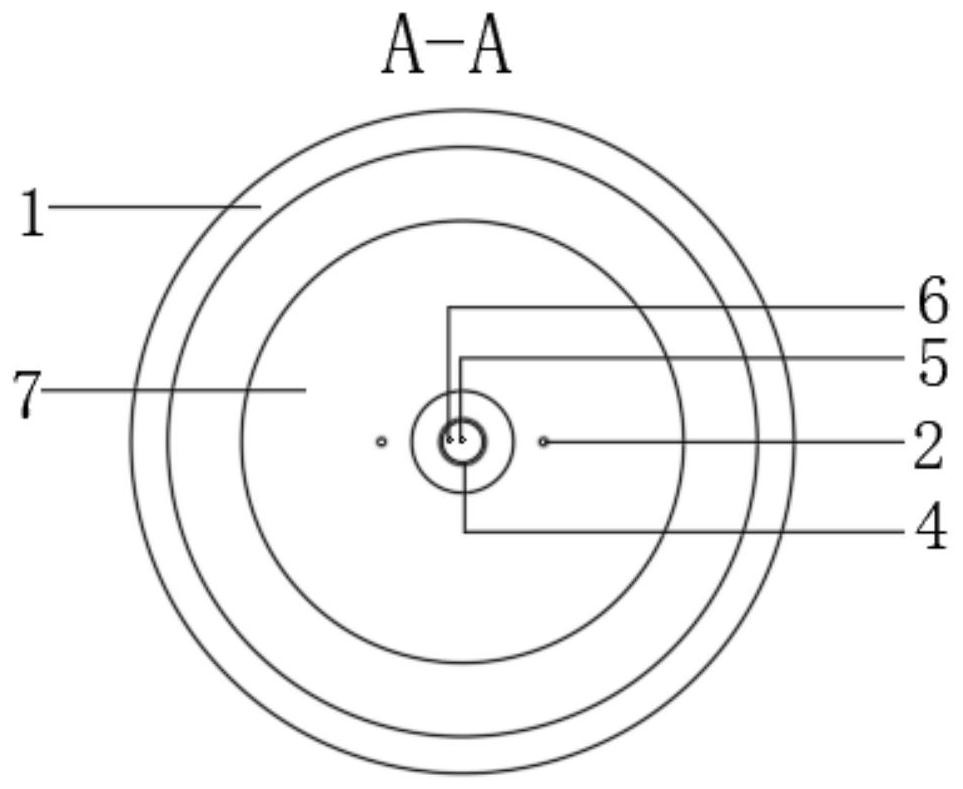

[0029] refer to Figure 1~2 As shown, a jacking type grouting operation device of this embodiment is built in the grouting pipe 1 as a whole, and the grouting operation is performed in the grouting pipe 1; the grouting operation device includes locking support parts, longitudinal positioning parts and Horizontal jacking parts; among them, the locking support part is used to provide a support platform fixed at a certain depth in the grouting pipe 1 for the pouring operation device; a vertical through hole is opened in the center of the top of the locking support part, and the central installation pipe 4 Through the through hole and can move vertically in the through hole, the top of the central installation pipe 4 protrudes from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com