Patents

Literature

30results about How to "Short exchange time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for rapid preparation of SiO2 aerogel micro-balloons

The utility model relates to a rapid preparation method of SiO2 aerogel sphere, belonging to a field of inorganic metallic materials, in particular to a method of rapidly preparing SiO2 aerogel sphere. Water glass is used as raw material that performs ion exchange to obtain the silicic acid PH=2-3, after added with alkaline catalyst, the silicic acid is added into the hydrophobic oil, and then is mixed to cut into micro liquid drops that are spherically suspended in the oil under the action of surface tension, the silicic acid is mixed until aerogel sphere is generated, afterwards, the oil and the sphere perform solid-liquid separation, and then are cleaned with water to obtain aerogel sphere, the aerogel sphere is soaked by the ethanol and absolute alcohol in sequence to perform solvent exchange to obtain alcohol gel sphere, after dried, aerogel sphere with micrometer or millimeter grade particles can be otained. The invention has low cost, easy and controllable process, mass production, good product quality and wide application prospect in the heat isolation and catalysis fields.

Owner:UNIV OF SCI & TECH BEIJING

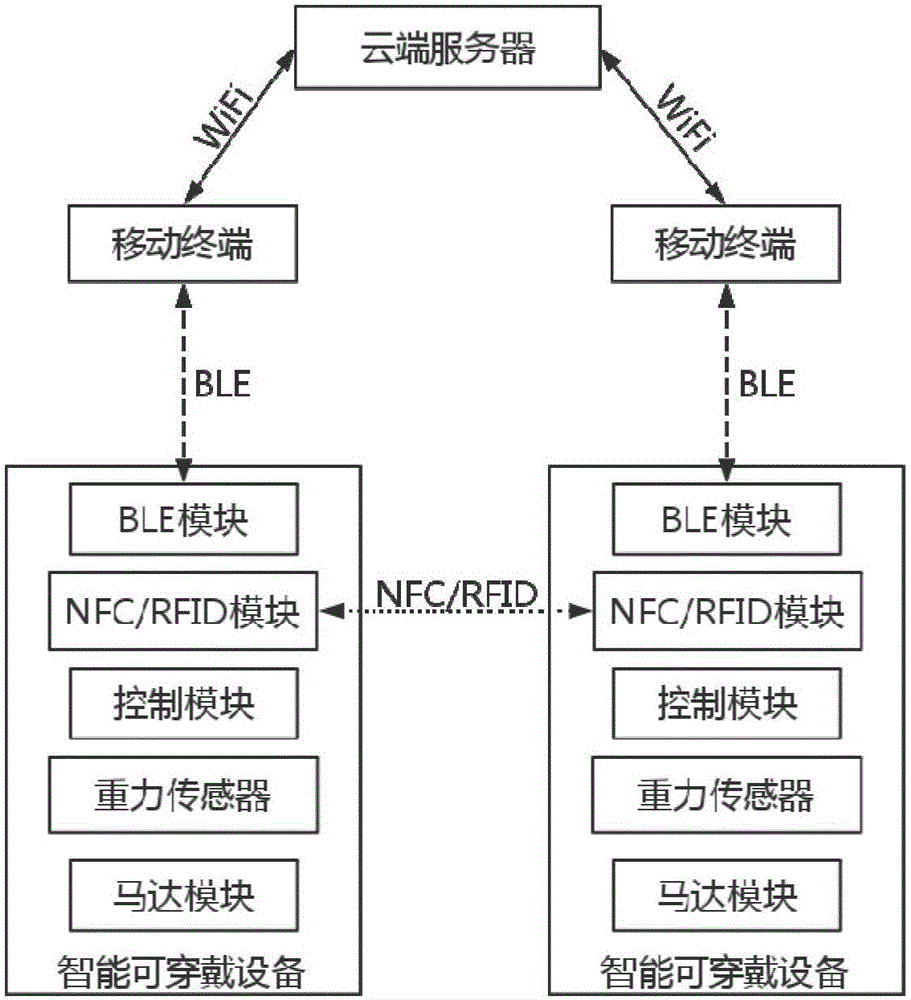

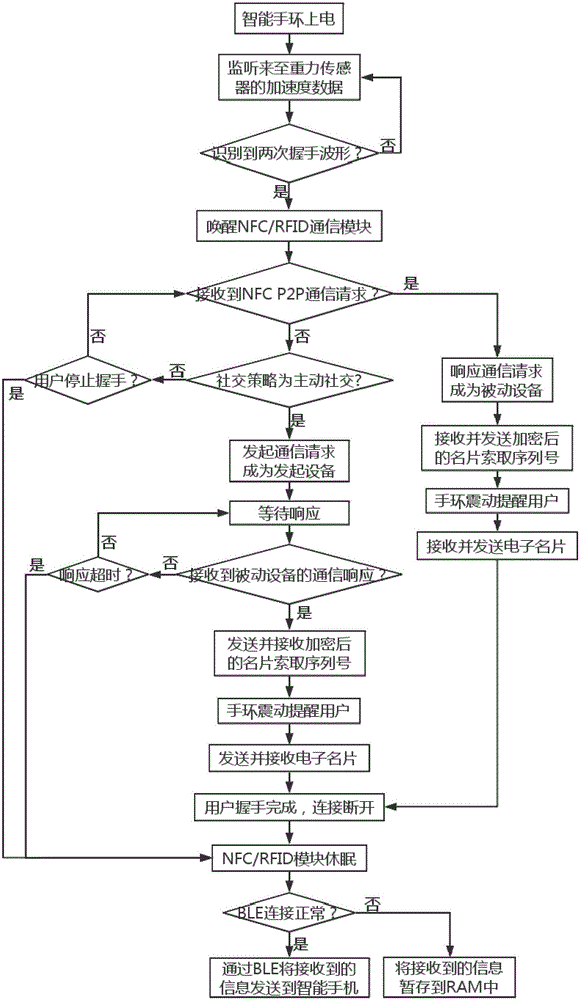

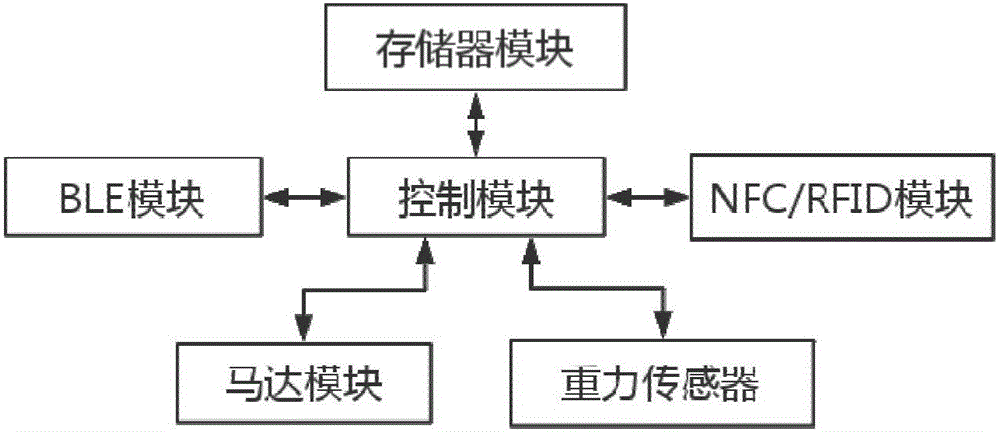

Electronic business card automatic interaction system and method

InactiveCN106060768AReduce the cost of network managementFully excavatedDevices with sensorSubstation equipmentInteraction systemsBluetooth

The invention discloses an electronic business card automatic interaction system and method. The system comprises a cloud server which is used for synchronizing and backing up electronic business cards uploaded by users; mobile terminals which are used for editing, storing and checking the electronic business cards; and intelligent wearable devices which are used for identifying handshake actions of the users, sending and receiving business cards and business card claim serial numbers, and storing the business card claim serial numbers of the users and the received business card claim serial numbers offline. The cloud server is connected with the mobile terminals through a mobile internet. The intelligent wearable devices are connected with the mobile terminals through Bluetooth. Each intelligent wearable device comprises a power supply module, a control module, a memory module, a Bluetooth module, a near field communication module, a gravity sensor and a motor module. According to the system and the method, traditional paper business cards are replaced by the electronic business cards; and the social relationship management costs of the users are reduced.

Owner:SOUTH CHINA UNIV OF TECH

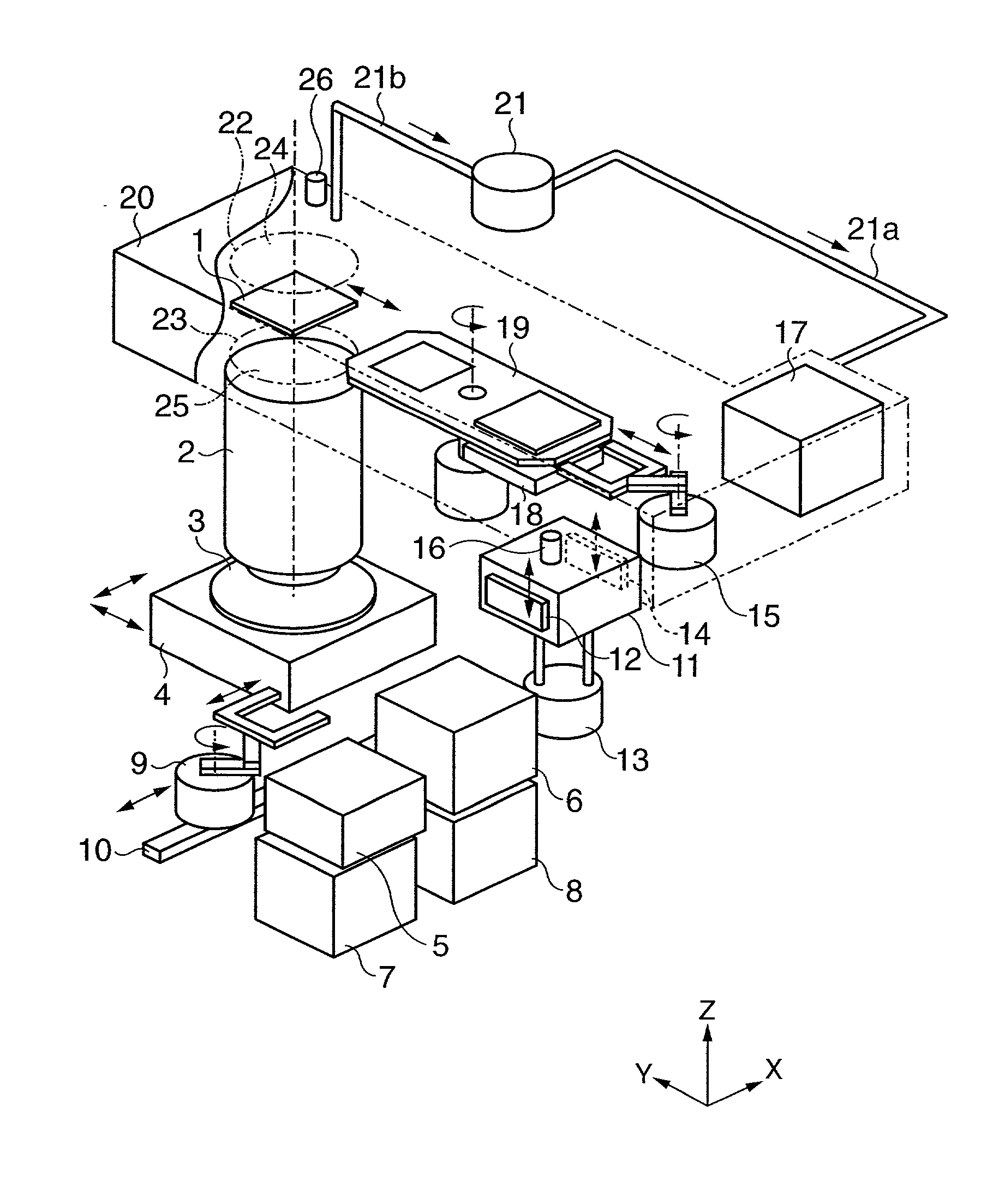

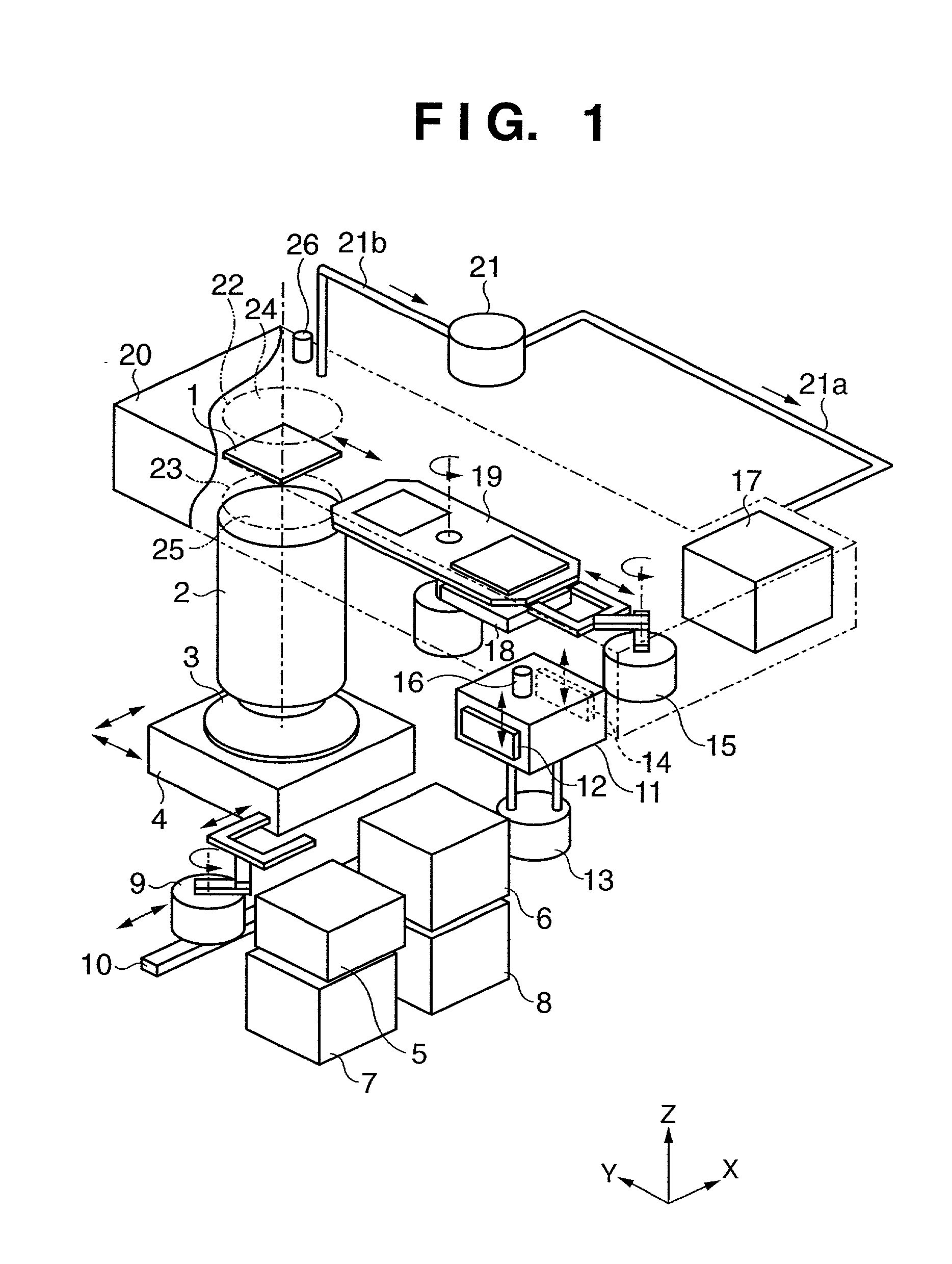

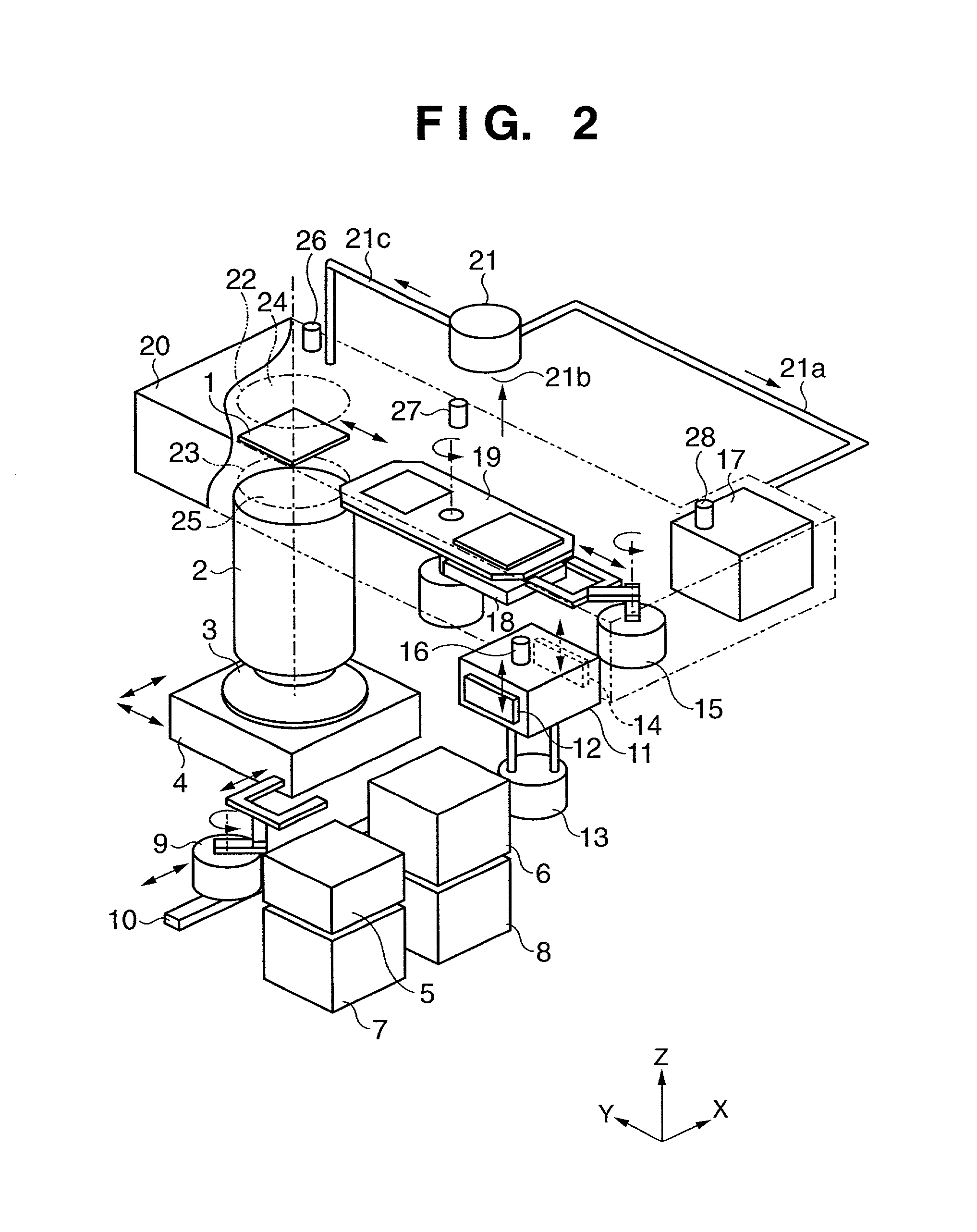

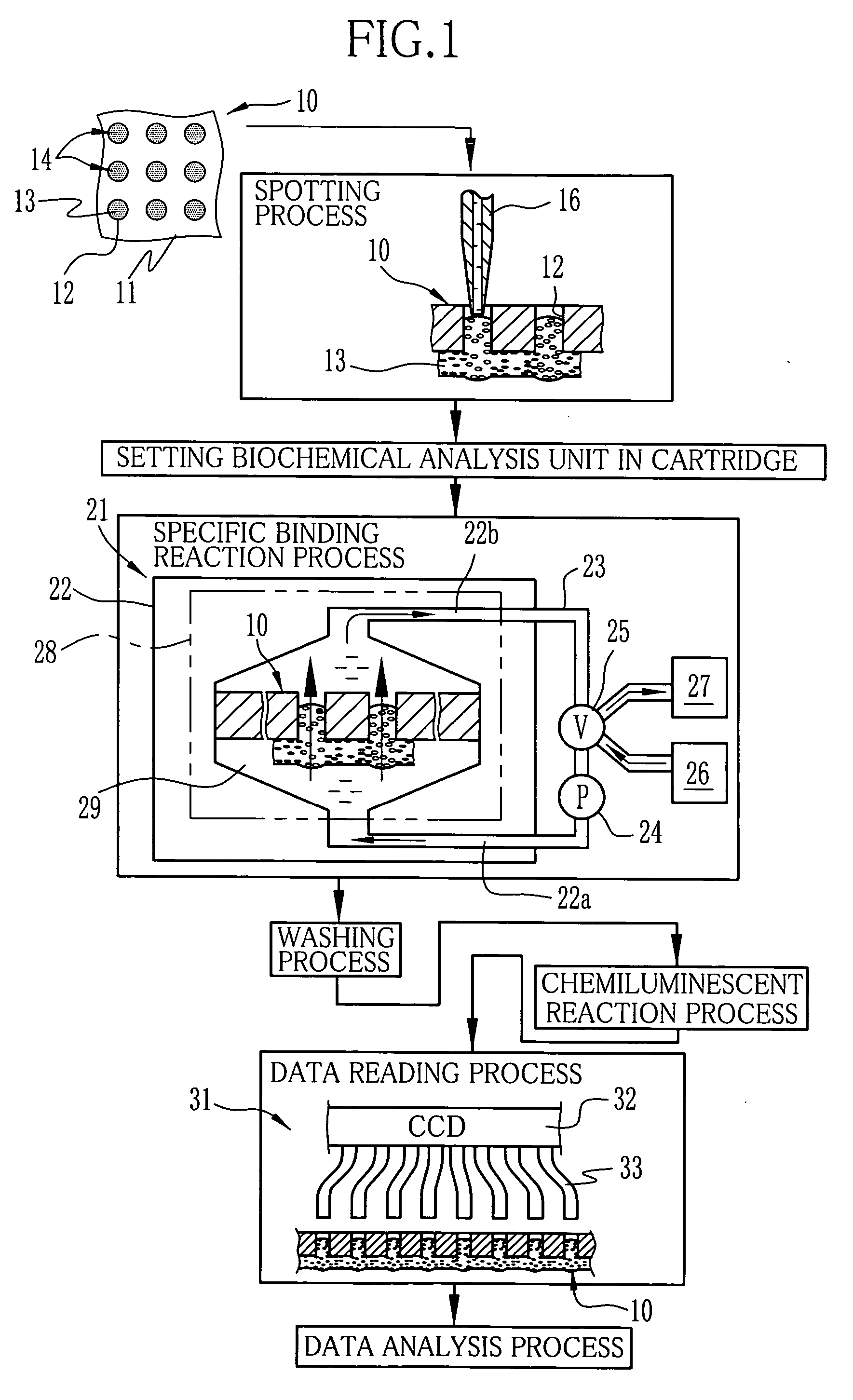

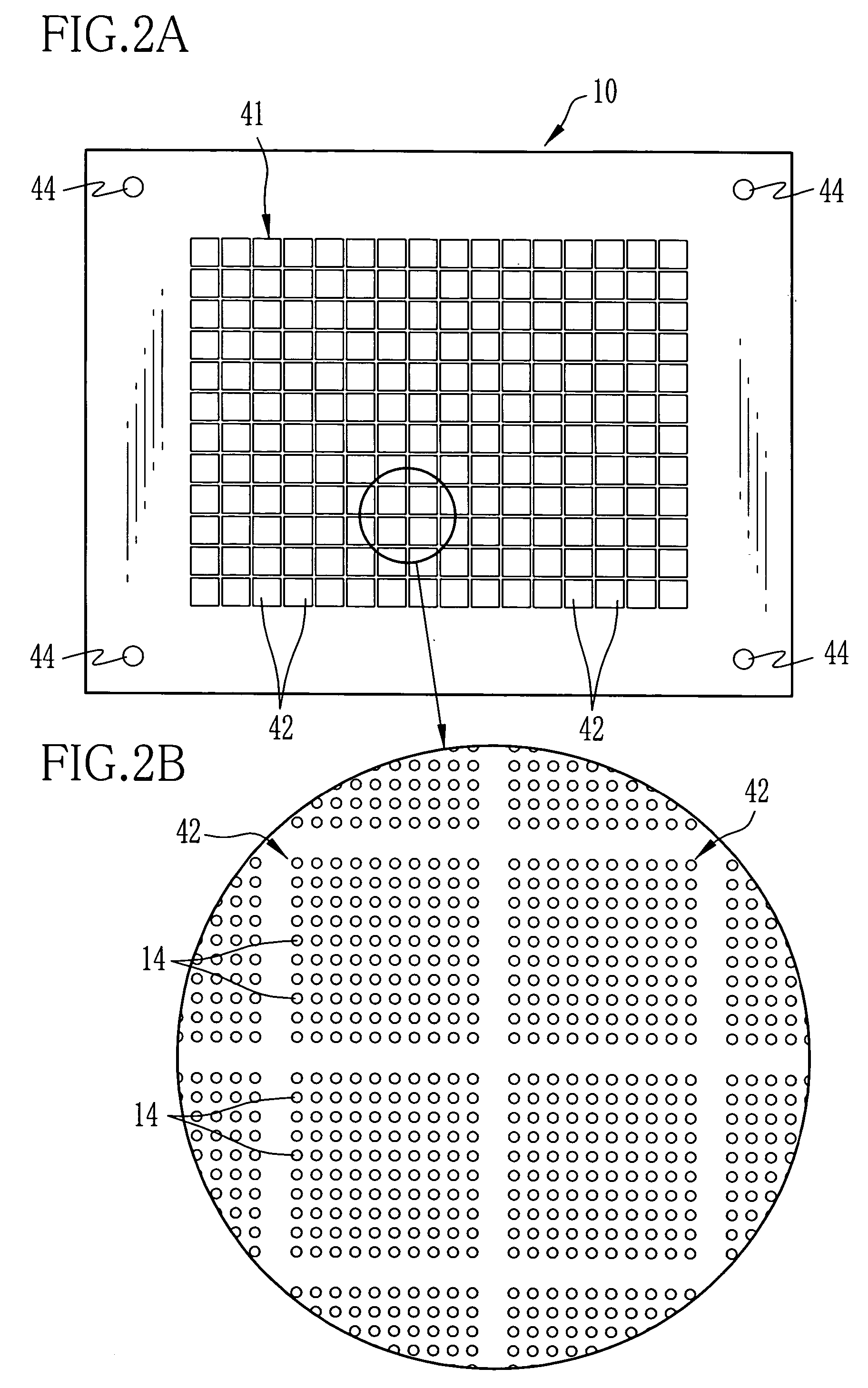

Exposure apparatus and exposure method

InactiveUS20020071105A1Reduce light absorption lossShort master exchange timeSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMechanical engineeringAtmosphere

An exposure apparatus for transferring a pattern on a master to a substrate via an optical system includes a first housing for surrounding the exposure position of the master, a second housing for stocking the master, and a third housing for transferring the master between the inside and outside of the first housing. The interior of each housing is controlled to a predetermined atmosphere.

Owner:CANON KK

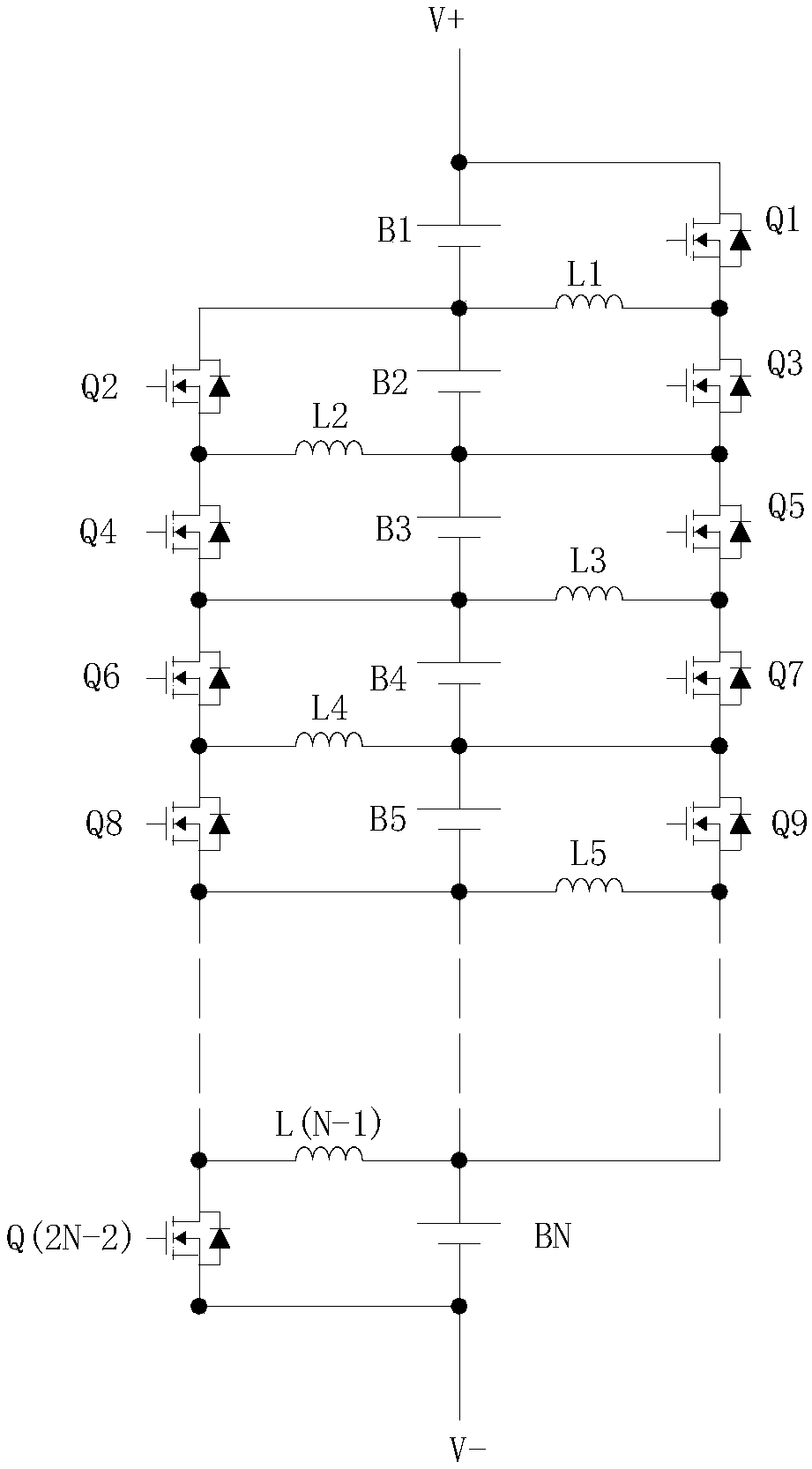

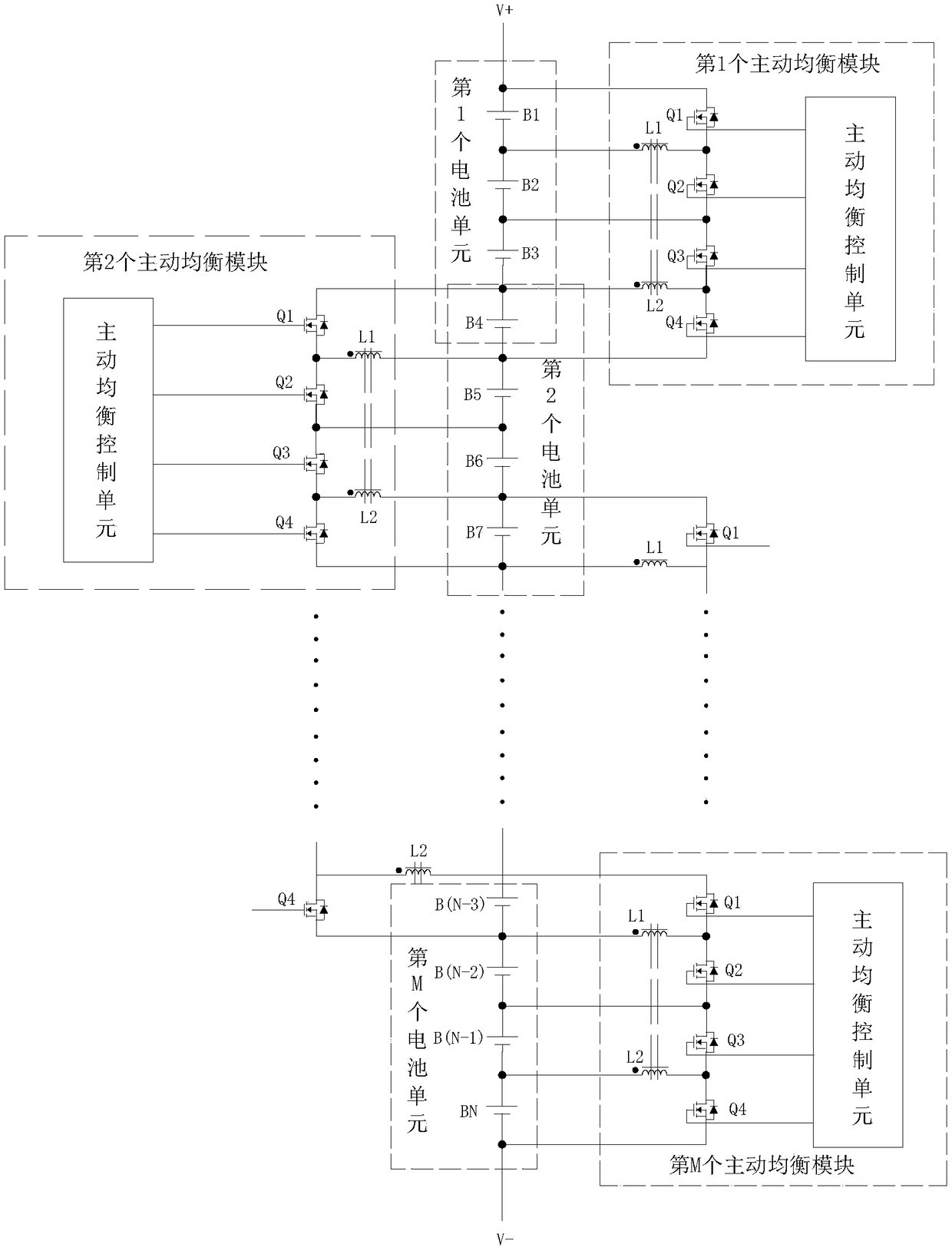

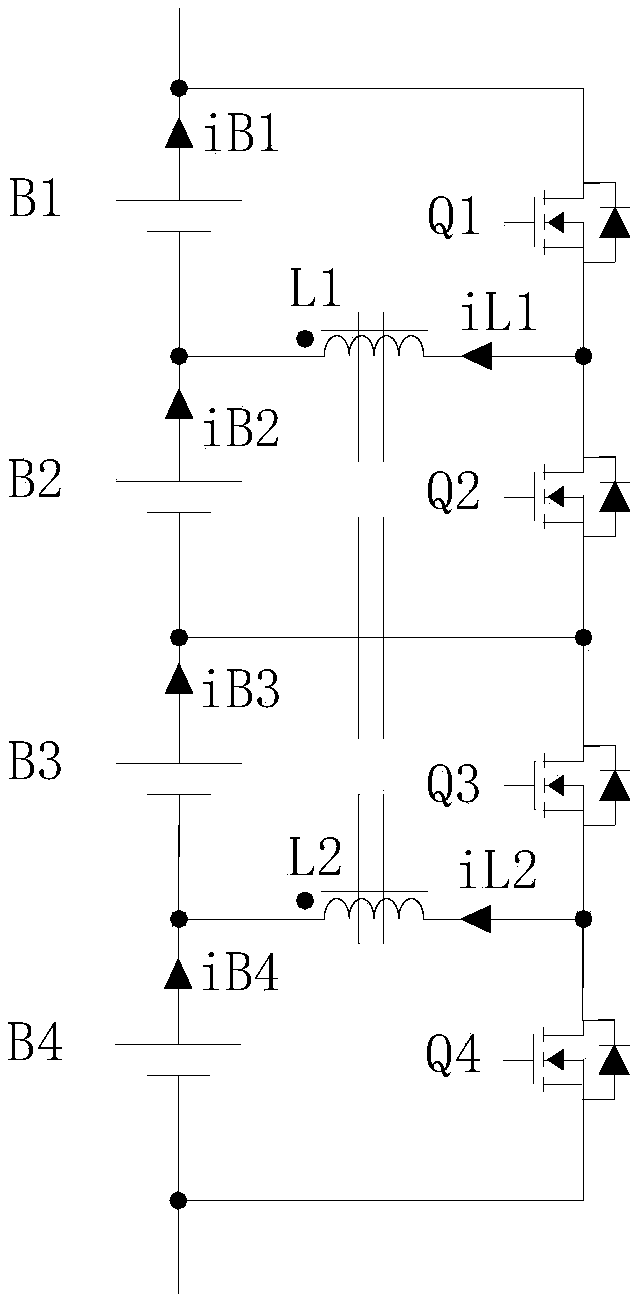

A system and method for modular active equalization of series battery packs

InactiveCN109038760AFewer switching devicesSimple topologyCharge equalisation circuitSecondary cellsTransformerOperation mode

A management apparatus for series battery includes a conversion unit electrically connected to a plurality of series cell, wherein that conversion unit includes a switch assembly configured to controla closed state of a plurality of loops correspond to the plurality of single cells; And a charging, discharging and voltage transformation assembly configured to operate in a charge, discharge or transformer mode to achieve power dispatch between adjacent and non-adjacent cell units; The battery management apparatus further includes a control unit electrically connected to the conversion unit, configured to detect a state of the battery, and control a state of the switch assembly and an operation mode of the charge-discharge and transformer assembly. Inside each battery cell, the power exchange between the batteries is realized by controlling the power switch tube and the transformer, and the power exchange between adjacent battery cells is realized by sharing a single battery. The time of the power exchange is short, and the energy transfer loss is small.

Owner:LEN TECH LTD

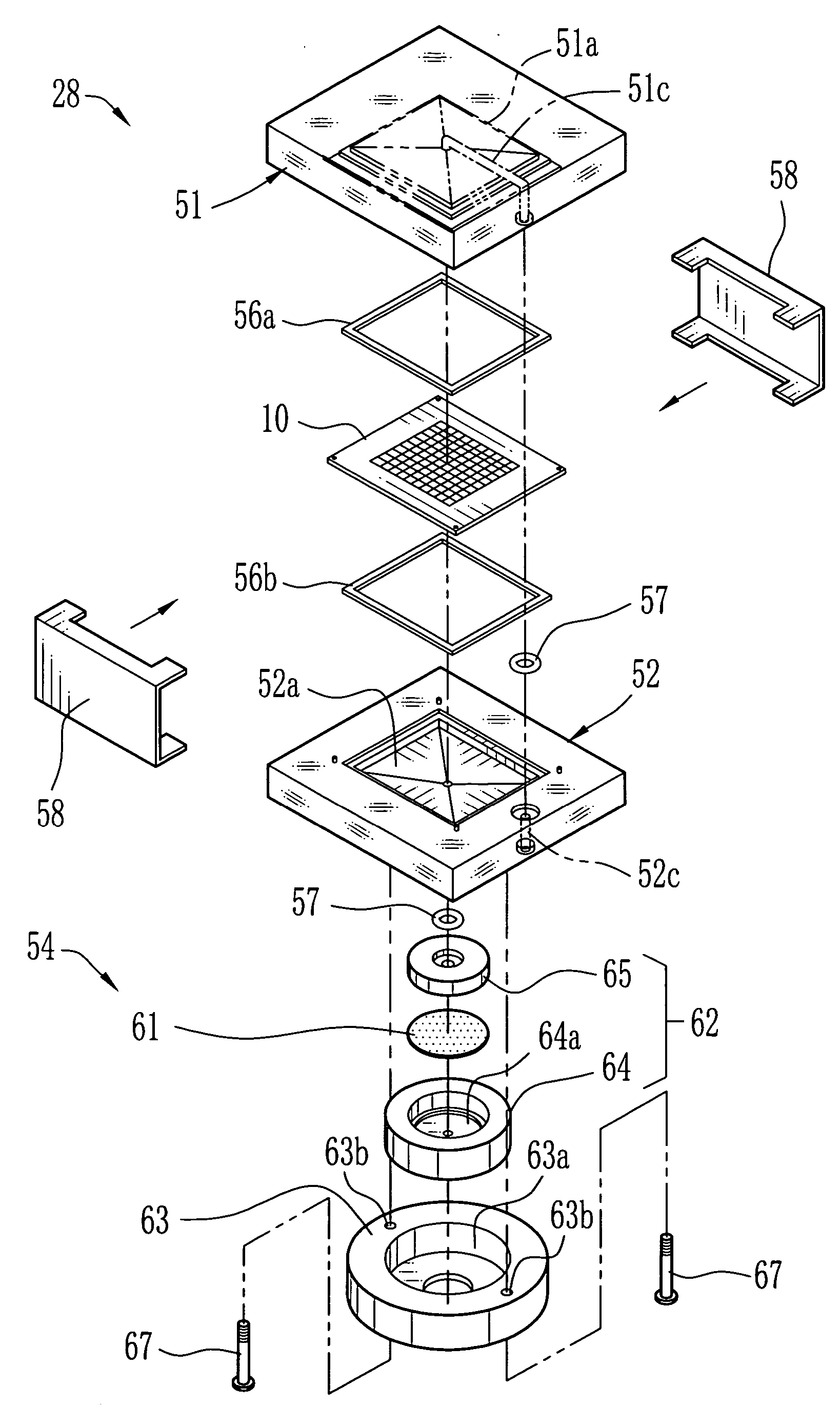

Cartridge for biochemical analysis unit

InactiveUS20050070012A1Avoid loadShorten the timeBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringEngineering

A cartridge includes a cartridge main body and a filter unit. The cartridge main body contains a biochemical analysis unit of flow-through type, and includes a chamber into which a reaction solution is injected. The filter unit is used for the filtrating the reaction solution and fixed by screws to a bottom of the cartridge main body. The biochemical analysis unit is removably loaded onto a reactor main body in a situation that the cartridge is loaded. In setting the cartridge, the biochemical analysis unit and the filter are loaded, and therefore the loading mistake is prevented and the time for exchange of the filter is reduced.

Owner:FUJIFILM HLDG CORP +1

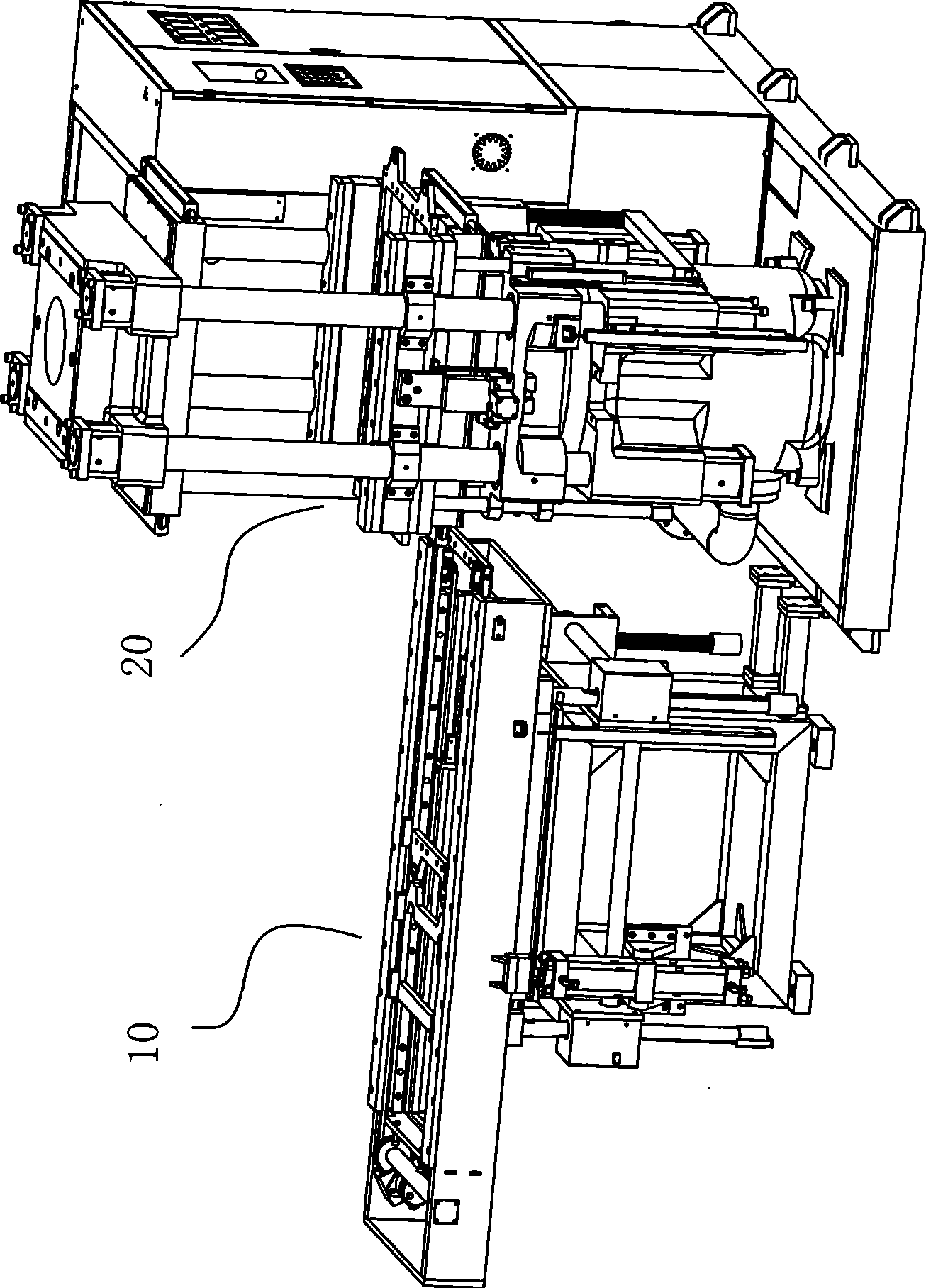

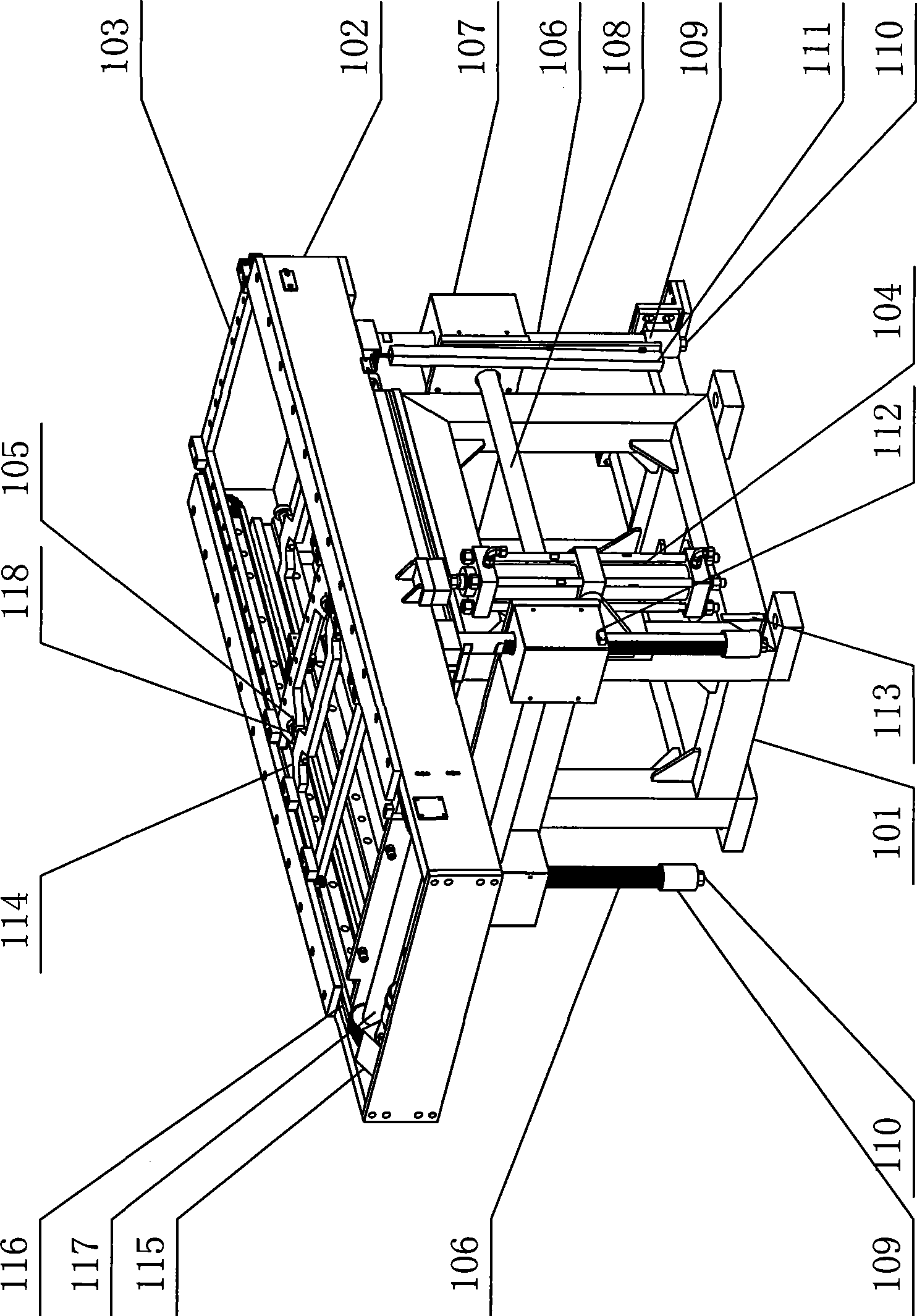

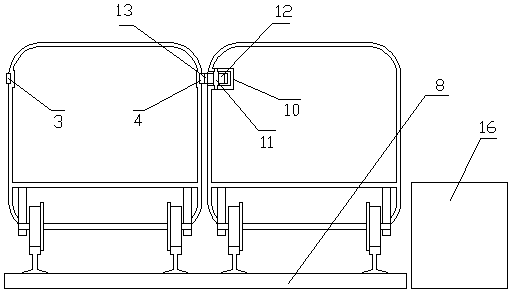

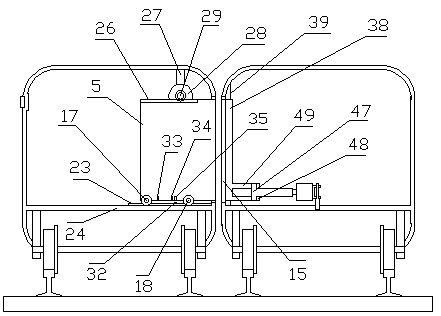

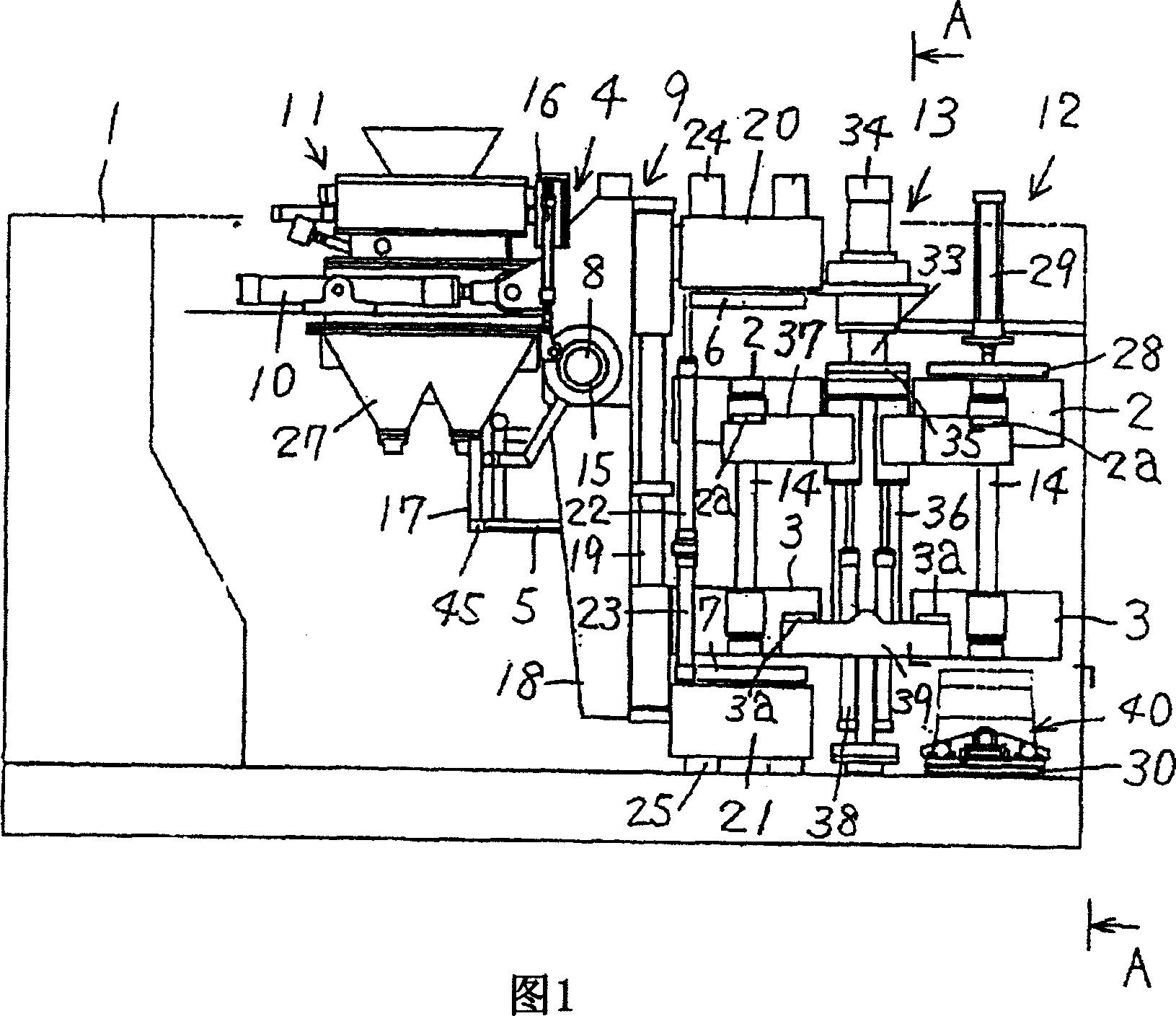

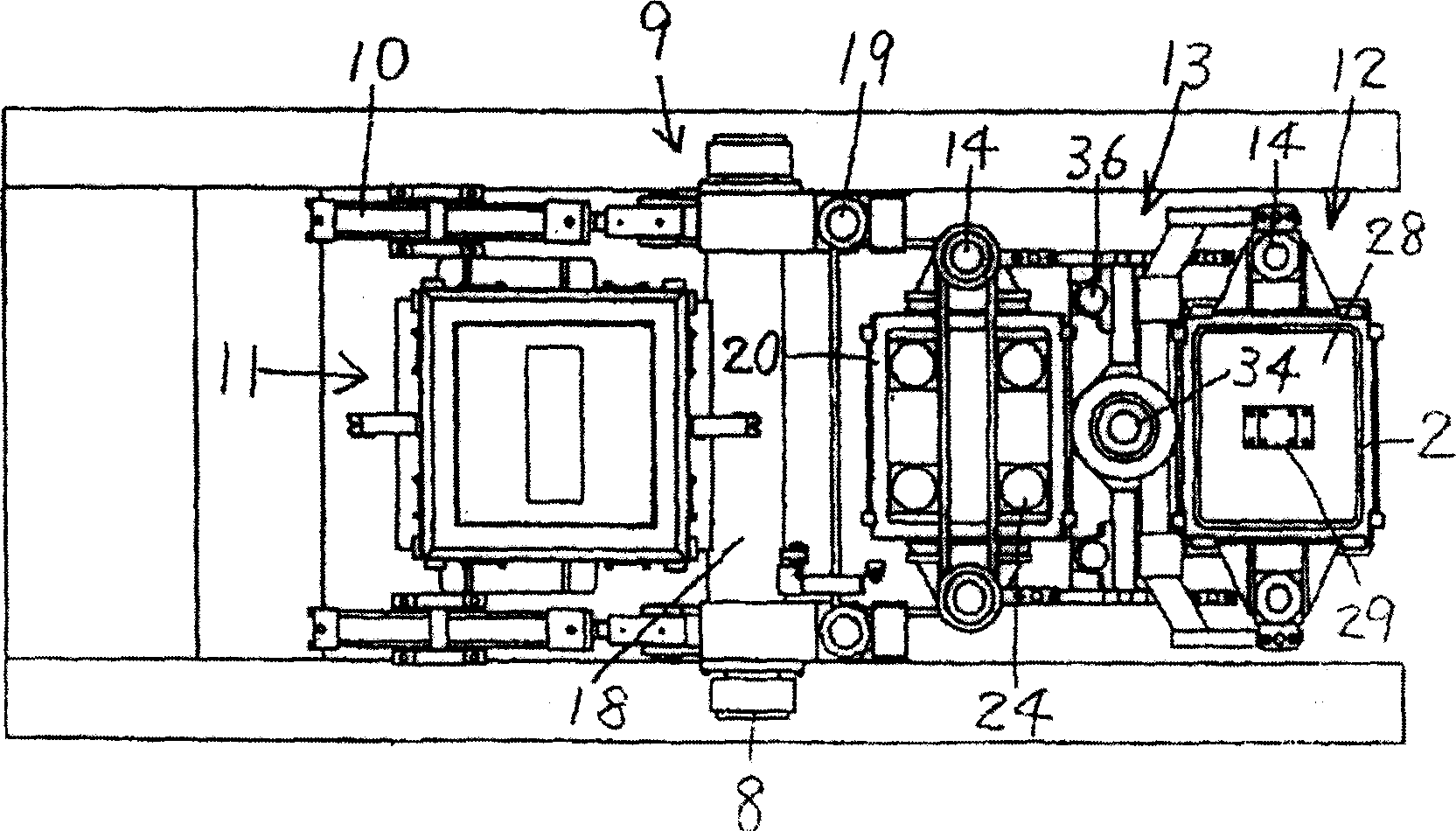

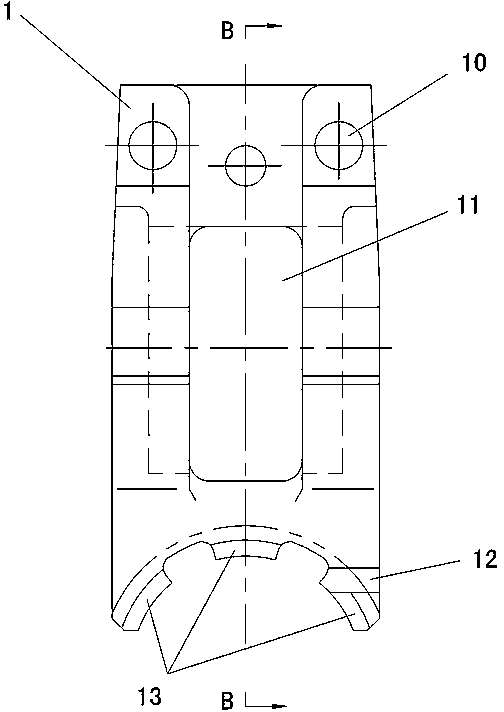

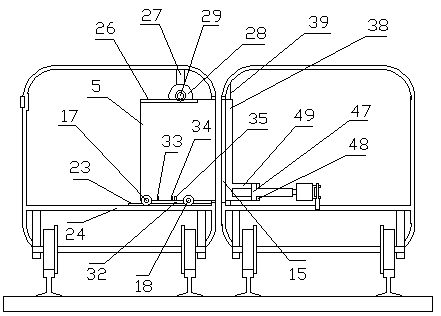

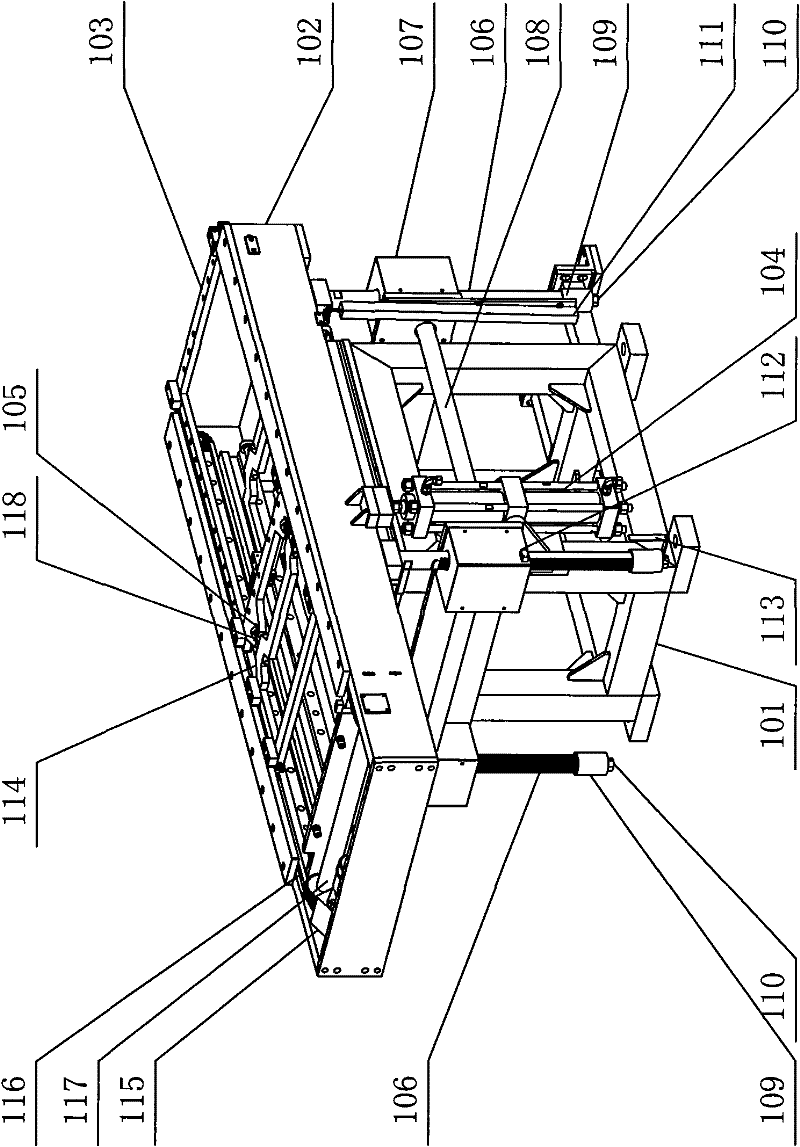

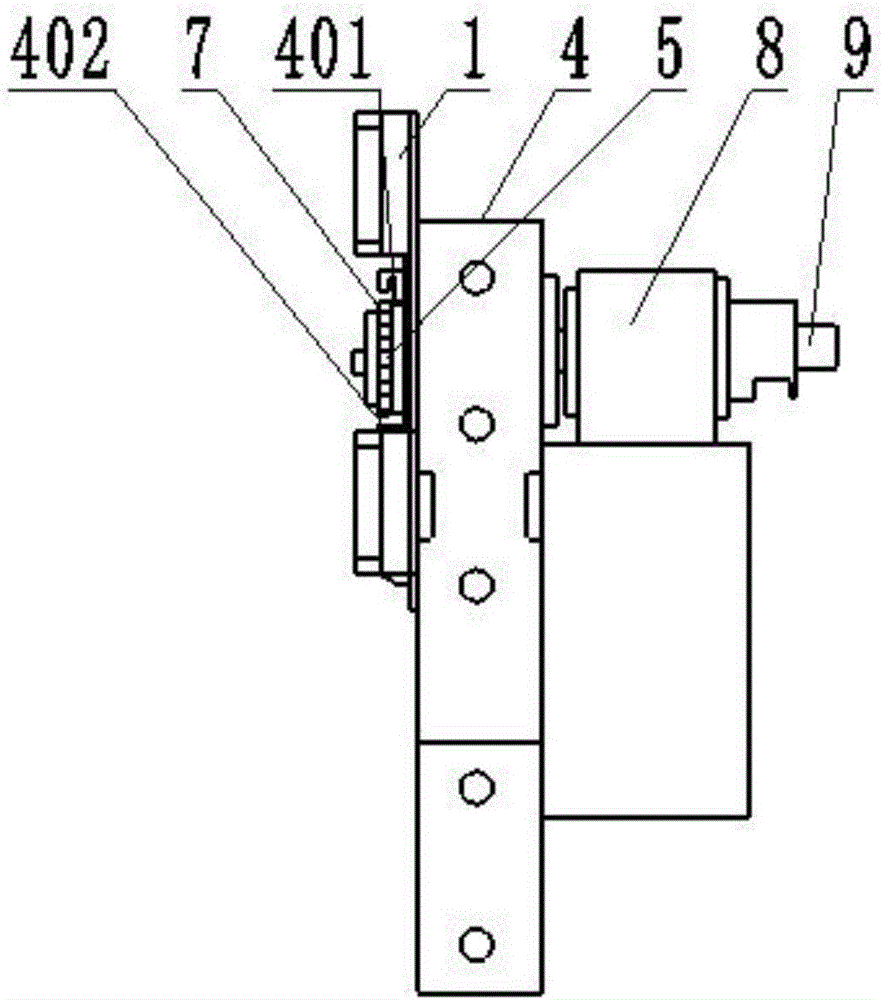

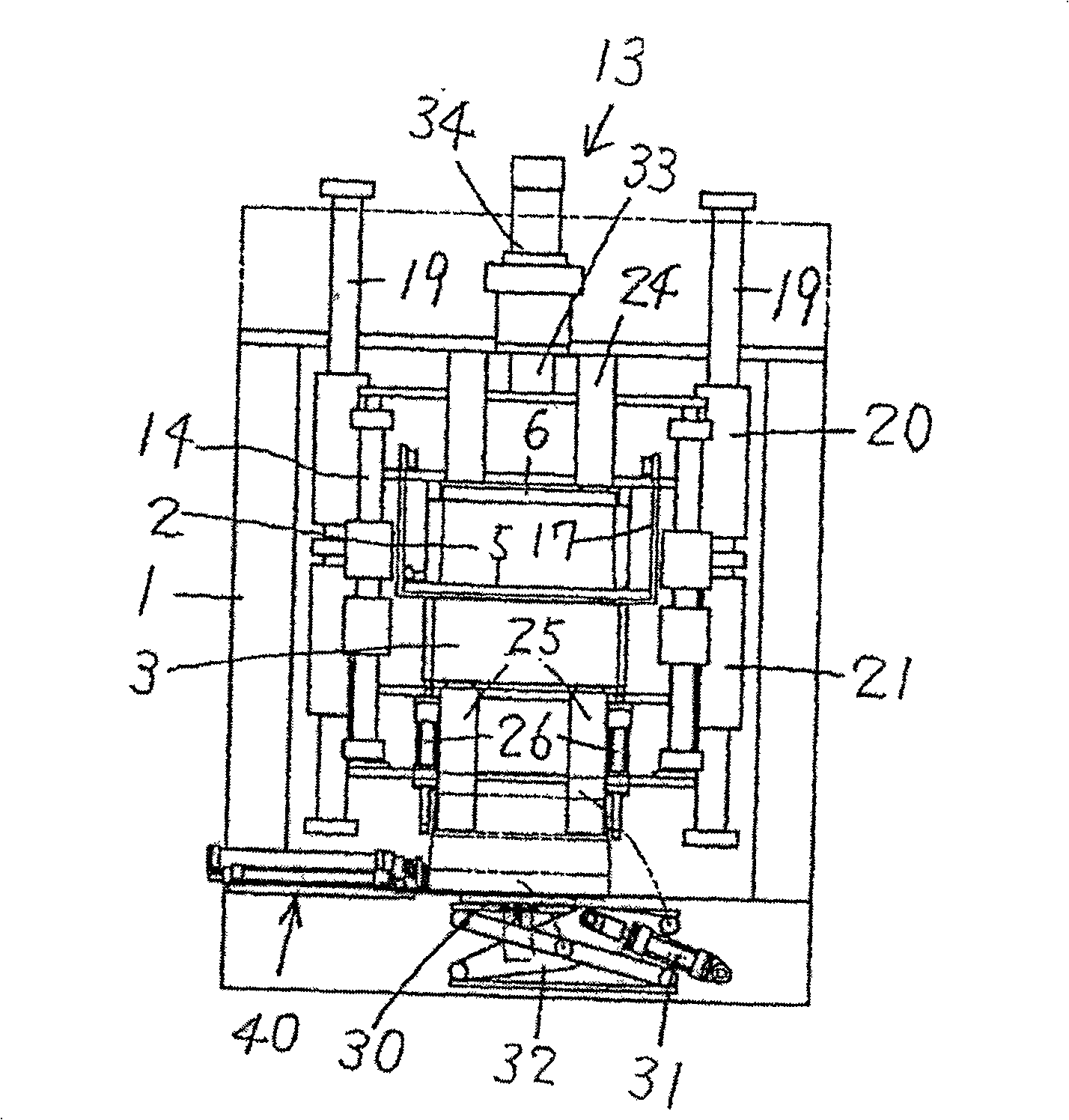

Multi-station framework switching structure of injection machine

InactiveCN101462347AAccurate docking positioningAvoid the possibility of inaccurate alignmentButt jointInjection molding machine

The invention belongs to an injector multiple-station mold plate exchange structure, which comprises a moving mold component and a hanging mold component, wherein the moving mold component comprises a moving mold bracket and a moving mold seat positioned on the moving mold bracket. A mold plate frame used for supporting a lower mold plate is arranged on the moving mold seat and a supporting plate used for the horizontal displacement of the lower mold plate and the mold plate frame is also connected to the mold plate frame. A moving mold seat lifting device capable of driving the moving mold seat to move up and down, a mold plate frame exchange device and a moving mold seat positioning device are arranged on the moving mold bracket. The hanging mold component comprises a static mold plate and a dynamic mold plate, wherein a hanging mold seat used for supporting the mold plate frame is arranged between the still mold plate and the dynamic mold plate. The mold plate frame which can be exchanged with the mold plate frame on the dynamic mold seat is arranged on the hanging mold seat and a hanging mold seat lifting device, a horizontal moving device making the hanging mold seat move back and forth and a hanging mold seat positioning device are arranged below the mold plate frame. The mold plate exchange structure has the advantages of compact structure, high butt joint precision, precise and stable repeated butt joint and positioning precision and safe and reliable use.

Owner:DEKEMO HUADA MECHANICAL DONGGUAN +1

Silver/titanium oxide-zirconium phosphate intercalated composite material and its preparation method and use

InactiveCN108077310AGood dispersionIncrease loadBiocideMaterial nanotechnologySolubilityIon exchange

The invention provides a silver / titanium oxide-zirconium phosphate intercalated composite material and its preparation method and use. The preparation method utilizes zirconium oxychloride, phosphoricacid, tetrabutyl titanate and silver nitrate as raw materials and comprises feeding tetrabutyl titanate to a position between layers of zirconium phosphate through a supercritical method under control of a temperature, pressure and reaction time, carrying out complete hydrolysis to obtain a titanium hydroxide-zirconium phosphate intercalated composite material containing titanium hydroxide dispersed and supported between layers of zirconium phosphate, loading silver through an ion exchange method and carrying out calcination to obtain the silver / titanium oxide-zirconium phosphate intercalatedcomposite material. The preparation method is simple and controllable, fully utilizes supercritical CO2 fluid solubility to enlarge the layer distance and improves the dispersibility and the load rate of the titanium oxide and silver on the zirconium phosphate carrier. The preparation method is efficient and rapid. The silver / titanium oxide-zirconium phosphate intercalated composite material canbe used in the fields of antibiosis and catalysis.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

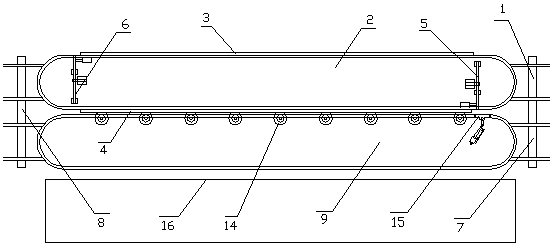

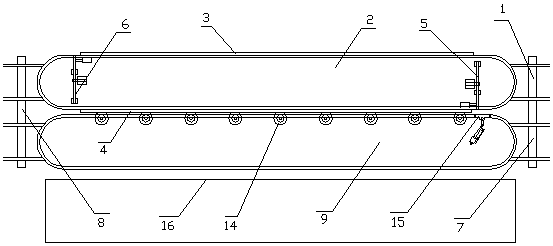

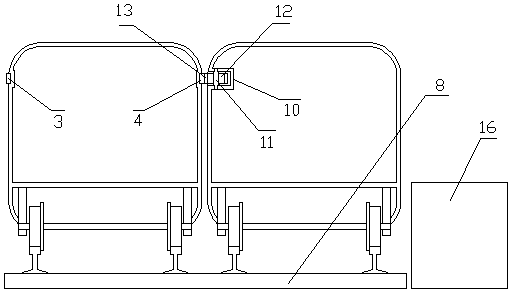

Parallel access non-stopping high-speed train

ActiveCN109131422AReduce the impactShort exchange timeRailway auxillary equipmentButt jointEngineering

A parallel access non-stopping high-speed train includes a running track, a running train, an anti-collision track, an electronically-controlled locking door, a platform track, a platform train, an anti-collision pulley, an electronically-controlled flap, an intelligent controller and a waiting platform., wherein an anti-collision pulley and an anti-collision track are arranged on the upper end ofthe running train and the platform train, and the anti-collision pulley slides on the anti-collision track during the parallel butt joint or separation of the two trains, so that a stable distance of2cm is maintained between the running train and the platform train, and the two trains are prevented from colliding and rubbing each other; when the two trains are butted together, the intelligent controller adjusts the speed of the train to synchronize the two trains, and the electronically controlled locking door of the running train penetrates into the electronically controlled valve of the train on the platform to mechanically lock the two trains into an integrated double train. The electronically controlled locking door acts as a windshield to reduce the influence of the outdoor air flowon the indoor of the double trains in high-speed operation. When boarding and disembarking passengers are exchanged, the front and rear doors of the integrated twin trains are fully opened, which canmeet the requirements of larger passenger flow.

Owner:临沭县济才人力资源服务有限公司

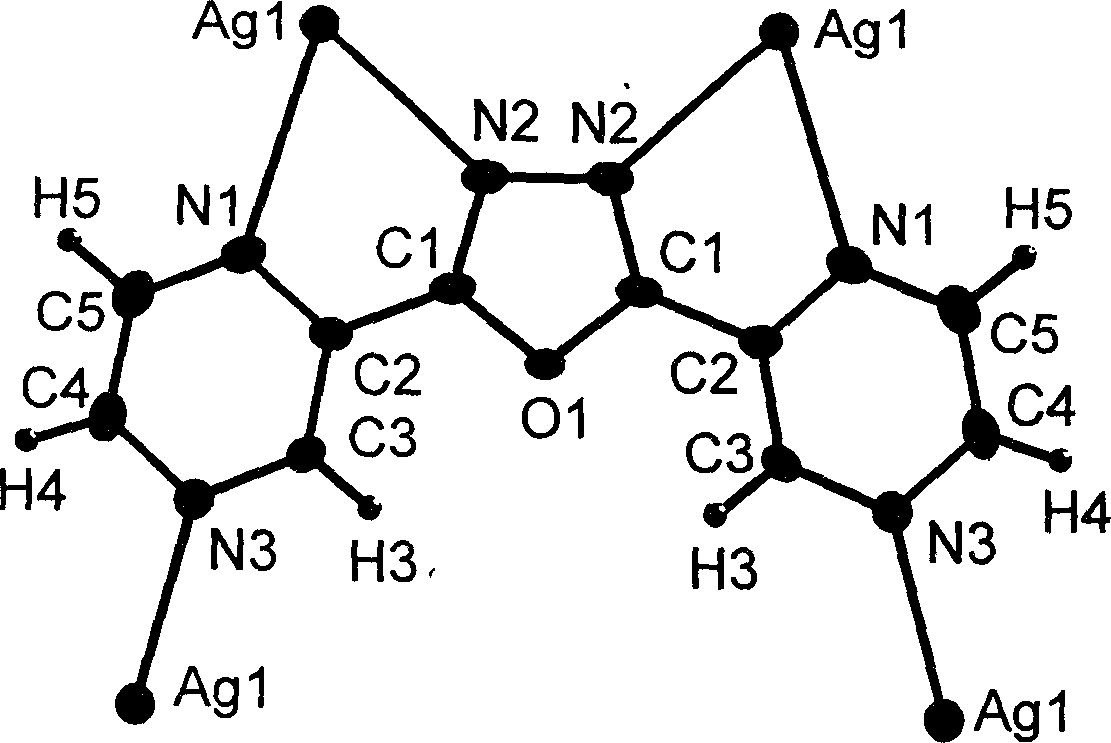

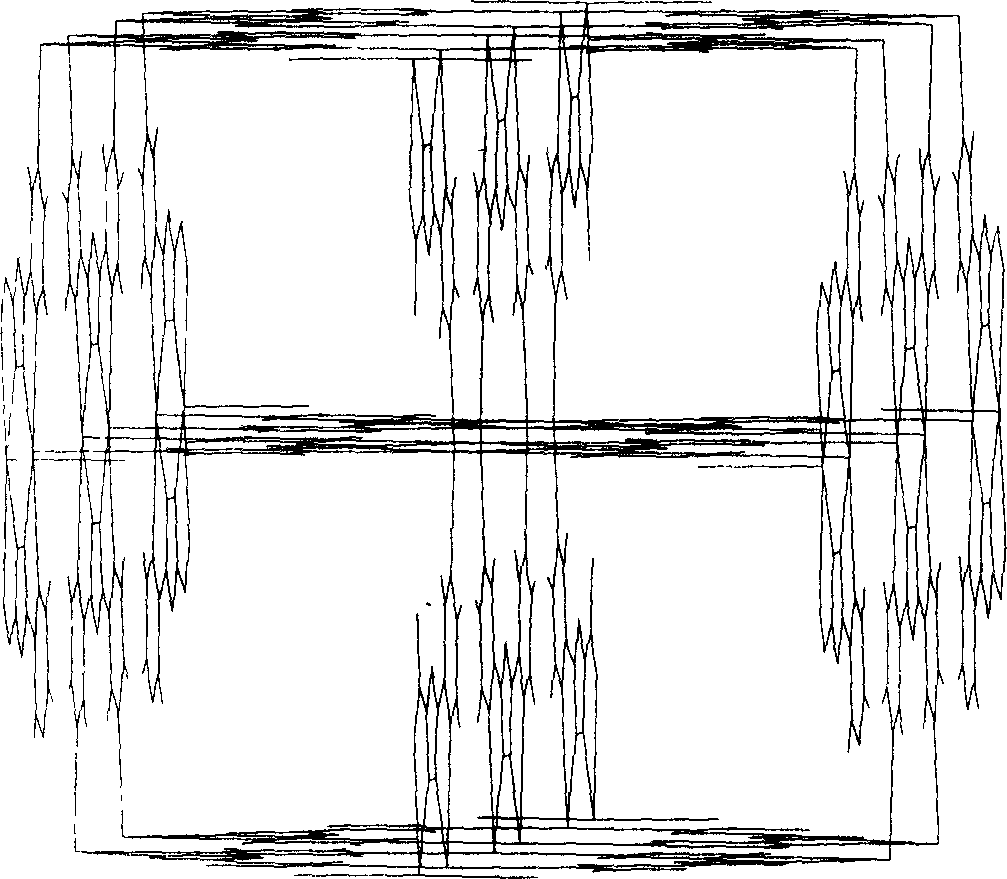

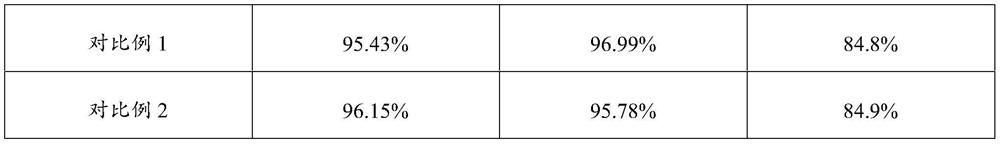

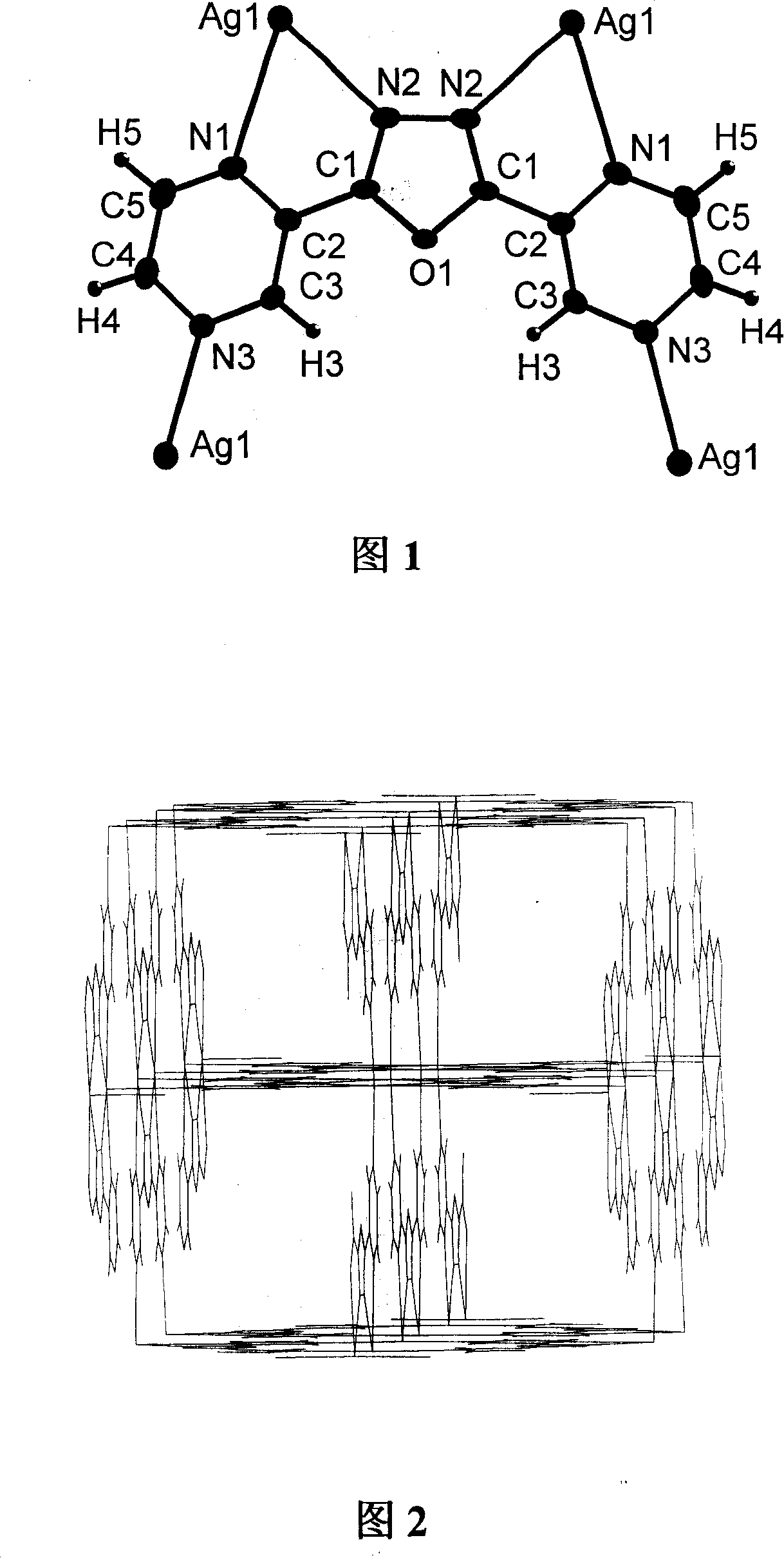

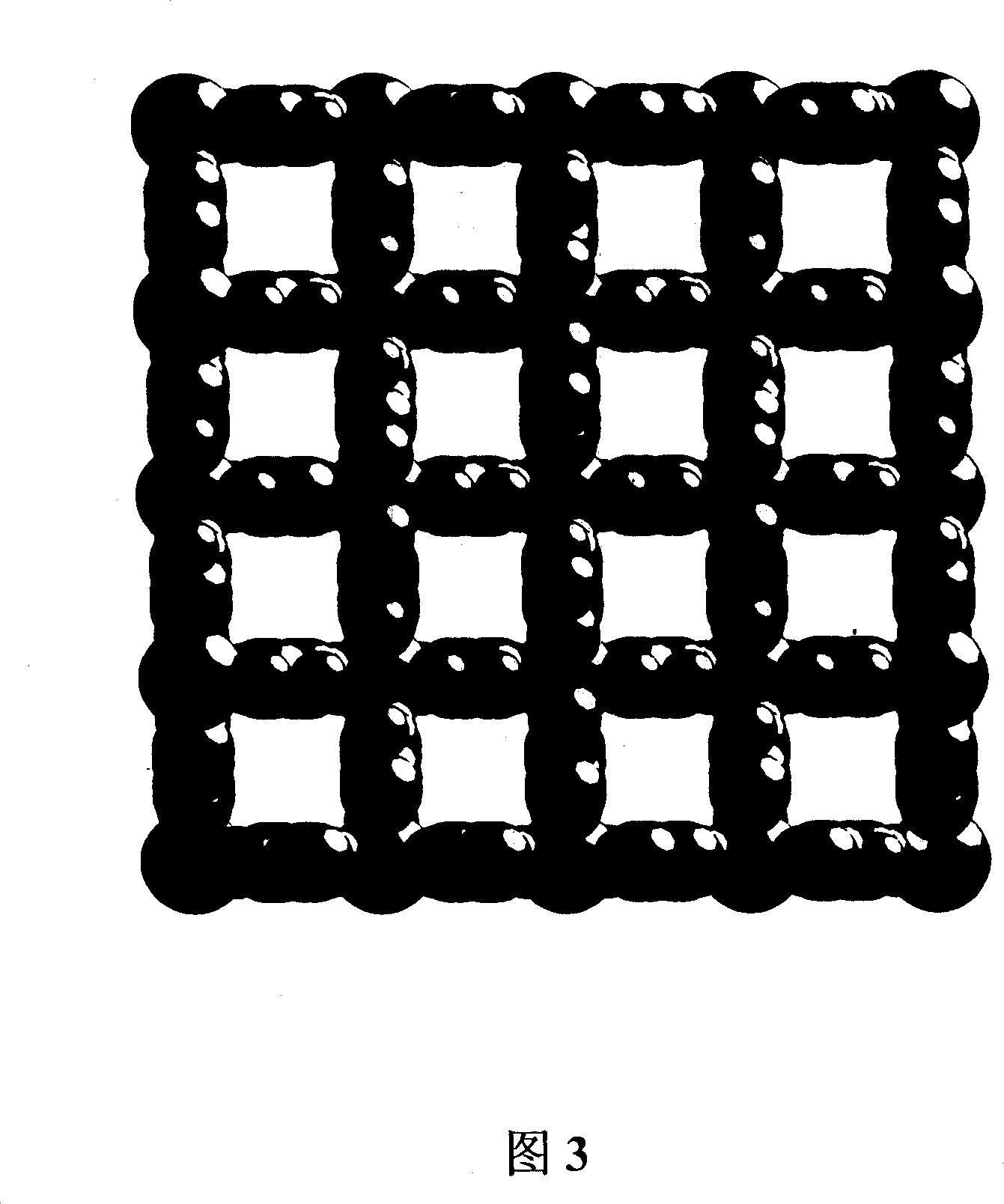

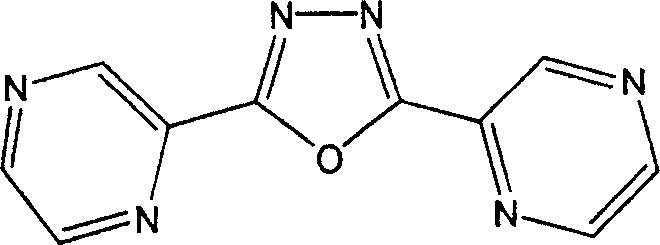

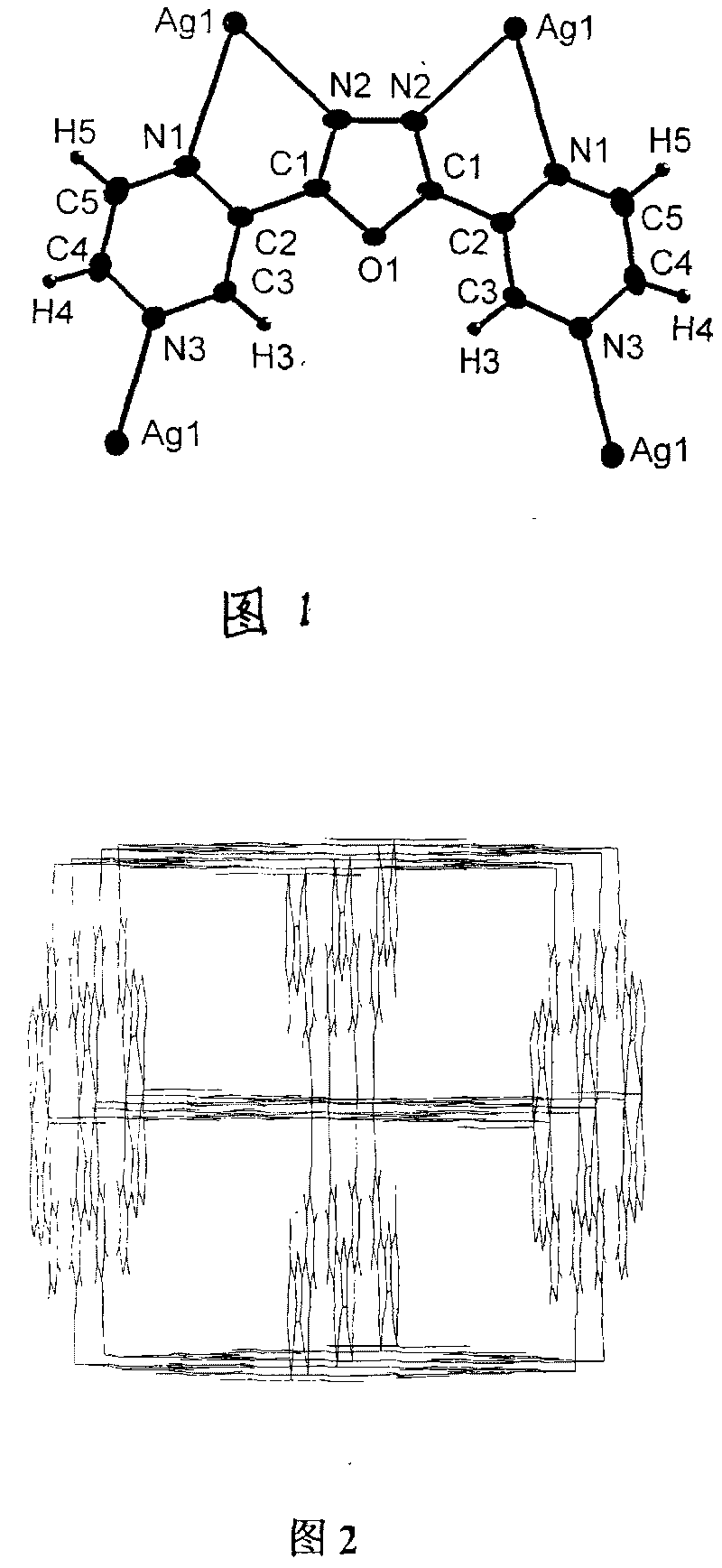

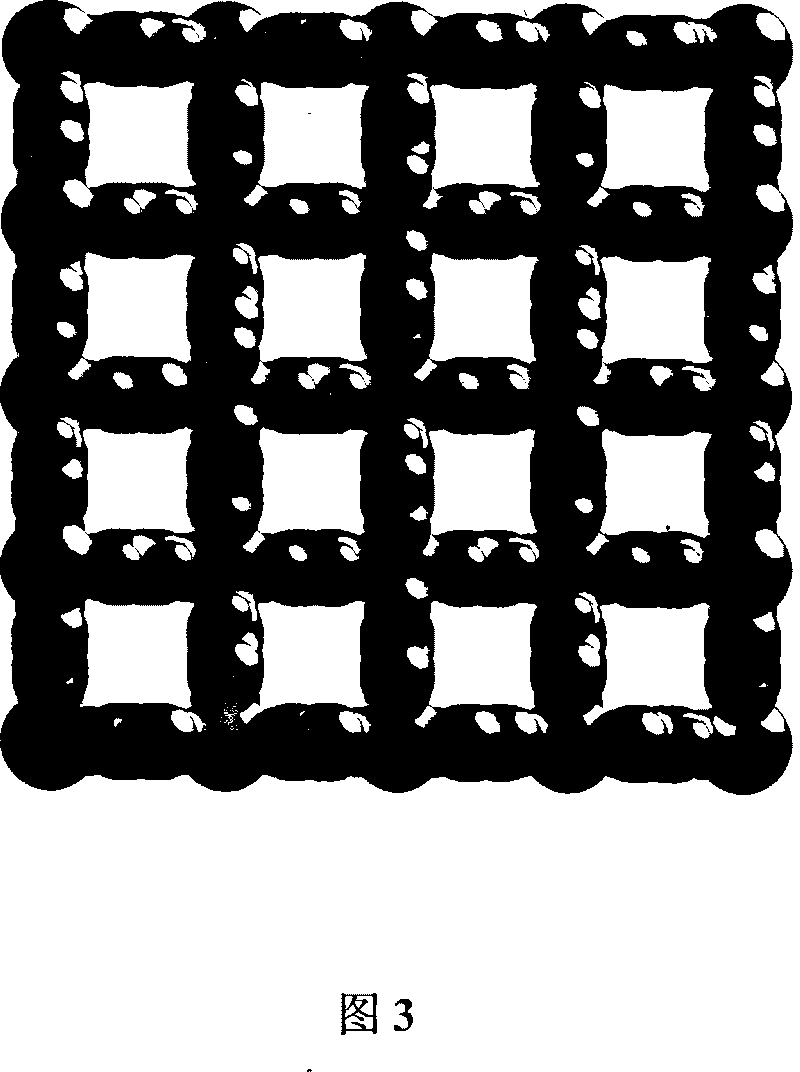

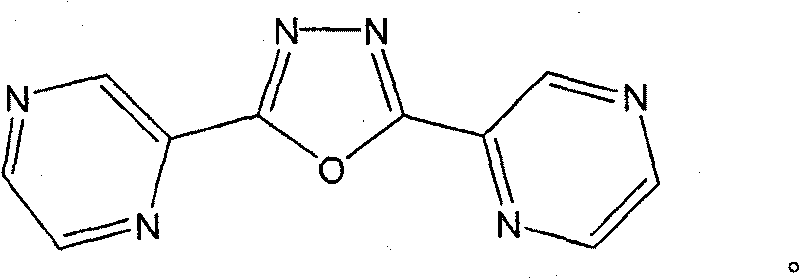

Novel ion-exchange material, its preparation and application

InactiveCN1698963AStrong ion exchangeSynthetic method is fastOrganic anion exchangersInorganic anion exchangersIon exchangeMolecular materials

This invention relates to a new ion exchange material, in addition to its preparing and uses, which belongs to the mineral-organic hybridization function molecular material and synthetic technology. The material is a coordinated polymer having the same three-dimensional opening cage, which can prevent the major cavity structure changing with the anion. The material is based on double piperazidine bridge organic ligand L with oxdiazole ring and Ag1 mineral metal salt, and its general formula is {[Ag(L)]X*solution}n, wherein the molecular formula of L is: C10H6N6O, and X is AsF6-,CF3SO3-, or SbF6- anion.

Owner:TIANJIN NORMAL UNIVERSITY

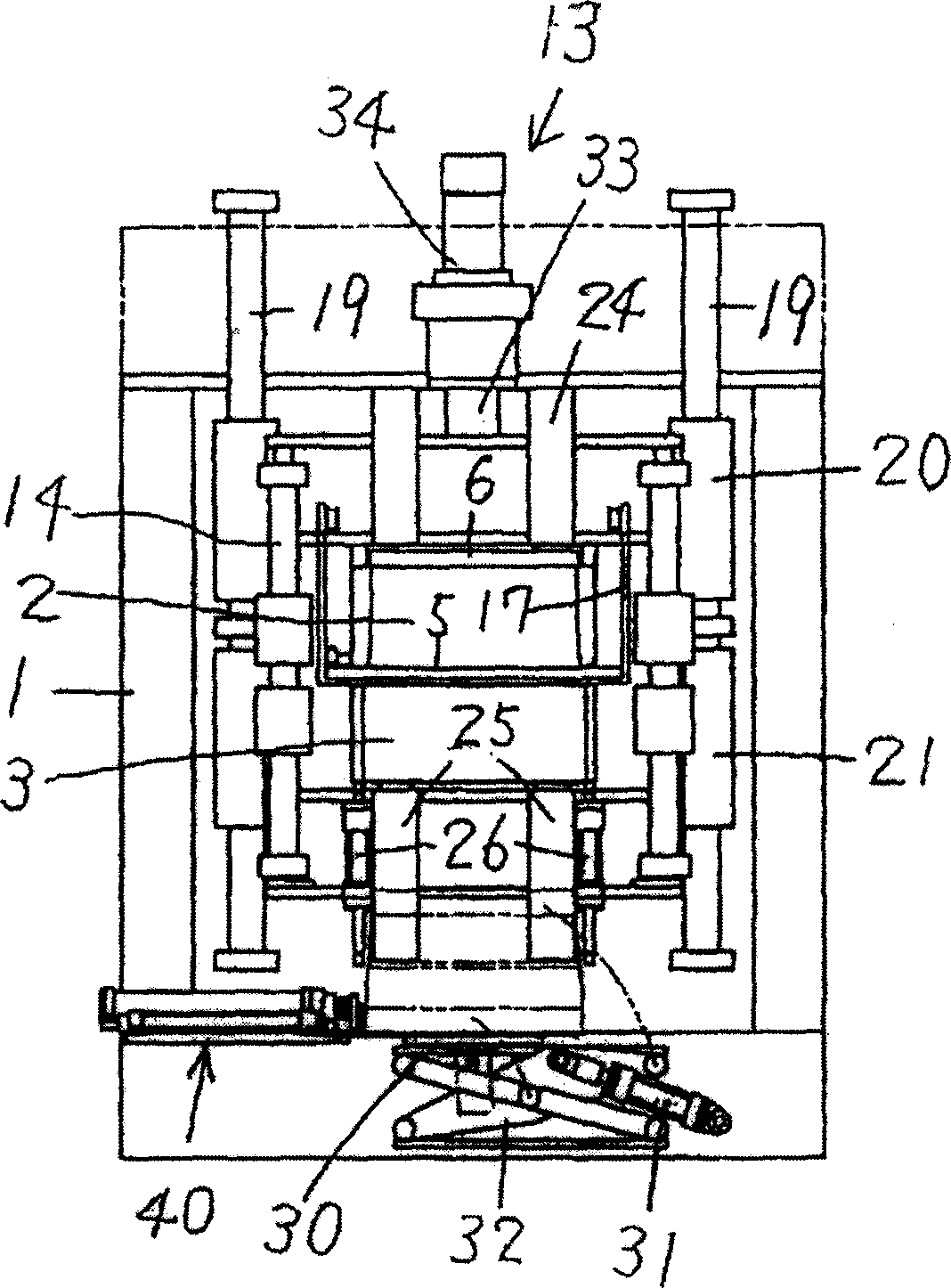

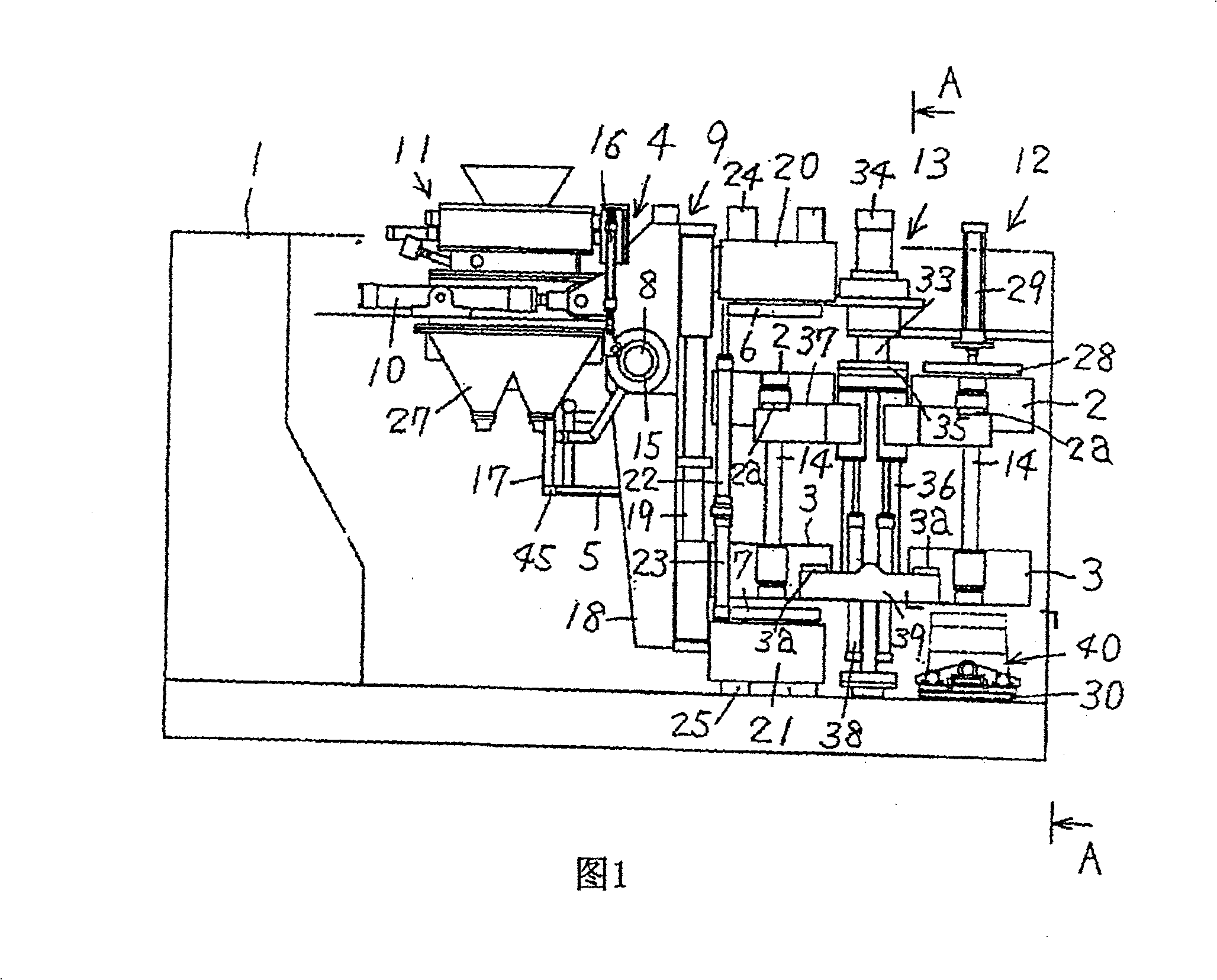

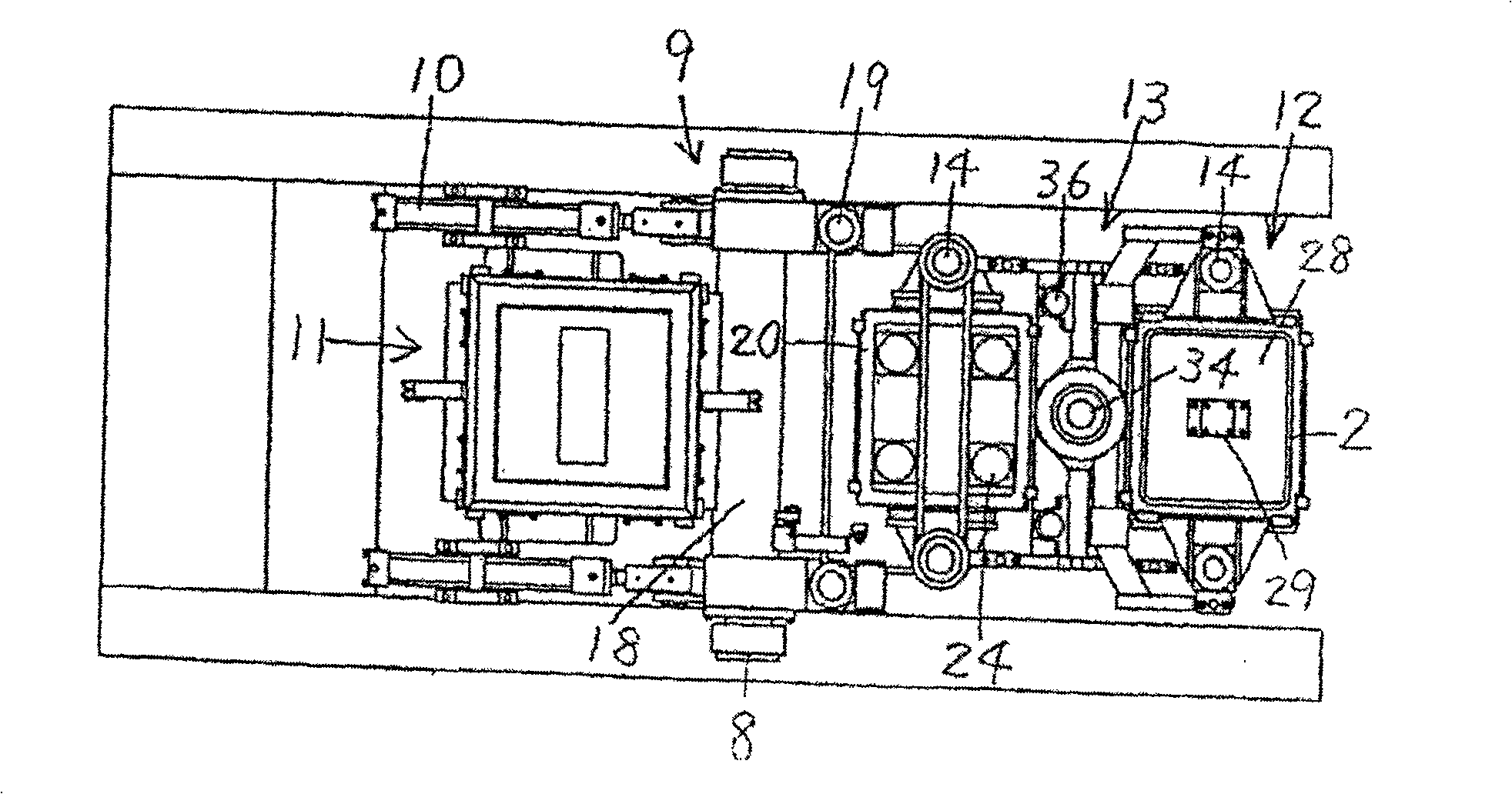

Method and device for forming flaskless cope and drag, and method of replacing matchplate

The invention provides a method and a device for manufacturing an upper and lower casting mold without a sandbox. The double-sided templates are clamped by the horizontal mold-making upper box and mold-making lower box with sand blowing inlets on the side walls; the upper and lower extrusion devices are respectively inserted into the mold-making upper box and the mold-making lower box without double-sided templates. The opening of the upper and lower mold-making spaces is formed; a pair of mold-making upper boxes, mold-making lower boxes and double-sided templates rotate to a vertical state, and the molding sand blowing inlet moves upward; the molding sand blowing inlet moves up and down two molding spaces Fill the molding sand inside; the upper and lower extrusion devices enter the upper and lower molding spaces and squeeze the molding sand in the spaces respectively, and a pair of molding upper boxes, molding lower boxes and double-sided templates return to the horizontal state; After the pair of mold-making upper boxes and mold-making lower boxes are separated from the double-sided templates, the double-sided templates are pulled out from the pair of mold-making upper boxes and the mold-making lower boxes; during the above process, if necessary, After the core is set inside the casting mold, the mold-making upper box and the mold-making lower box containing the casting mold are matched with each other; the casting mold is pulled out from the matched pair of mold-making upper box and mold-making lower box.

Owner:SINTOKOGIO LTD

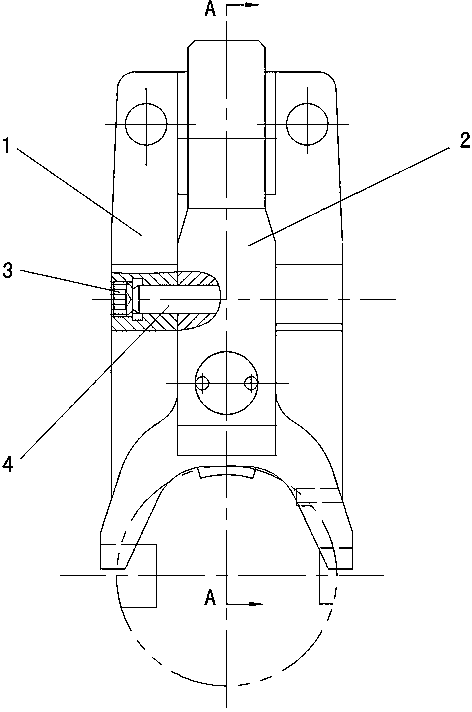

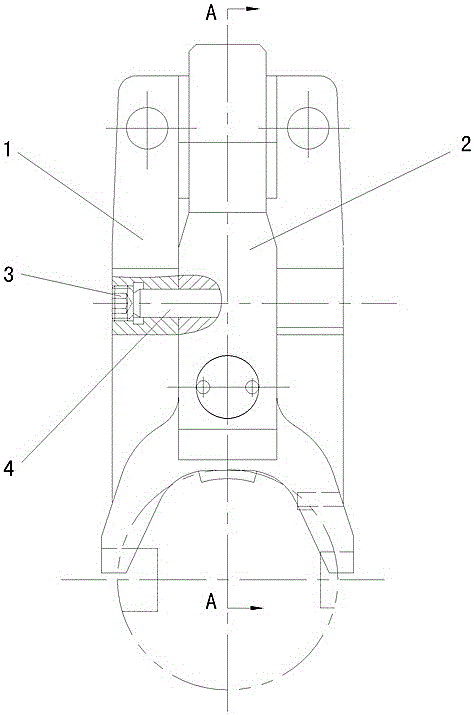

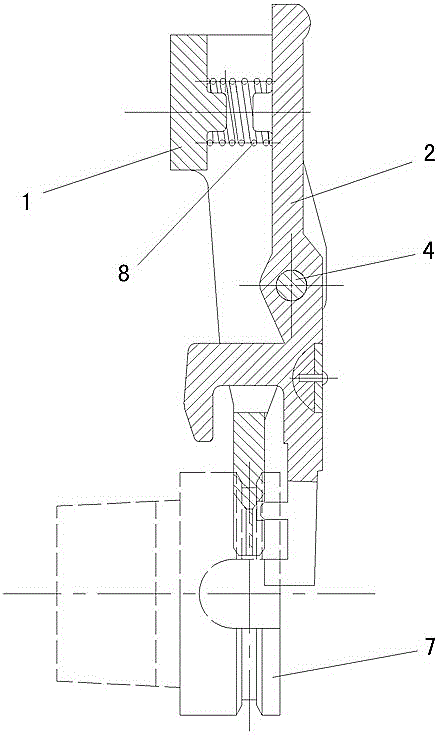

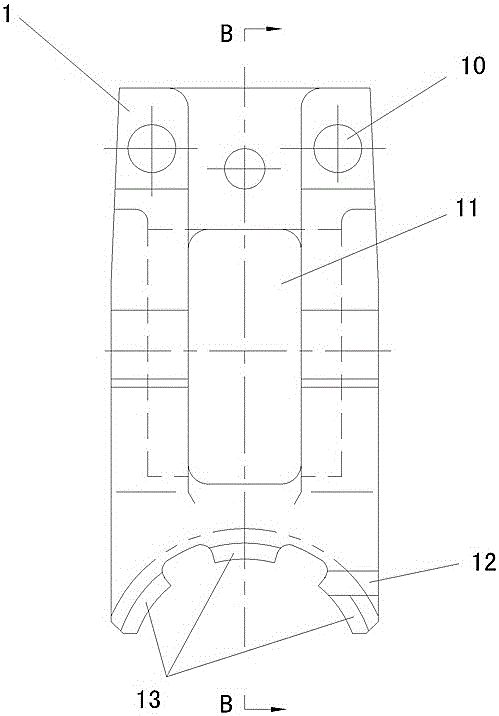

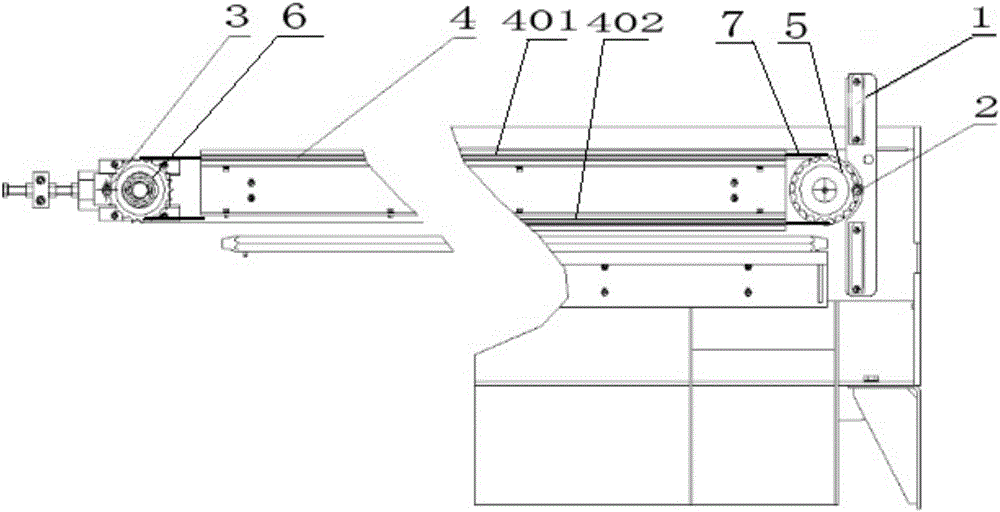

Self-locking cutter quick exchange device

ActiveCN103495895AShort exchange timeReduce auxiliary timePositioning apparatusMetal-working holdersSelf lockingEngineering

The invention provides a self-locking cutter quick exchange device which comprises a fixed claw and a movable claw. The middle of the fixed claw and the middle of the movable claw are in rotatable connection through a pin roll. A spring is arranged between one end of the fixed claw and one end of the movable claw, the other end of the fixed claw is of an arc-shaped fork shape, and a protrusion which is matched with a groove in the outer periphery of a cutter handle is arranged on the inner side of the other end of the fixed claw. The other end of the movable claw is provided with a hanging claw which is matched with a groove in the end face of the cutter handle and an anti-rotating boss which is matched with the an anti-rotating groove which is formed in the end face of the cutter handle, a collision head is arranged on the side face of the movable claw, and the collision head extends to the other side from a center hole in the fixed claw (1). According to the self-locking cutter quick exchange device, the cutter exchange time is short when a cutter is exchanged, the auxiliary time is shortened, the working efficiency is improved, the structure is simple due to few parts, the occupied space is small, and breakdowns can not happen easily.

Owner:通用技术集团大连机床有限责任公司

Method for preparing LiLSX molecular screen

ActiveCN101289196BImprove adsorption capacityAvoid pollutionMolecular-sieve and base-exchange compoundsMolecular sieveIon exchange

The invention relates to a preparation method for a LiLSX molecular sieve, which comprises the steps that LSX zeolite is prepared, LSX is exchanged into KLSX, K2SO4 solution is adopted and KOH solution is used for regulating the PH value to 8.5, a method of displacing for a plurality of times is used with 2 minutes of replacing time for each replacement and the temperature of the solution is about 80 DEG C, exchange liquid after being exchanged a plurality times is used in the next group of the exchange process of K<+>; then a method that is similar to the replacement of K<+> solution is adopted to exchange into NH4LSX, the PH value of the solution is 8.5; then LiOH solution is used for exchanging Li<+> into LiLSX at the temperature of 50 DEG C and air is added to discharging NH3 at the same time; finally, washing, drying, and the like, are carried out and finished products are obtained. The method is characterized by adopting ion exchange in a short time, using substances exchanged circularly and having suitable temperature and PH values of exchange solutions and high utilization ratio of Li, and finally the LiLSX molecular sieve with high degree of crystallinity is obtained.

Owner:LUOYANG JALON MICRO NANO NEW MATERIALS CO LTD

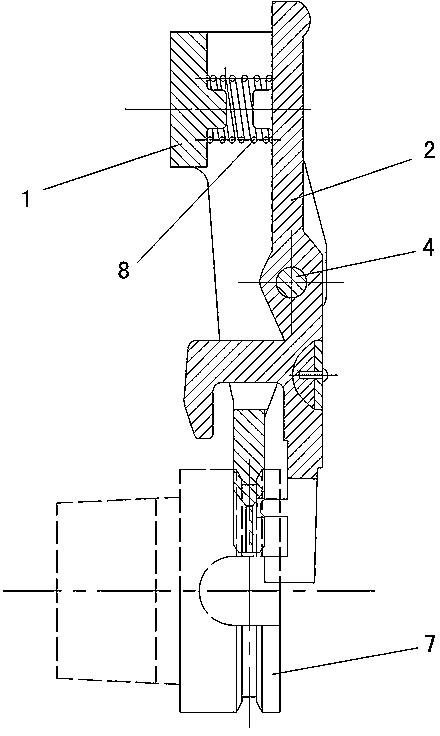

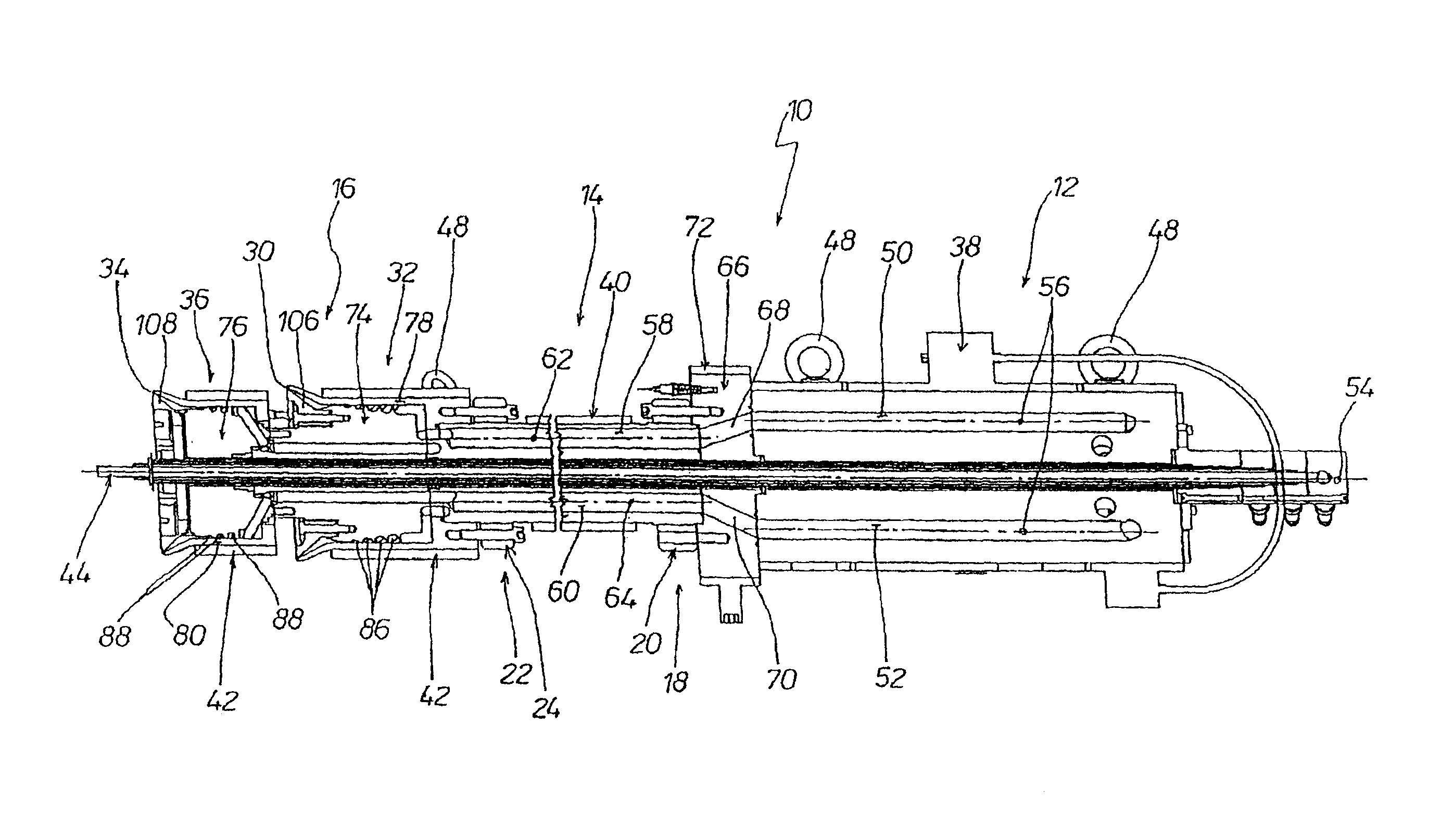

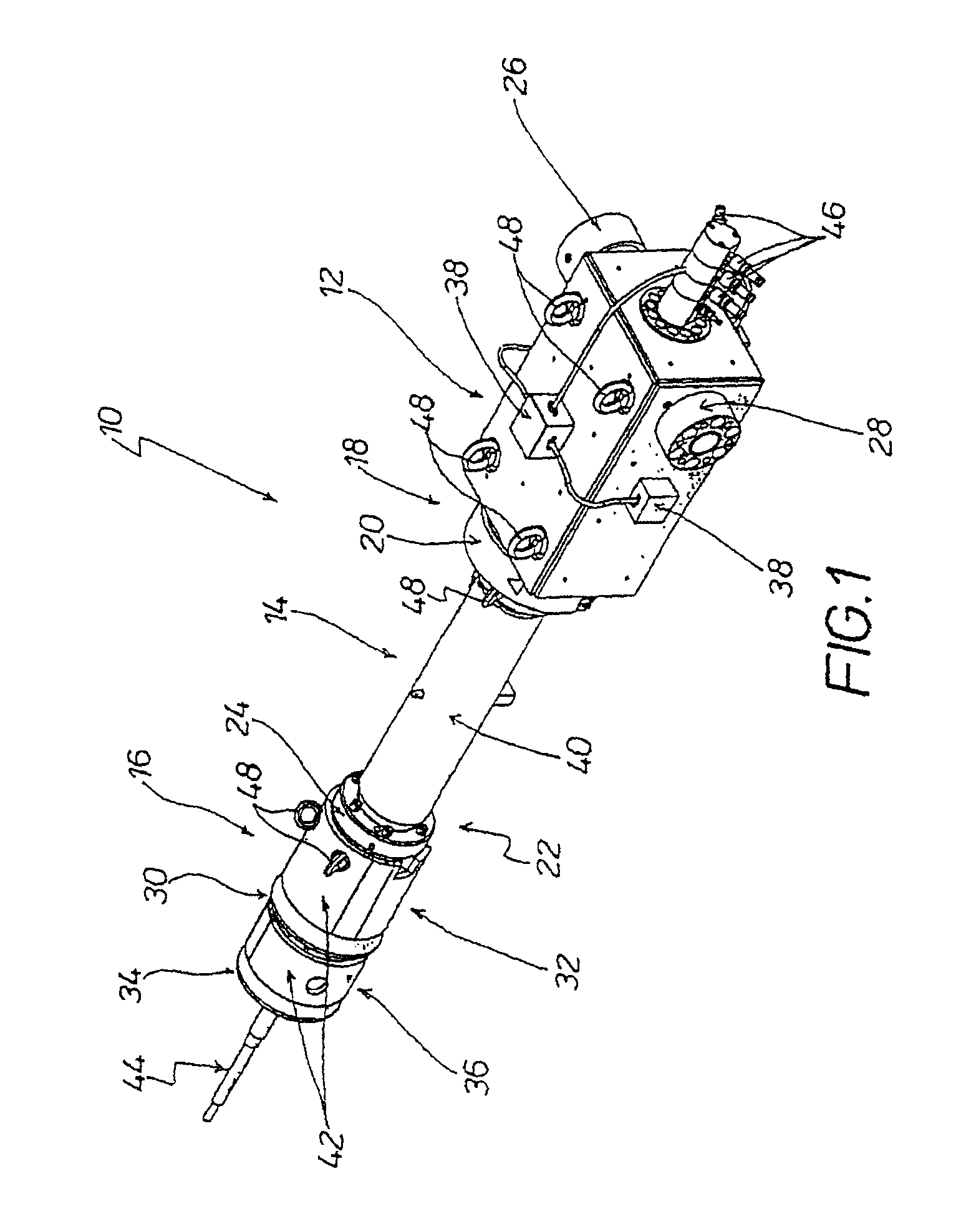

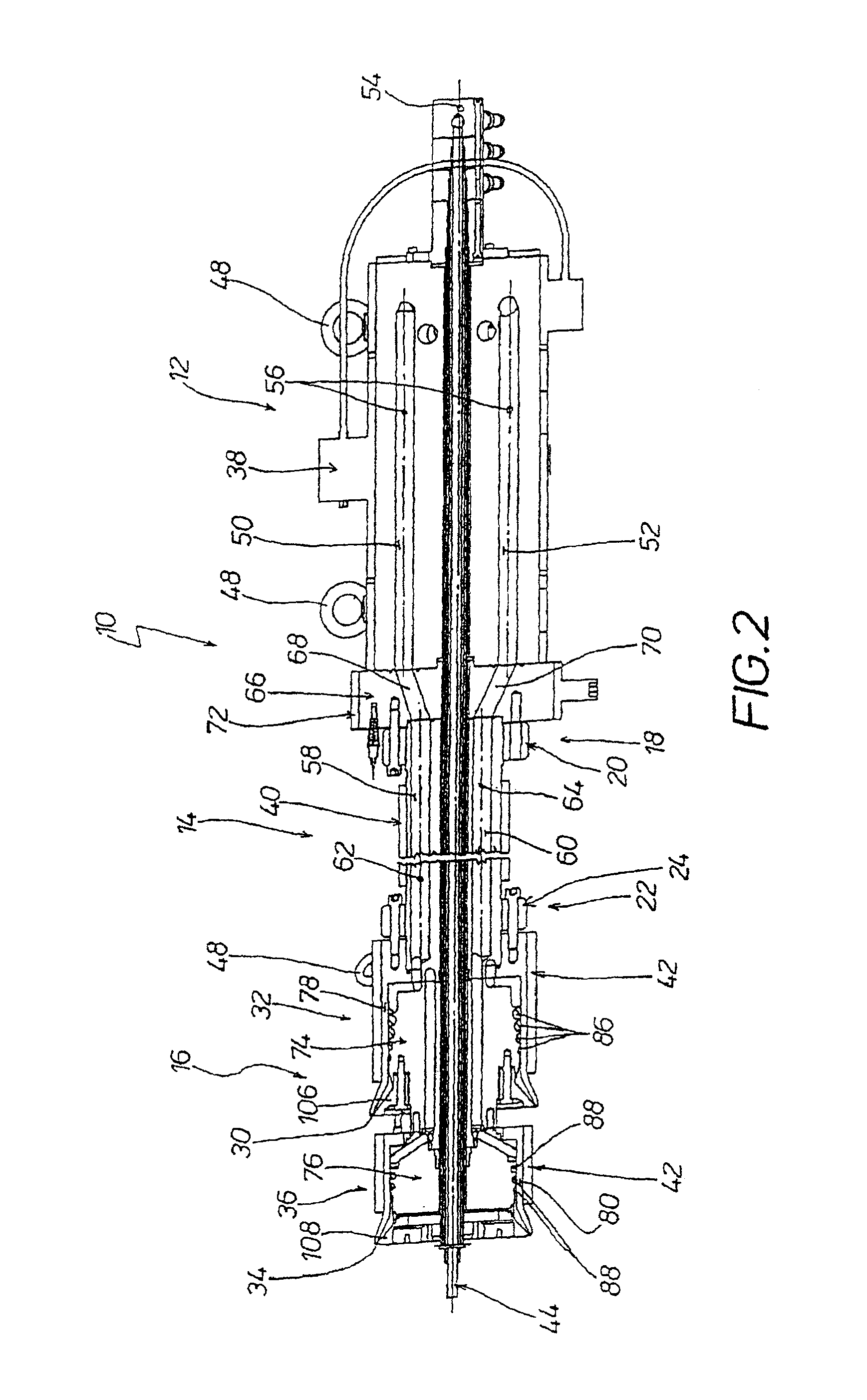

Injection head for a corrugator for the production of plastics pipes

ActiveUS8043082B2Low production costShort exchange timeConfectionerySweetmeatsDistributorBiomedical engineering

An injection head (10) is described for a corrugator which is intended for the production of plastics pipes. The injection head (10) has a main head (12), a nozzle body (14) and a mouthpiece means (16) with at least one mouthpiece (32, 36). The main head (12) is embodied with first channels (50, 52) and the nozzle body (14) is embodied with second channels (58, 60) which are flow-connected to the first channels (50, 52). The / each mouthpiece (32, 36) has a central body (74, 76) and a sleeve body, (78, 80) surrounding said central body. On its lateral surface (82, 84) facing the sleeve body (78, 80), the central body (74, 76) is embodied with wound plastics distributor grooves (86, 88) which are flow-connected by means of connecting portions (114, 120) to a concentric annular groove (112, 116) which is formed on the reverse surface (90, 92) of the central body (74, 76) and into which the second channels (58, 60) of the nozzle body (14) discharge.

Owner:UNICOR

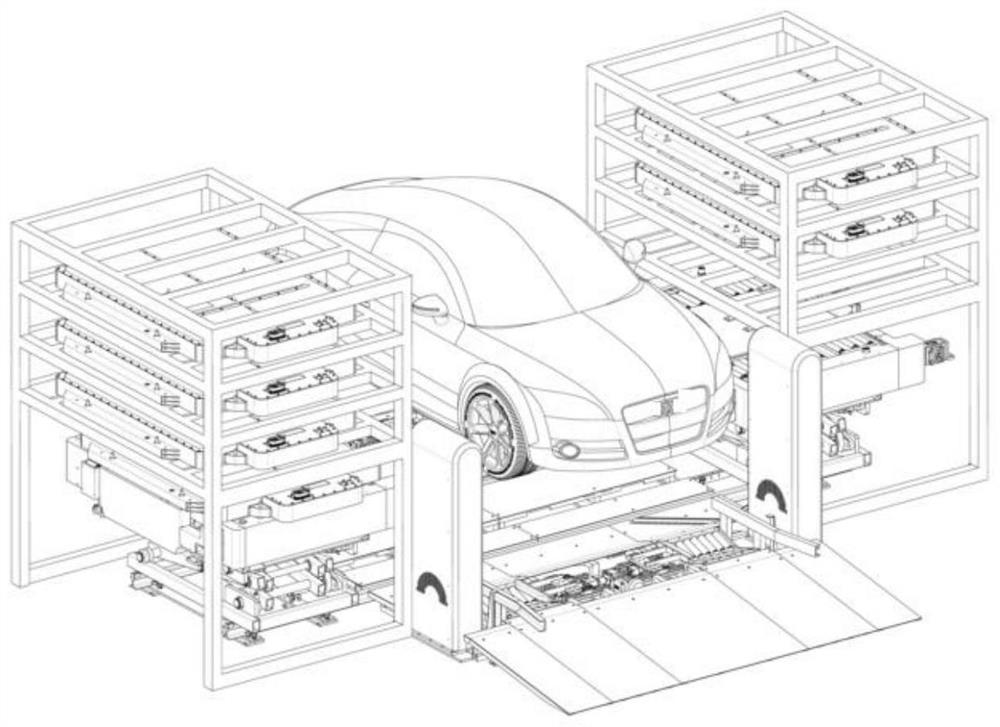

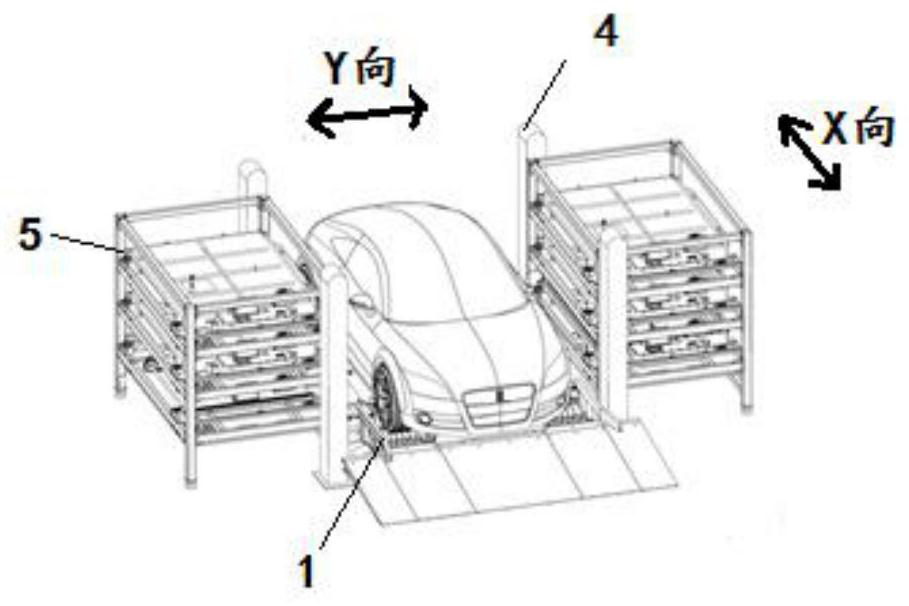

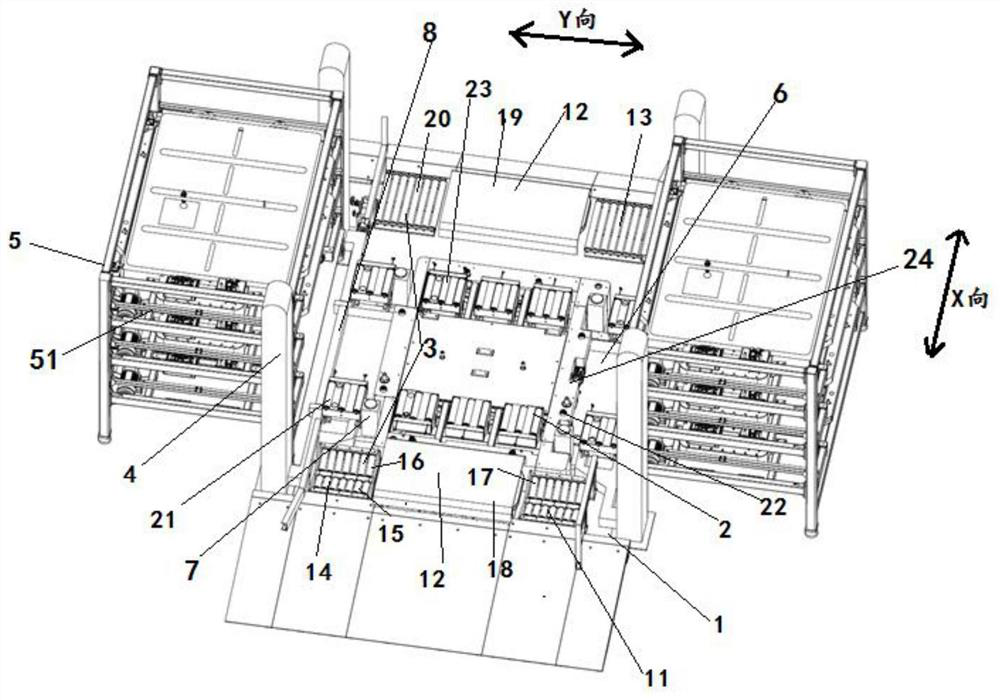

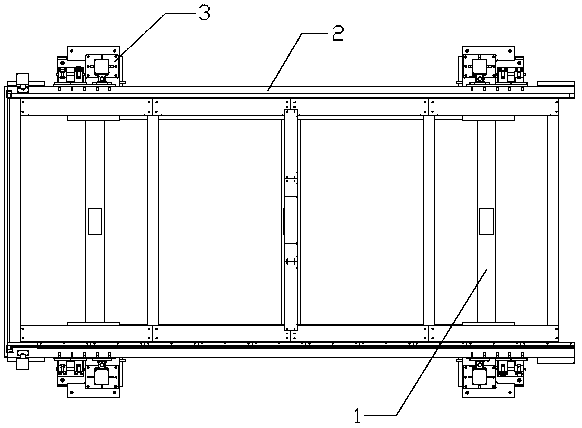

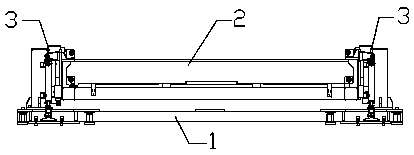

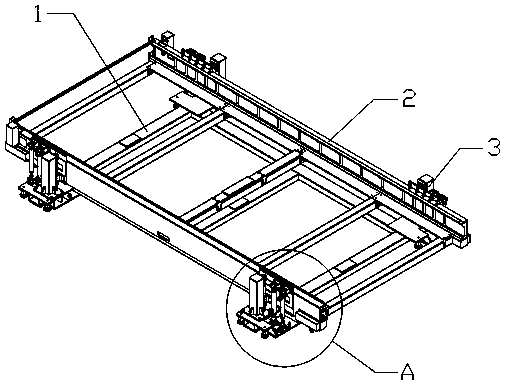

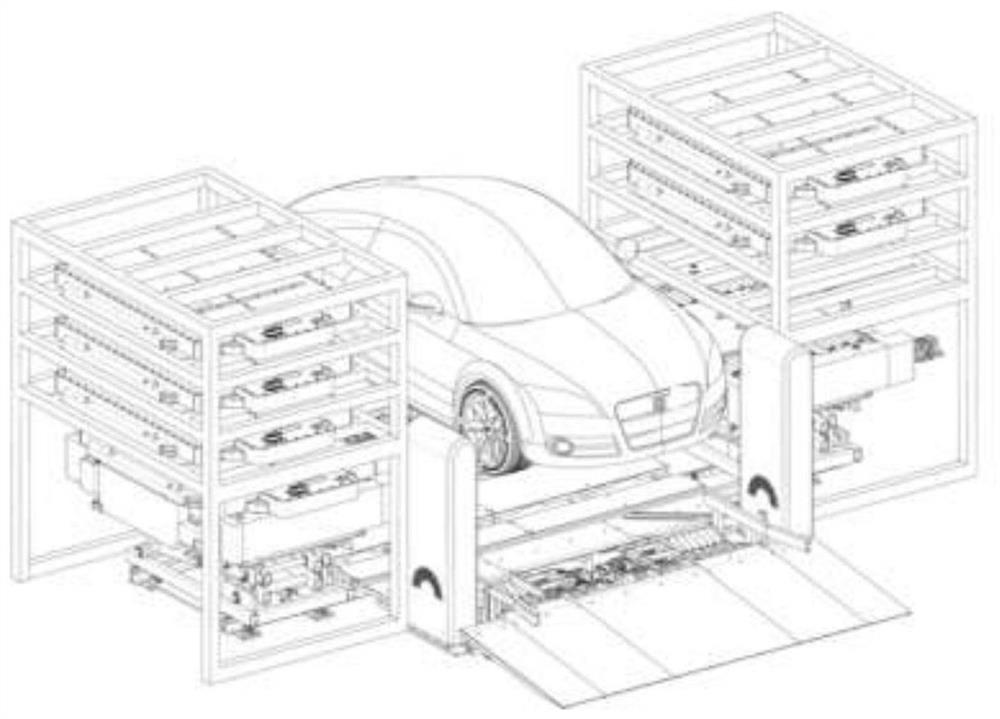

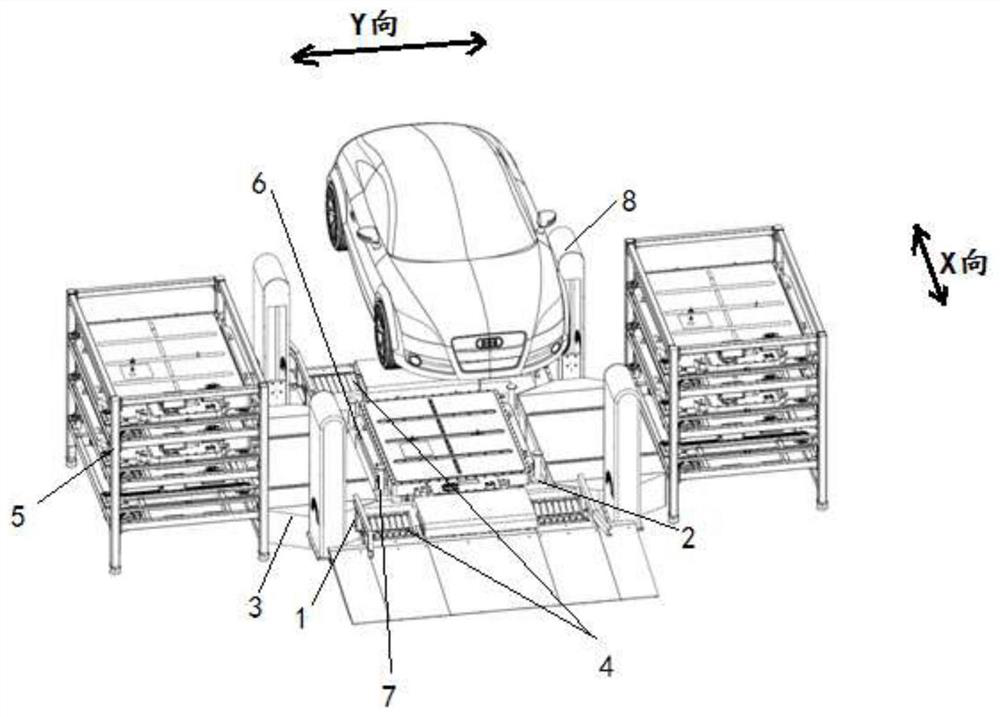

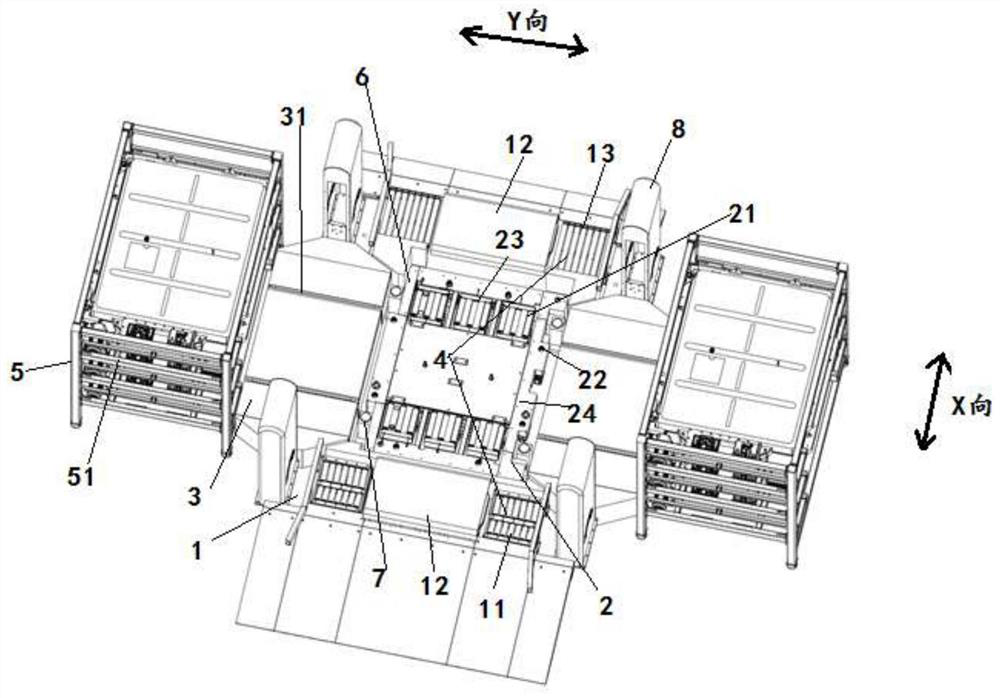

Automatic battery swapping platform and swapping station for electric vehicles

ActiveCN109501753BWidely used valueDrive lessCharging stationsElectric vehicle charging technologyElectrical batteryPower exchange

The invention relates to an automatic battery exchange platform and a battery exchange station for electric vehicles. The battery exchange platform includes a battery exchange mechanism for performing battery exchange operations, including a tightening gun and a battery transmission part. The tightening gun has a first part lower than the battery transmission part. position and the second position higher than the battery transmission part, one of the tightening gun and the battery transmission part can be raised and lowered relative to the other; the battery transmission part is used to transfer the battery pack in the Y direction; the support at both ends of the battery exchange mechanism along the X direction The positioning mechanism is used to support each wheel; the lifting mechanism is connected to the power exchange mechanism and is used to lift the entire power exchange mechanism. The swap station includes a swap platform and battery pack storage devices located on one or both sides of the swap platform along the Y direction. There is no need to lift the vehicle during the battery exchange process, and the overall height of the battery exchange station is controlled; the battery pack can be lifted and stacked without a complicated lifting mechanism, the battery exchange process is simple, the battery pack exchange time is short, and the battery exchange efficiency is high. user experience.

Owner:NIO ANHUI HLDG CO LTD

Laser cutting machine hydraulic lifting working platform

PendingCN110480194AMeet the needs of useLift exchange speed blockLaser beam welding apparatusMarine engineeringLaser cutting

The invention discloses a laser cutting machine hydraulic lifting working platform. The laser cutting machine hydraulic lifting working platform comprises a chassis and a working platform arranged above the chassis; the chassis and the working platform are both of rectangular structures; bases extending outwards are correspondingly arranged in positions, close to the four corners, of the externalside of the chassis; hydraulic lifting devices capable of vertically moving up and down are arranged on the bases; the tops of the hydraulic lifting devices are connected with the working platform; and the four groups of hydraulic lifting devices arranged on the chassis realize oil passage pressure balance by being connected with an external synchronous hydraulic station and drives the working platform to vertically move up and down. By using a hydraulic oil cylinder as a transmission mode, the laser cutting machine hydraulic lifting working platform has the advantages that the lifting exchanging speed is high, the exchanging time is short, the performance is stable, the platform can bear a large-area thick steel plate with larger weight, the use of a large-power laser cutting machine canbe satisfied, the structure is simple, the platform is easy to mount and detach, the later maintenance is simpler, the use cost is reduced, and the production efficiency is enhanced.

Owner:苏州领创先进智能装备有限公司

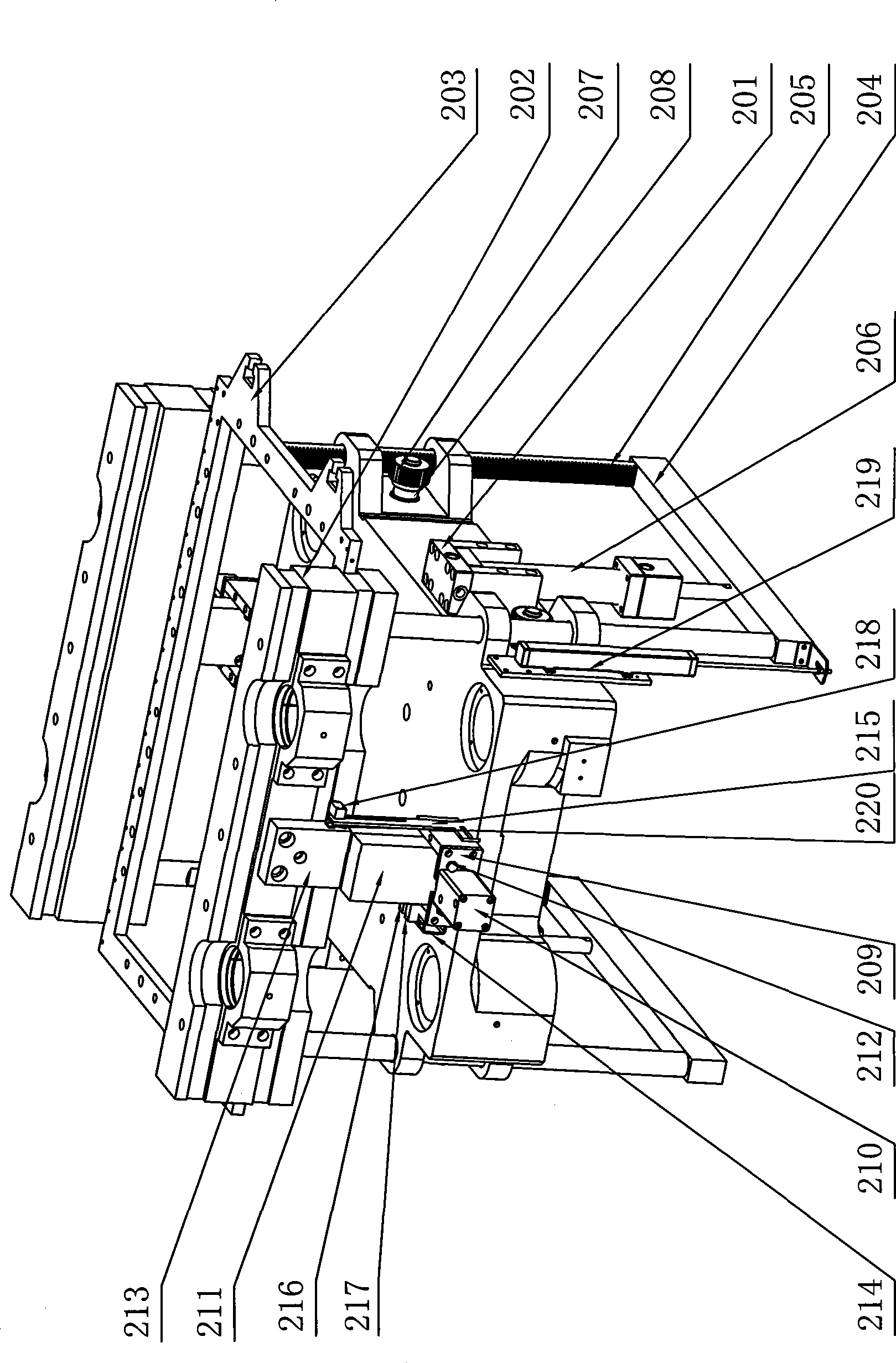

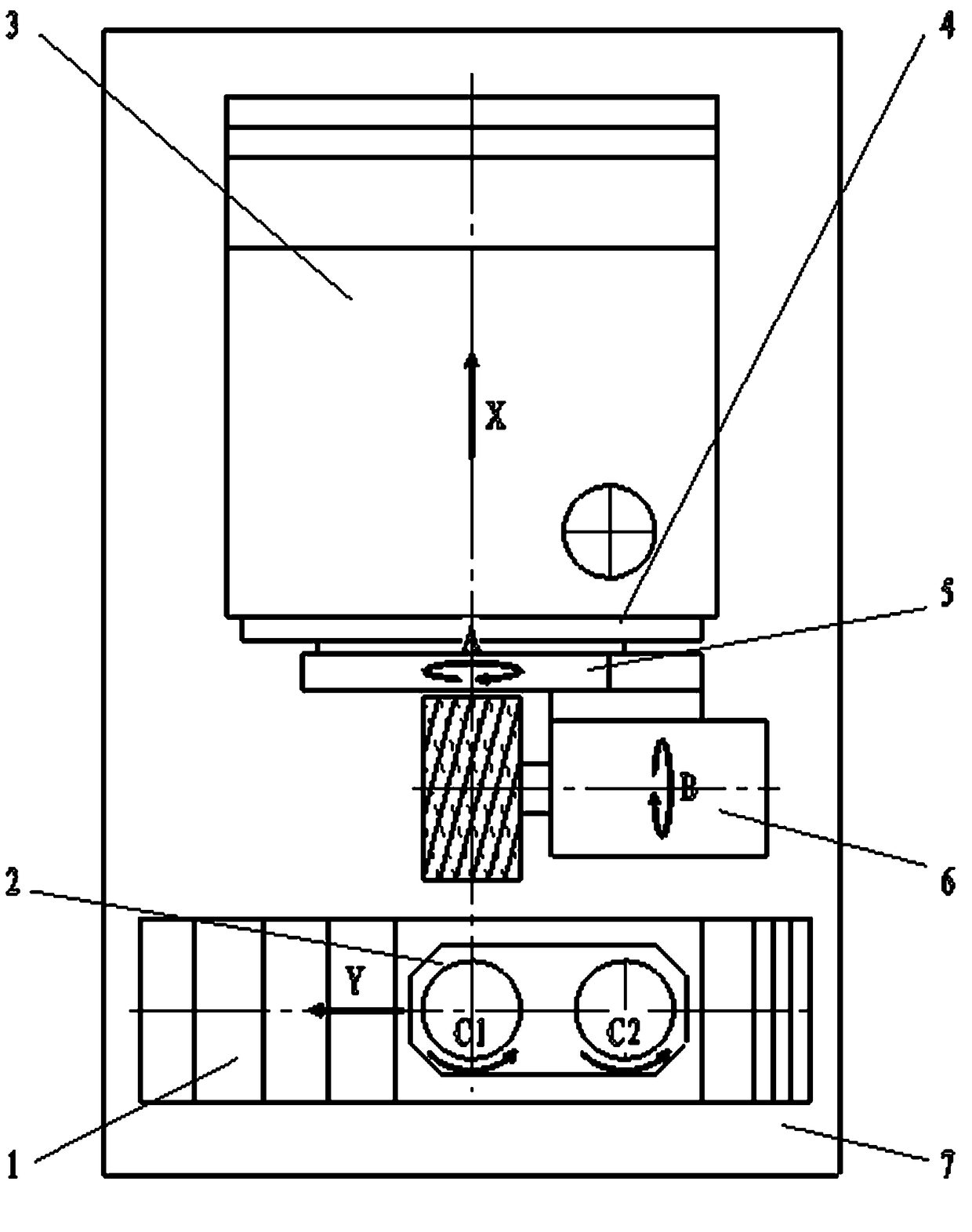

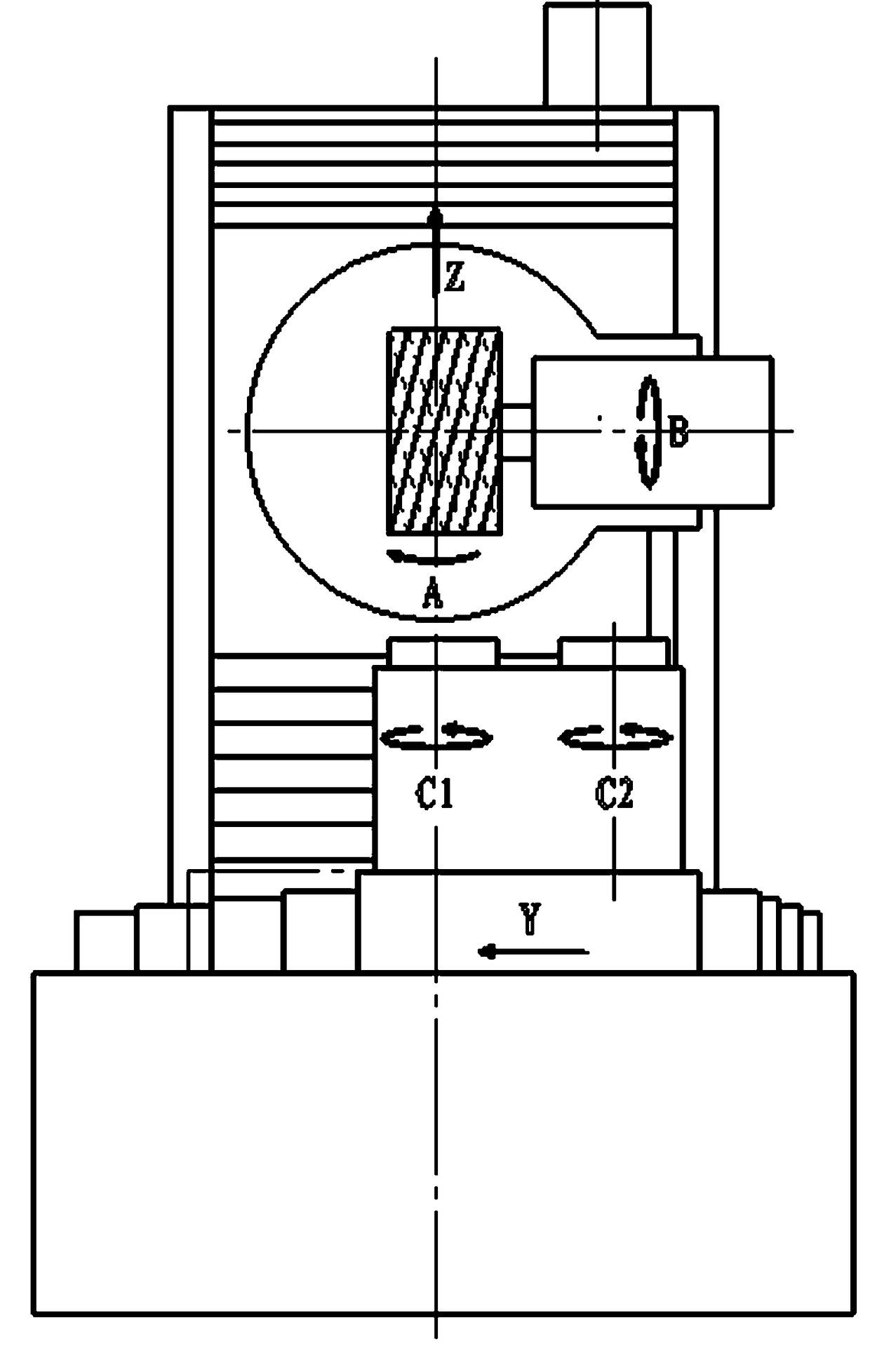

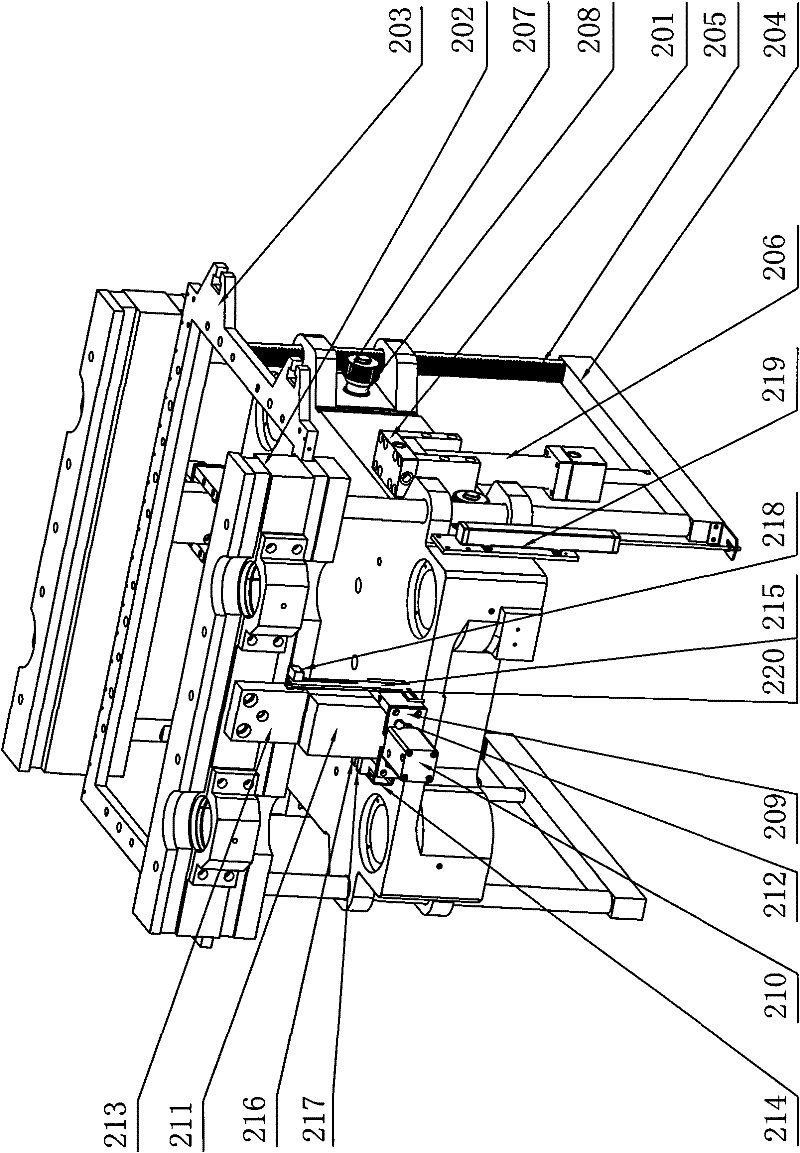

Double-station efficient worm-grinding-wheel computer numerical control gear grinding machine

PendingCN109108391AAvoid the problem of poor rigidity in the movement of tangential serial knivesAvoid the problem of poor motion rigidityWormsGear grindingNumerical control

The invention provides a double-station efficient worm-grinding-wheel computer numerical control gear grinding machine which comprises a moving workbench, double workpiece spindles, a vertical column,a vertical sliding plate box, a spiral disc, a grinding wheel spindle and a machine tool body, wherein the moving workbench is mounted at the front part of the machine tool body through a horizontallinear guiding guide positioned in the left-right direction; the double workpiece spindles are mounted on the moving workbench along the left-right direction of the moving workbench; two rotating axesof the double workpiece spindles are in the perpendicular state; the bottom of the vertical column is mounted at the rear part of the machine tool body through a linear guiding rail positioned in thefront-rear horizontal direction; the vertical sliding plate box is mounted in an inner cavity of the vertical column through a linear guiding rail positioned in the upper-lower perpendicular direction; the spiral disc is mounted at the front part of the vertical sliding plate box through a front-rear horizontal rotating support in the vertical sliding plate box; the grinding wheel spindle is mounted at the front part of the spiral disc; and the rotating axis of the grinding disc spindle and that of the spiral disc intersect perpendicularly. According to the double-station efficient worm-grinding-wheel computer numerical control gear grinding machine provided by the invention, the double workpiece spindles are driven through the linear moving workbench to be exchanged; the overlap betweenthe grinding time and the auxiliary time for loading and unloading is achieved; and the workpiece spindle exchange time is short and the repeated positioning precision is high.

Owner:NANJING INST OF TECH

Self-locking tool quick change device

ActiveCN103495895BShort exchange timeReduce auxiliary timePositioning apparatusMetal-working holdersEngineeringSelf locking

The invention provides a self-locking cutter quick exchange device which comprises a fixed claw and a movable claw. The middle of the fixed claw and the middle of the movable claw are in rotatable connection through a pin roll. A spring is arranged between one end of the fixed claw and one end of the movable claw, the other end of the fixed claw is of an arc-shaped fork shape, and a protrusion which is matched with a groove in the outer periphery of a cutter handle is arranged on the inner side of the other end of the fixed claw. The other end of the movable claw is provided with a hanging claw which is matched with a groove in the end face of the cutter handle and an anti-rotating boss which is matched with the an anti-rotating groove which is formed in the end face of the cutter handle, a collision head is arranged on the side face of the movable claw, and the collision head extends to the other side from a center hole in the fixed claw (1). According to the self-locking cutter quick exchange device, the cutter exchange time is short when a cutter is exchanged, the auxiliary time is shortened, the working efficiency is improved, the structure is simple due to few parts, the occupied space is small, and breakdowns can not happen easily.

Owner:通用技术集团大连机床有限责任公司

Automatic battery swapping platform and swapping station for electric vehicles

ActiveCN109501755BWidely used valueDrive lessCharging stationsElectric propulsion mountingElectrical batteryPower exchange

The invention relates to an automatic power exchange platform and a power exchange station for an electric vehicle, including a power exchange mechanism, a battery pack transmission mechanism and a support and positioning mechanism; the power exchange mechanism is used for performing power exchange operations, including a tightening gun and a battery transmission part, and the tightening gun It has a first position lower than the battery transmission part and a second position higher than the battery transmission part; the battery pack transmission mechanism is arranged at at least one end of the power exchange mechanism along the Y direction; the support positioning mechanism is located at both ends of the power exchange mechanism along the X direction. The automatic power exchange station includes a power exchange platform and a battery pack storage device located on one or both sides of the power exchange platform along the Y direction. There is no need to lift the vehicle during the power exchange process, which saves the high-power motor drive for vehicle lifting and controls the overall height of the power exchange station; the battery pack can be lifted and stacked without a complex lifting mechanism, and the power exchange process is simple. The battery pack exchange time is short and the power exchange efficiency is high, which improves the user experience.

Owner:NIO ANHUI HLDG CO LTD

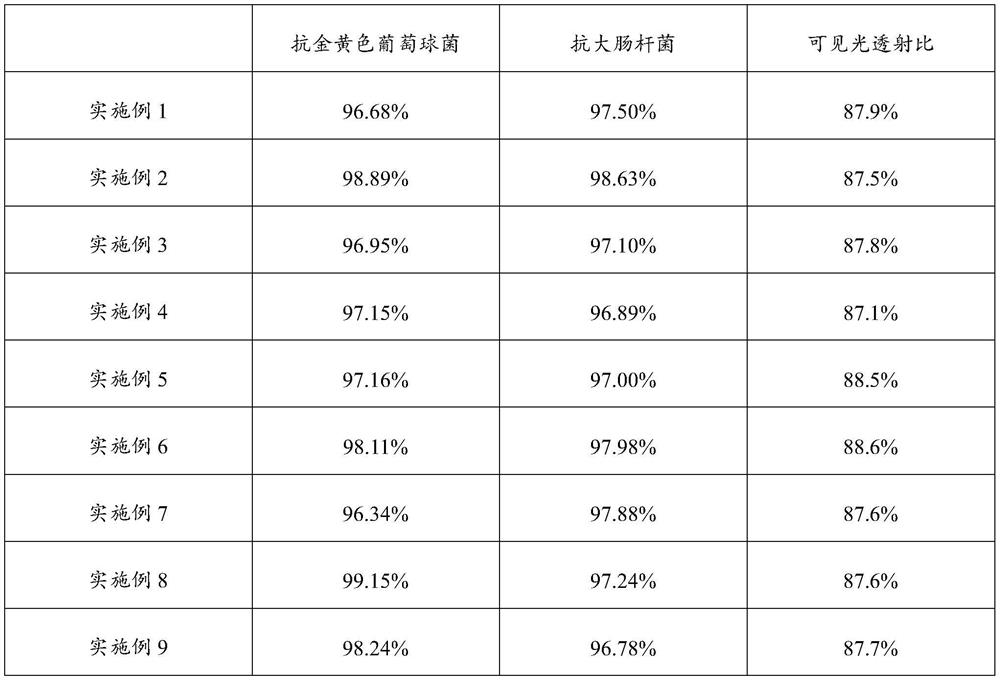

A kind of preparation method of antibacterial glass and antibacterial vacuum glass

ActiveCN110357455BImprove performanceGood light transmissionGlass tempering apparatusPhysical chemistryIon exchange

The invention belongs to the technical field of glass preparation, and in particular relates to a preparation method of antibacterial glass and antibacterial vacuum glass. The preparation method of the antibacterial glass comprises the following steps of performing one-step ion exchange on the glass with a salt solution or melt containing silver and ferrous ions, and introducing antibacterial ions into the glass body to obtain the antibacterial glass. The invention realizes the exchange of antibacterial ions and sodium and potassium ions inside the glass through a one-step ion exchange method, and introduces antibacterial ions into the glass body, the method is simple and effective, and the cost is saved. By introducing ferrous ions in the ion exchange process, the oxidation of antibacterial ions can be effectively inhibited, the concentration of antibacterial ions can be effectively increased, and the decrease of light transmittance of glass can be avoided, which is beneficial to the improvement of antibacterial glass performance and light transmission performance.

Owner:CHINA BUILDING MATERIALS ACAD

Novel ion-exchange material, its preparation and application

InactiveCN100368090CStrong ion exchangeSynthetic method is fastOrganic anion exchangersInorganic anion exchangersPyrazinePhysical chemistry

This invention relates to a new ion exchange material, in addition to its preparing and uses, which belongs to the mineral-organic hybridization function molecular material and synthetic technology. The material is a coordinated polymer having the same three-dimensional opening cage, which can prevent the major cavity structure changing with the anion. The material is based on double piperazidine bridge organic ligand L with oxdiazole ring and Ag1 mineral metal salt, and its general formula is {[Ag(L)]X*solution}n, wherein the molecular formula of L is: C10H6N6O, and X is AsF6-,CF3SO3-, or SbF6- anion.

Owner:TIANJIN NORMAL UNIVERSITY

Parallel non-stop high-speed rail trains entering the station

ActiveCN109131422BShort exchange timeImprove efficiencyRailway auxillary equipmentButt jointEngineering

A parallel access non-stopping high-speed train includes a running track, a running train, an anti-collision track, an electronically-controlled locking door, a platform track, a platform train, an anti-collision pulley, an electronically-controlled flap, an intelligent controller and a waiting platform., wherein an anti-collision pulley and an anti-collision track are arranged on the upper end ofthe running train and the platform train, and the anti-collision pulley slides on the anti-collision track during the parallel butt joint or separation of the two trains, so that a stable distance of2cm is maintained between the running train and the platform train, and the two trains are prevented from colliding and rubbing each other; when the two trains are butted together, the intelligent controller adjusts the speed of the train to synchronize the two trains, and the electronically controlled locking door of the running train penetrates into the electronically controlled valve of the train on the platform to mechanically lock the two trains into an integrated double train. The electronically controlled locking door acts as a windshield to reduce the influence of the outdoor air flowon the indoor of the double trains in high-speed operation. When boarding and disembarking passengers are exchanged, the front and rear doors of the integrated twin trains are fully opened, which canmeet the requirements of larger passenger flow.

Owner:临沭县济才人力资源服务有限公司

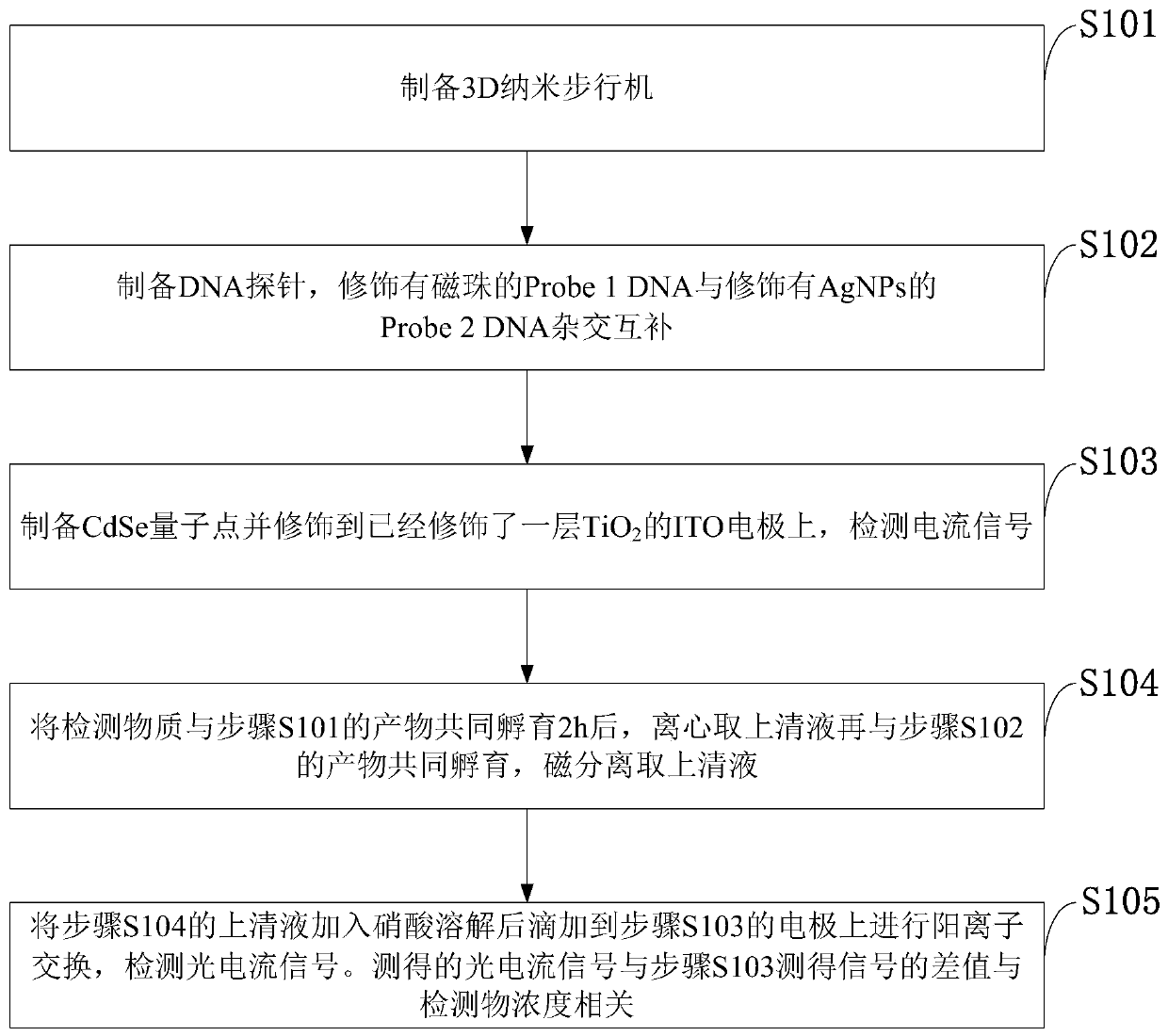

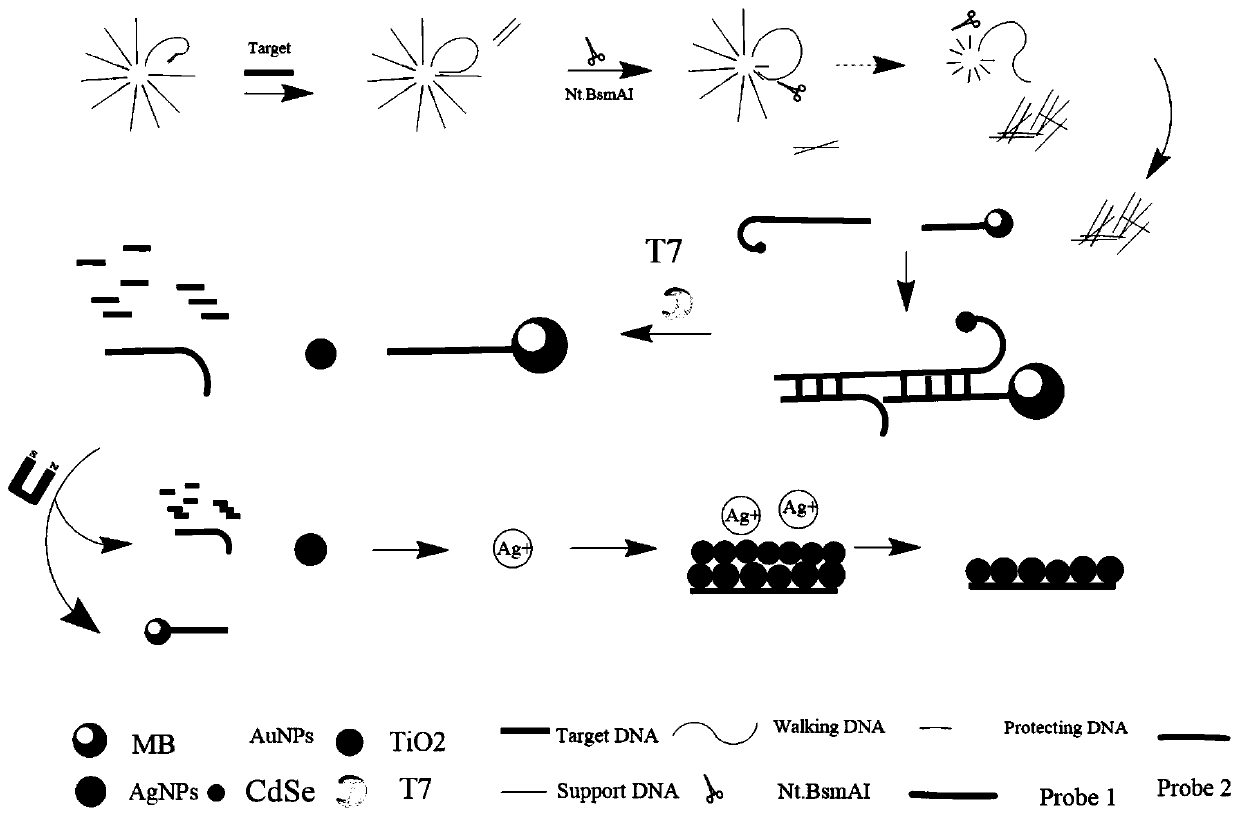

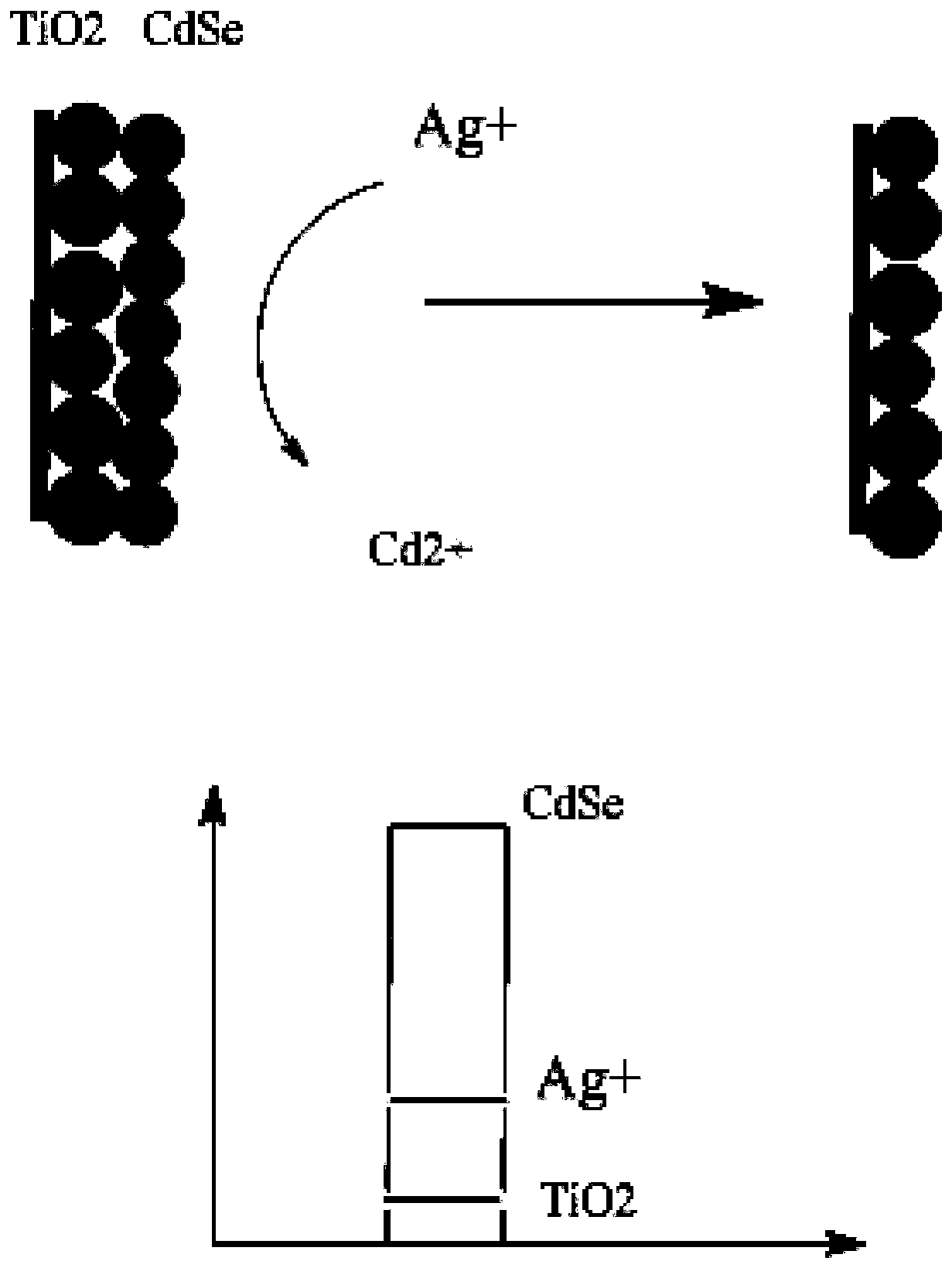

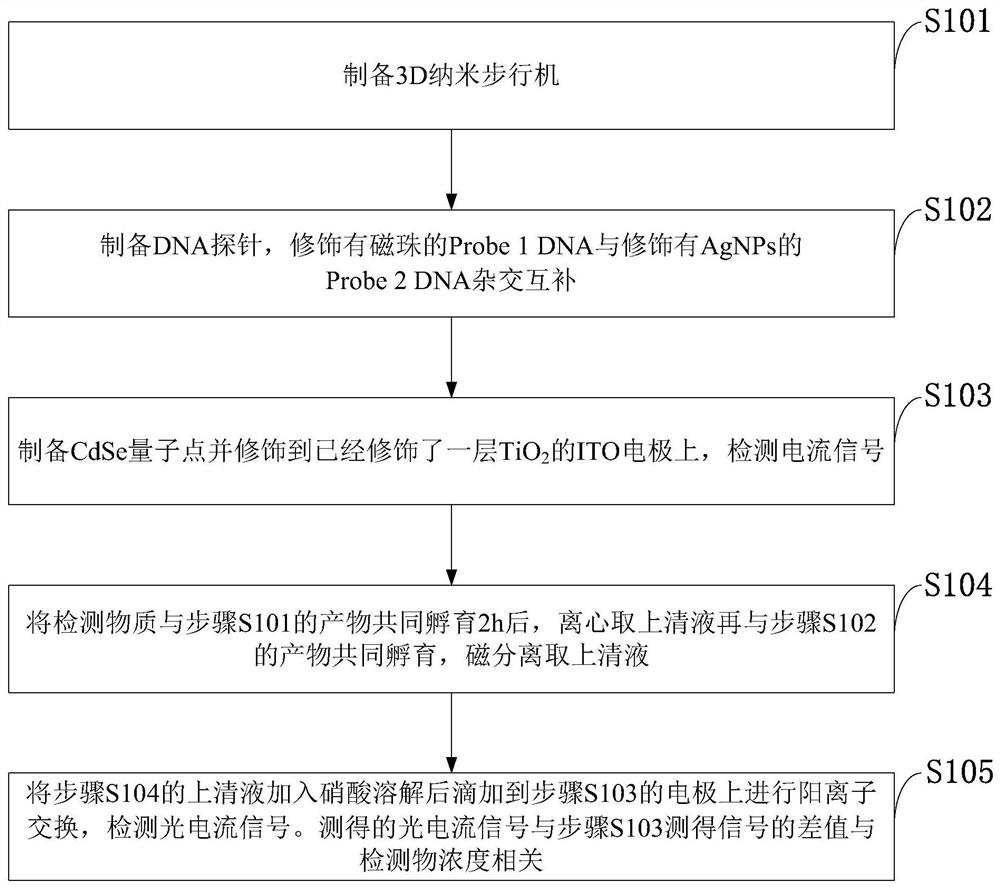

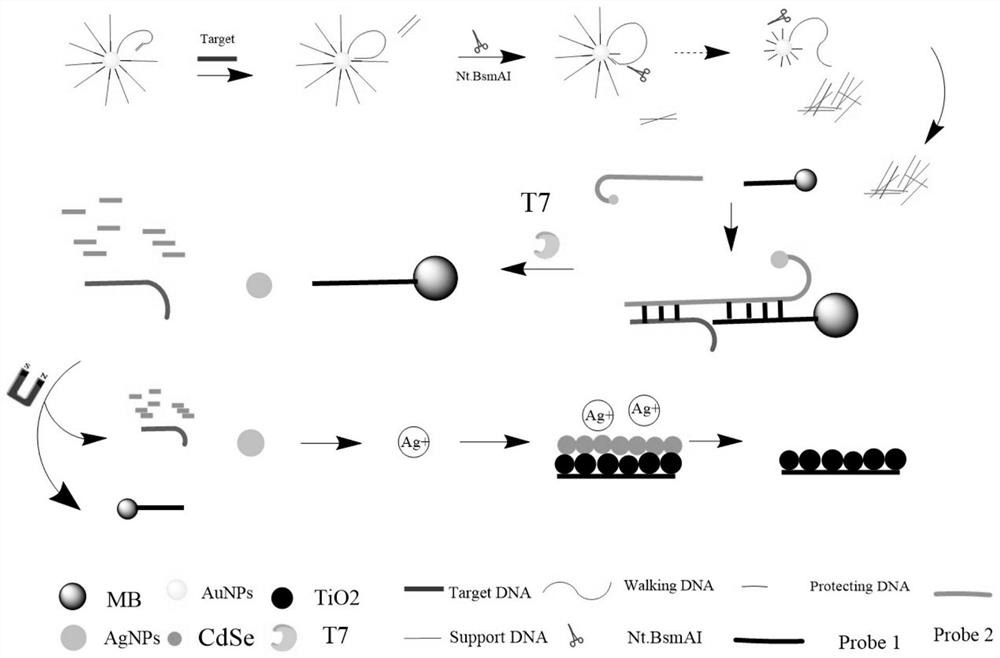

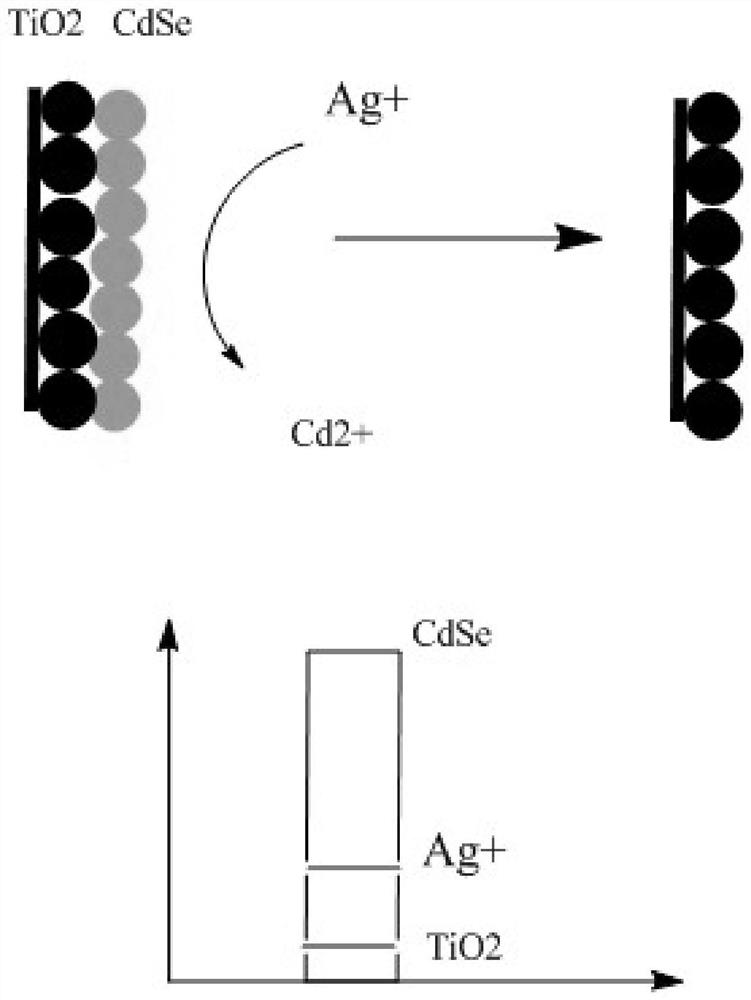

Method for detecting nucleic acid molecules based on cyclic amplification and cation exchange

ActiveCN110320258ARealize detectionPhotoelectric signal reductionMicrobiological testing/measurementBiological testingMagnetic beadAbsorbed energy

The invention belongs to the technical field of nucleic acid molecule detection, and discloses a method for detecting nucleic acid molecules based on cyclic amplification and cation exchange. The method comprises the following steps that a 3D nanometer walking machine is adopted to identify miRNA141 and carry out shearing amplification, magnetic beads and a shearing enzyme circulation technology are combined to release silver nanoparticles, the nanoparticles are converted to ions by an acid, cation exchange is performed with a photoelectric material CdSe, so that the CdSe photoelectric signalis reduced, and the detection of the miRNA141 is realized. The material with photoelectrochemical activity of the invention has the advantages that under the action of light, the outer electrons absorb energy to generate transitions to transfer charge, the electrode material is modified; and the material with photoelectrochemical activity can be combined with DNA, antibody, nano-gold and other substances, the application range of a photoelectrochemical sensor is greatly enriched, and the material with photoelectrochemical activity can also be combined with PCR, enzyme-linked reaction, cyclic amplification and other methods to improve the sensitivity of detection.

Owner:QINGDAO UNIV OF SCI & TECH

Low cost method for preparing SiO2 aerogel micro-sphere

This invention discloses a method for preparing SiO2 aerogel micro-balls with low cost. Low price sodium silicate is used as raw material to produce silicate with pH=2-3 by using ion-exchange, adding catalyst, then being dropped into a vessel containing oil, and hydrophobic matter in the botton. The silicate drops from ball shape due to the surface tension in oil. The drops fall onto the bottom with hydrophobic matter, keep also the ball shape, and stay for a certain time to obtain aquogel micro-balls, which are then separated from oil and water washed, solvent-exchanged by ethanol to obtain alcogel micro-ball; finally, the later are dried to obtain millimeter grade aerogel of SiO2. The advantages are: simple process, achieving commercial production, low cost, able to be recovery of the oil, the product is expected to be used as thermal insulation material or in catalyst field.

Owner:UNIV OF SCI & TECH BEIJING

Multi-station framework switching structure of injection machine

InactiveCN101462347BAccurate docking positioningAvoid the possibility of inaccurate alignmentButt jointInjection molding machine

The invention belongs to an injector multiple-station mold plate exchange structure, which comprises a moving mold component and a hanging mold component, wherein the moving mold component comprises a moving mold bracket and a moving mold seat positioned on the moving mold bracket. A mold plate frame used for supporting a lower mold plate is arranged on the moving mold seat and a supporting plateused for the horizontal displacement of the lower mold plate and the mold plate frame is also connected to the mold plate frame. A moving mold seat lifting device capable of driving the moving mold seat to move up and down, a mold plate frame exchange device and a moving mold seat positioning device are arranged on the moving mold bracket. The hanging mold component comprises a static mold plate and a dynamic mold plate, wherein a hanging mold seat used for supporting the mold plate frame is arranged between the still mold plate and the dynamic mold plate. The mold plate frame which can be exchanged with the mold plate frame on the dynamic mold seat is arranged on the hanging mold seat and a hanging mold seat lifting device, a horizontal moving device making the hanging mold seat move back and forth and a hanging mold seat positioning device are arranged below the mold plate frame. The mold plate exchange structure has the advantages of compact structure, high butt joint precision, precise and stable repeated butt joint and positioning precision and safe and reliable use.

Owner:DEKEMO HUADA MECHANICAL DONGGUAN +1

A method for the detection of nucleic acid molecules based on cyclic amplification and cation exchange

ActiveCN110320258BRealize detectionPhotoelectric signal reductionMicrobiological testing/measurementBiological testingNanoparti clesPhotochemistry

Owner:QINGDAO UNIV OF SCI & TECH

Exchange device for elevated worktable of laser cutting machine

InactiveCN106181081AAchieve liftingSimple structureLaser beam welding apparatusEngineeringLaser cutting

The invention belongs to the field of laser machining equipment and particularly relates to an exchange device for an elevated worktable of a laser cutting machine. The exchange device comprises a fixed guide block and a slideway assembly, wherein one end of the slideway assembly is fixedly connected to the fixed guide block, a first chain wheel is arranged on one side of the fixed guide block and is movably connected to the slideway assembly, one end of the slideway assembly is movably connected to a second chain wheel, chains are connected to the first chain wheel and the second chain wheel, and two ends of the chains are fixedly connected to a lower traction guide ball and an upper traction guide ball, respectively. According to the exchange device for the elevated worktable of the laser cutting machine provided by the invention, the worktable which rises and falls is guided by the fixed guide block and the traction guide balls simultaneously; the worktable dragged by the traction guide balls displaces left and right to alternately arrive the working position, so that the worktable rises and falls. The moving distance is precisely controlled by a servo motor and a coder, and meanwhile, accelerating and decelerating regions are reasonably arranged at the same time. The exchange device is simple in structure and short in exchange time, and the work efficiency of the equipment is greatly improved.

Owner:JIANGSU YAWEI MACHINE TOOL

Method and device for forming flaskless cope and drag, and method of replacing matchplate

A method and device capable of efficiently forming a high-quality flaskless cope and drag. A matchplate is held by a cope and drag as a set, the cope and drag being in a horizontal state and each having a sand blowing nozzle in the side wall. Upper and lower squeeze means are respectively inserted in matchplate-less openings in the cope and drag to define two upper and lower cavities. The cope and drag and the matchplate are set in a vertical state, and at the same time the sand blowing nozzles are moved upward. Molding sand is blown from the sand blowing nozzles into the two upper and lower forming cavities to fill the cavities. While the cope and drag and the matchplate being returned to a horizontal state, the upper and lower squeeze means are further advanced, and the molding sand in the two upper and lower forming cavities are individually squeezed. The cope and drag containing the mold are separated from the matchplate, and then the matchplate is removed from between the cope and drag. A core is set, when required, in the mold previously formed during the steps above, and then the mold is removed from the cope and drag containing the mold.

Owner:SINTOKOGIO LTD

Coordination polymer type ion exchange material, preparation and application thereof

InactiveCN101220023BStrong ion exchangeSynthetic method is fastOrganic chemistryOrganic anion exchangersPyrazineOpen framework

The invention discloses a coordination polymer ion exchange material, a preparation and the application thereof, belonging to the inorganic-organic hybrid functional molecular materials and the synthetic technique, which relates to a group of coordination polymer with a same 3-D open framework and preparation. The invention solves the problem that the exchange process of the ion is not easy to becarried out due to that a cavity structure of a body of the ion exchange material is easily changed with the change of an anion, and the problem of difficult post-treatment. The material of the invention is the material based on a novel organic coordination L of double-pyrazine containing an oxadiazole ring and an Ag inorganic metal salt; wherein, a molecular formula of L is C10H6N6O, and an anionof the Ag inorganic metal salt is AsF6<->, CF3SO3<->or SbF6<->. The material has the advantages of good selected ion-exchange performance, simple synthetic techniques and equipment, short reaction time, easy post-treatment, higher yield, simple and easy exchange process; thereby having the possibility for pushing the materials from the laboratory to practical application.

Owner:TIANJIN NORMAL UNIVERSITY

Method for rapid preparation of SiO2 aerogel microsphere

A method for rapidly preparing SiO2 airgel microspheres belongs to the field of inorganic non-metallic materials, in particular to a method for rapidly preparing SiO2 airgel microspheres. The invention uses water glass as a raw material to obtain silicic acid with a pH of 2-3 through ion exchange, adds an alkaline catalyst, and then adds it into hydrophobic oil and stirs it at the same time. The silicic acid is stirred and sheared into tiny droplets, which are suspended in the oil in a spherical shape due to the surface tension until the gel forms gel microspheres, then the stirring is stopped, and then the oil is separated from the microspheres and washed with water to obtain Hydrogel microspheres. Alcohol gel microspheres are obtained by immersing the hydrogel microspheres in ethanol solution and absolute ethanol successively for solvent exchange, and airgel microspheres with a particle diameter of millimeter or micron can be obtained after drying. The invention has the advantages of low cost, simple and easy-to-control process, easy realization of large-scale production, good product quality and wide application prospects in the fields of heat insulation, catalysis and the like.

Owner:UNIV OF SCI & TECH BEIJING

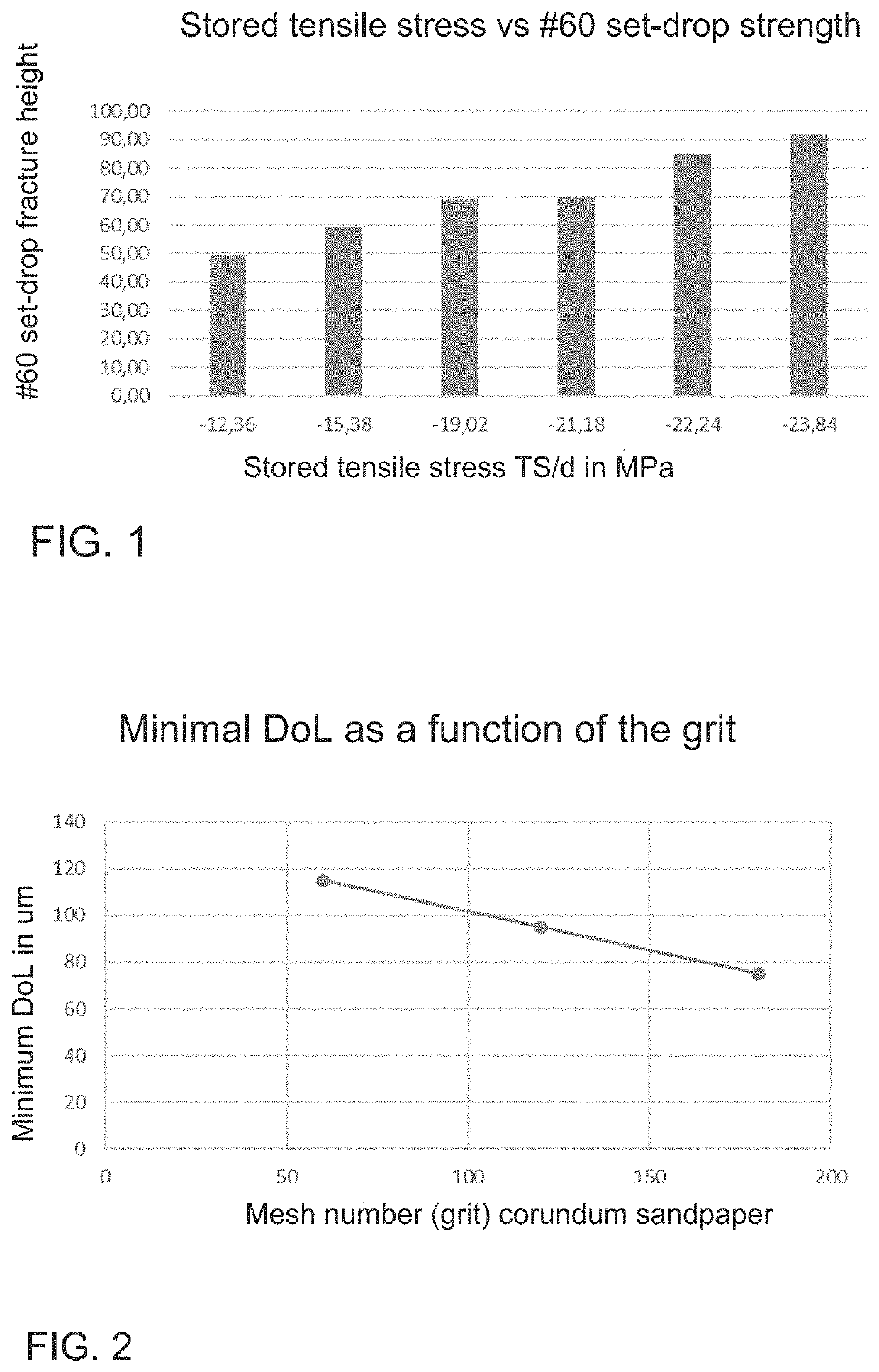

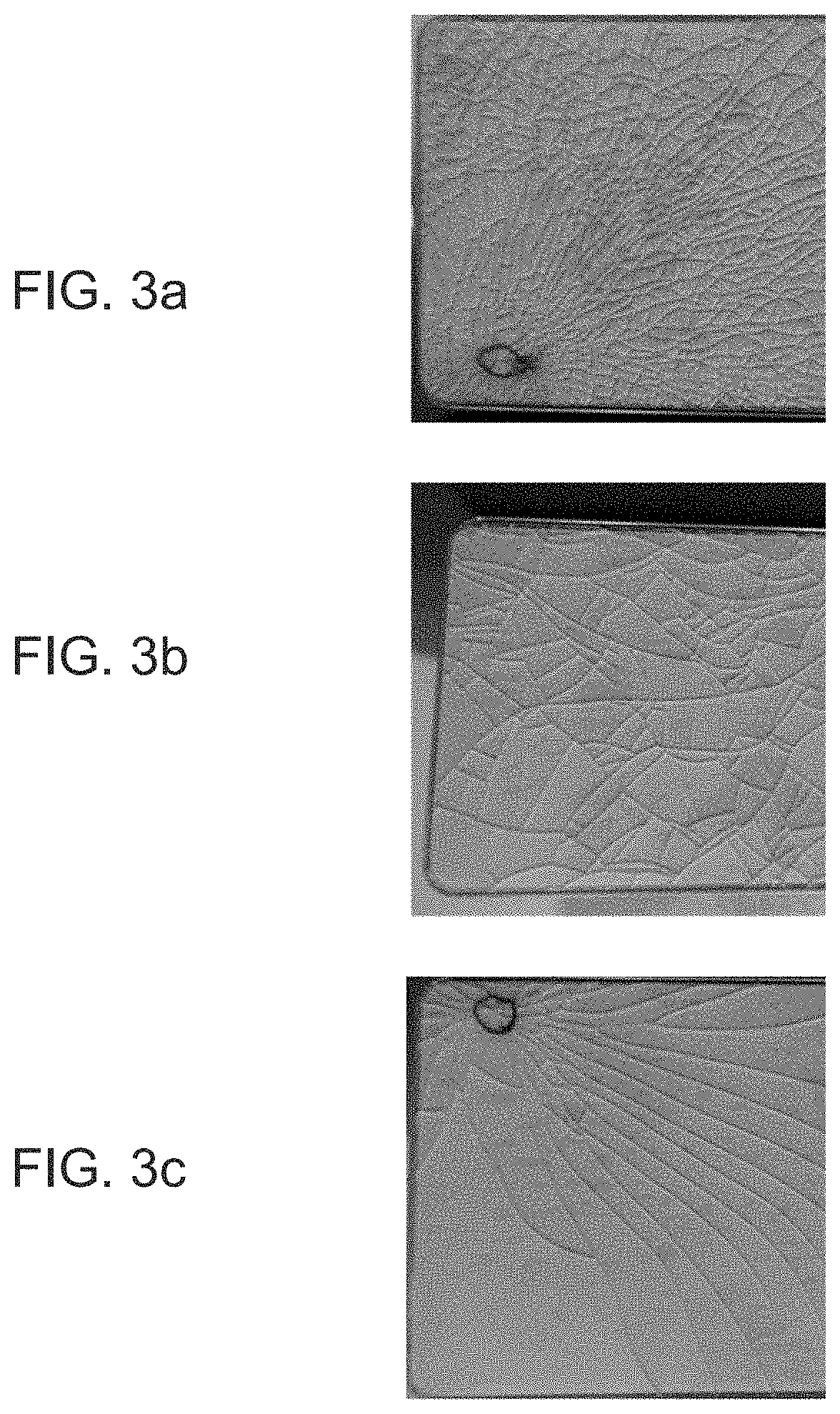

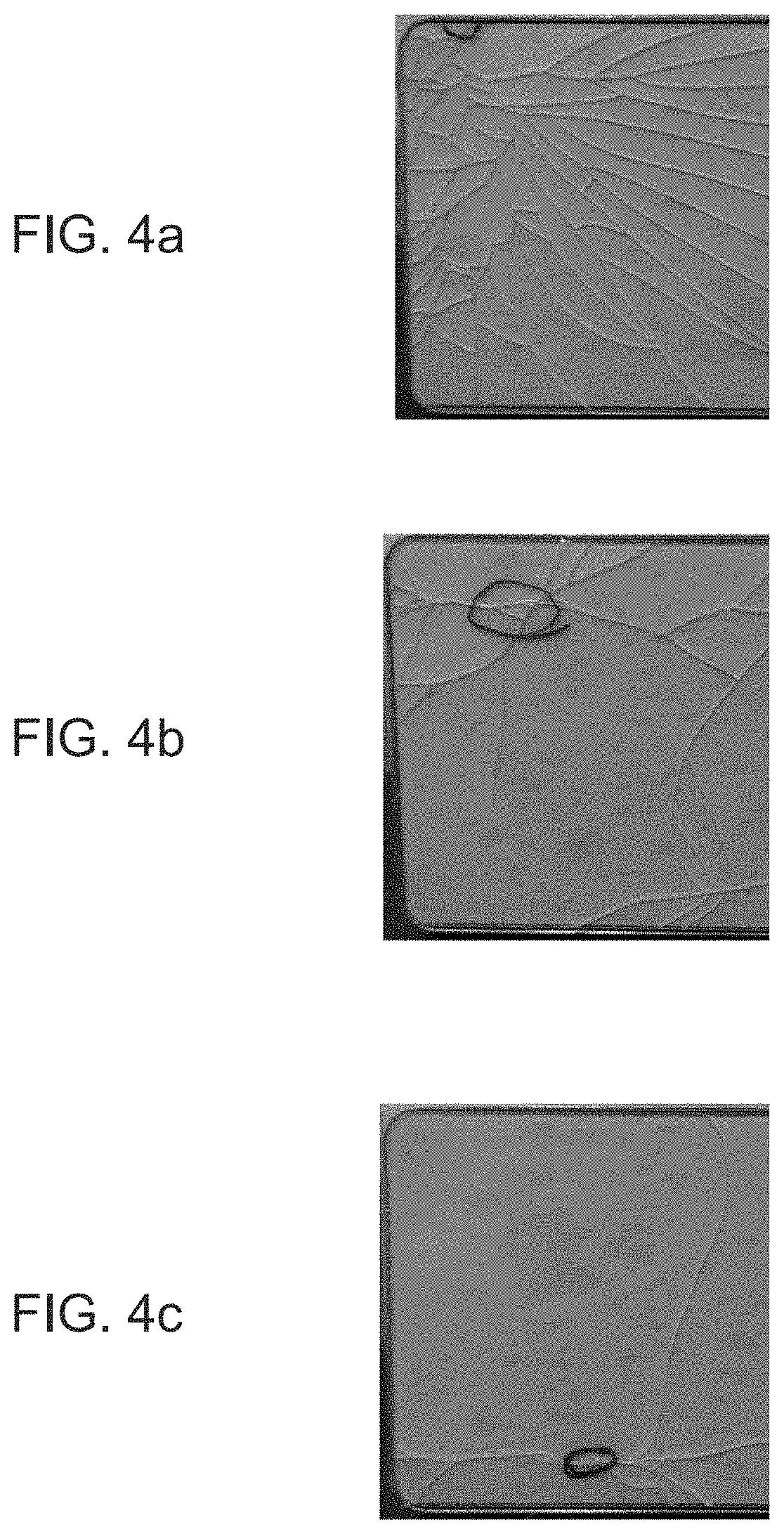

Plate-shaped, chemically prestressed glass articles and methods for producing

PendingUS20210039989A1Suitable for processingHigh mechanical strengthAlkali metal oxideUltimate tensile strength

Plate-shaped, chemically prestressed glass articles as well as methods for producing such chemically prestressed glass articles are provided. The glass article has a glass with a composition comprising SiO2, Al2O3, and Li2O and a set-drop strength from 50 to 150. The glass has at least one feature selected from: a sodium exchange depth, a storable tensile stress, a network former content of at least 82 wt %, a content of alkali oxides of at most 12 wt %, a content of alkali oxides of at most 10 wt %, and any combinations thereof.

Owner:SCHOTT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com