Multi-station framework switching structure of injection machine

An exchange structure, multi-station technology, applied in the field of rubber injection, can solve the problems of low positioning accuracy of repeated docking, safety production accidents, damage to machine guide rails, etc., to avoid inaccurate alignment, safe and reliable use, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

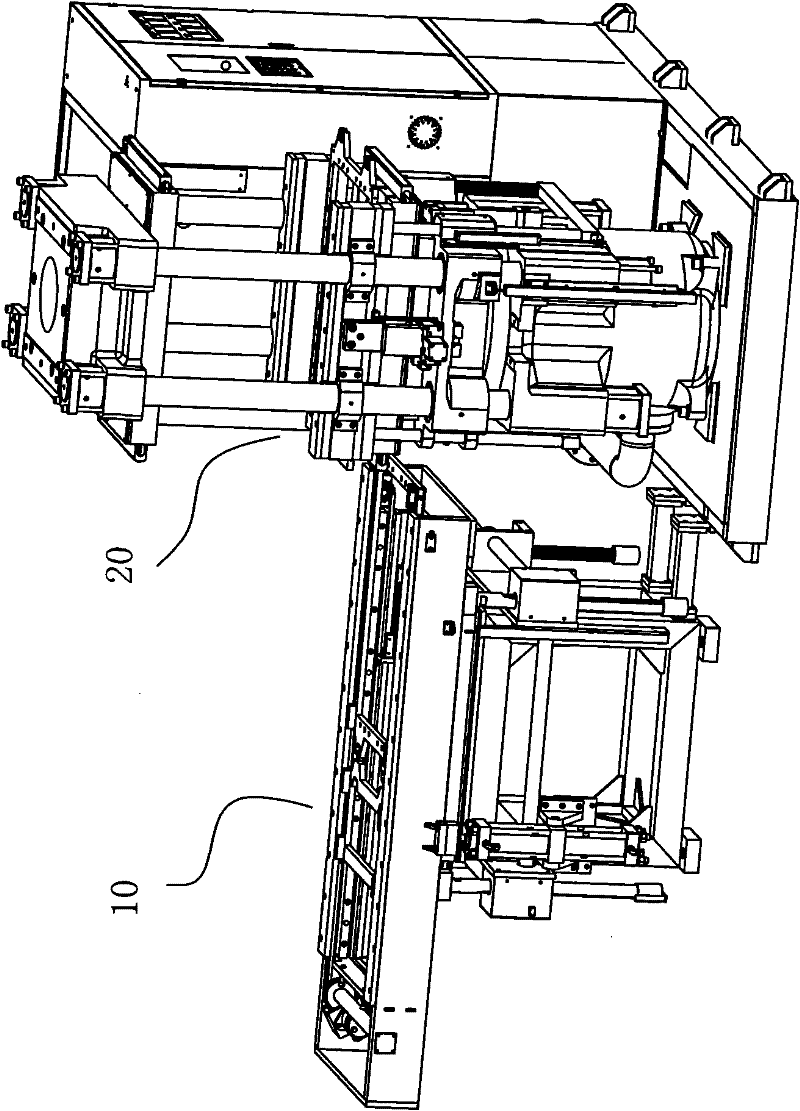

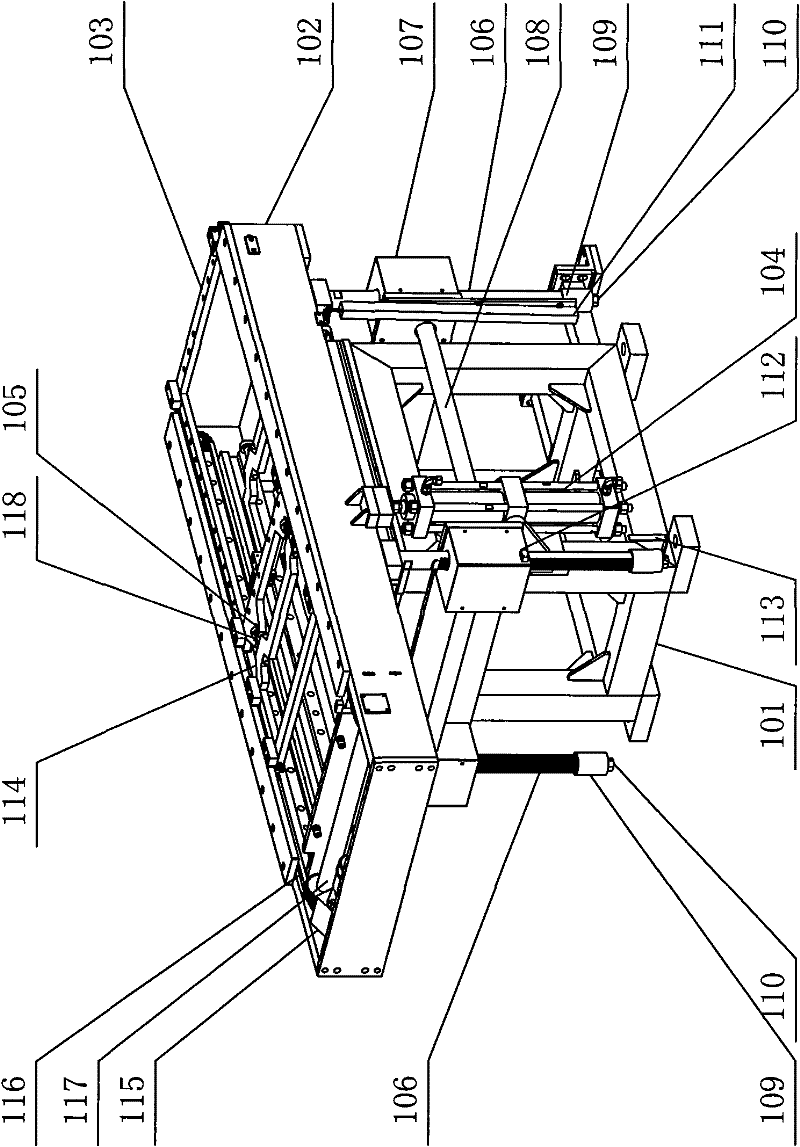

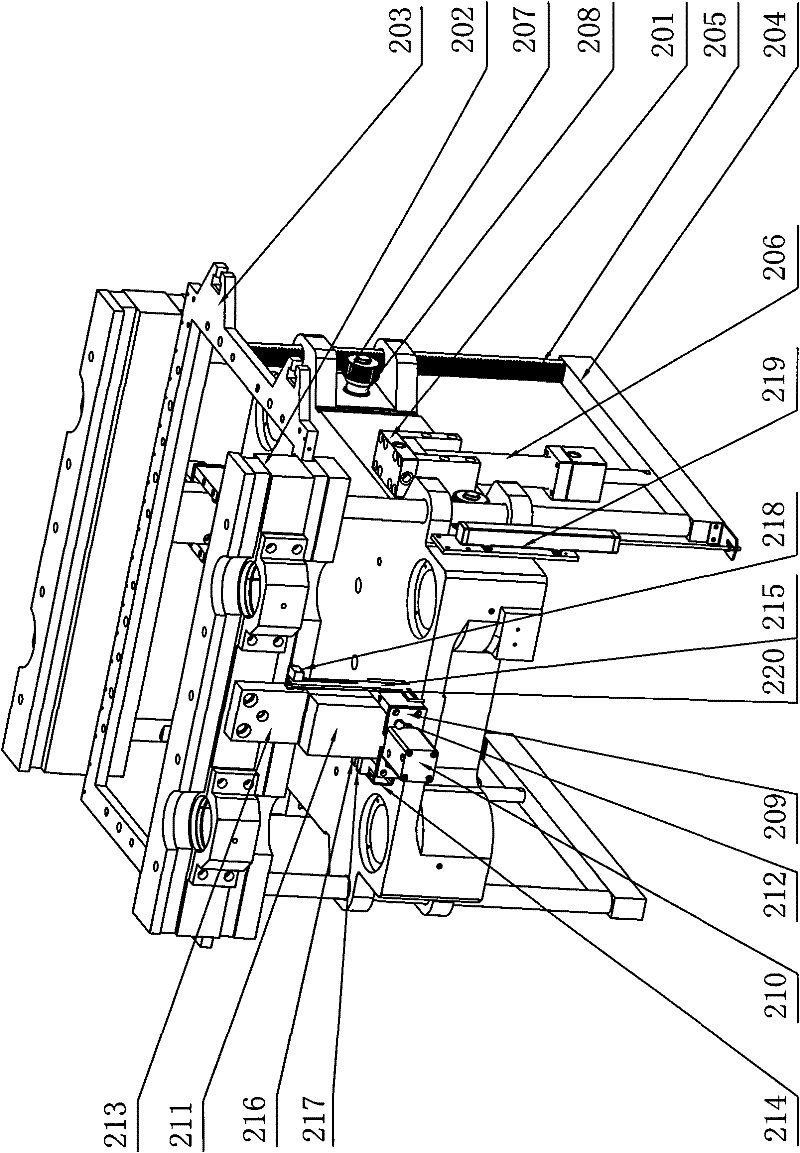

[0027] like Figure 1 ~ Figure 3 As shown, the injection machine multi-station template exchange structure of the present invention includes a mold moving assembly 10 for conveying and supporting a template frame 103 of the lower template (not shown in the figure) and the lower template (not shown in the figure) out) and the template frame 103 into the hanging mold assembly 20 for injection molding, the mold moving assembly 10 includes a mold moving support frame 101, a mold moving seat 102 placed on the mold moving support frame 101, for supporting The formwork frame 103 of the formwork is placed on the mold-moving base 102, on the formwork frame 103 is also connected with a carriage 114 for the multi-station horizontal movement of the lower formwork and the formwork frame 103, and the mold-moving support frame 101 is provided with a driveable The mold-moving base 102 lifting device that moves the mold-moving base 102 up and down, the template frame interchange device that ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com