Automatic battery swapping platform and swapping station for electric vehicles

A technology for electric vehicles and battery swapping stations, which is applied in the field of automatic battery swapping platforms and swapping stations. It can solve the problems of poor structural stability of stacked battery packs, large space occupied by the lifting mechanism at the bottom, and long battery pack swapping time, so as to save large power Motor drive, improved user experience, and short exchange time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

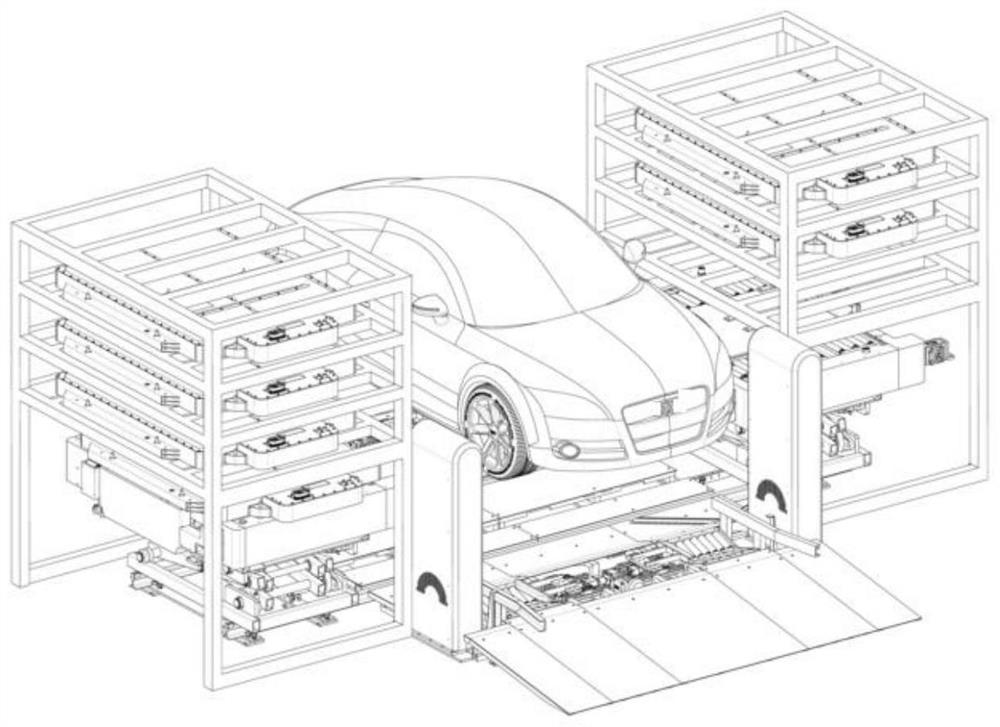

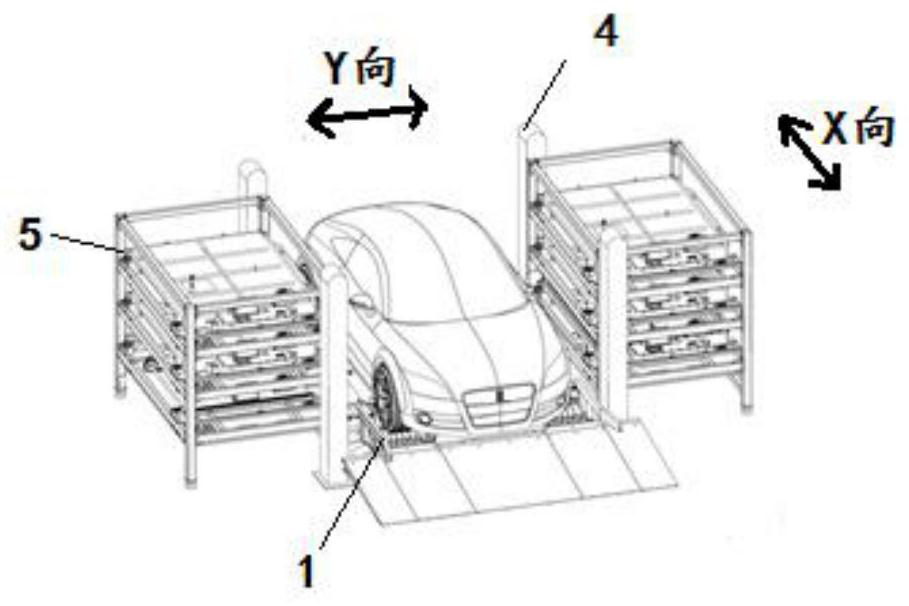

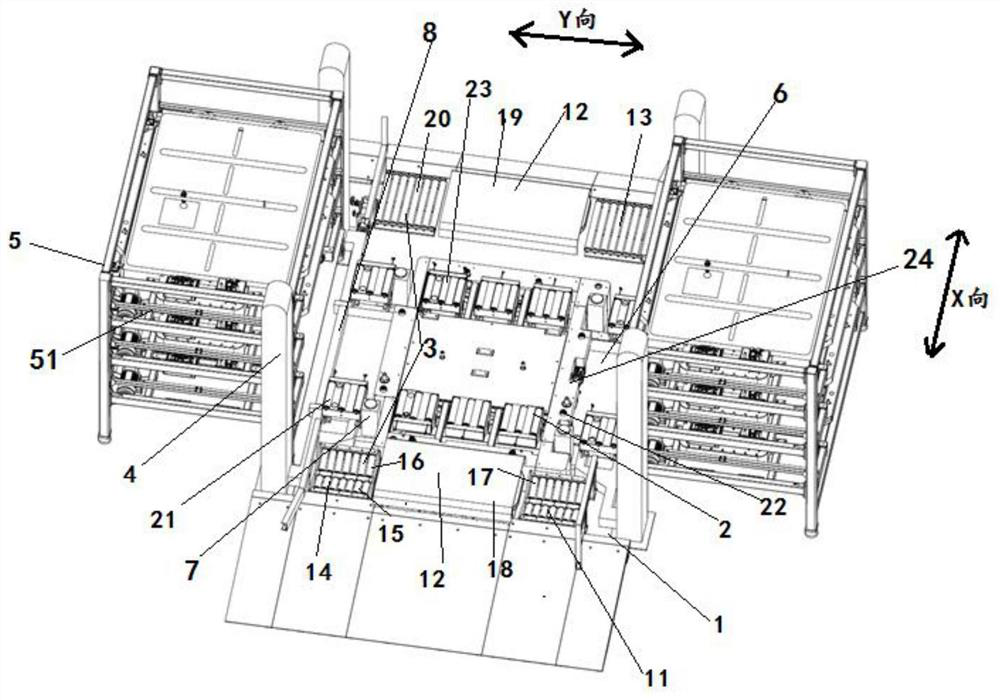

[0040] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following is a specific implementation of an automatic battery exchange platform and a battery exchange station for electric vehicles proposed in accordance with the present invention in conjunction with the accompanying drawings and preferred embodiments. The method and its effects are described in detail below.

[0041] Such as Figure 2-4 As shown, the embodiment of the present invention provides an automatic battery exchange station for electric vehicles and its battery exchange platform 1. The battery exchange platform 1 includes a battery exchange mechanism 2, a support positioning mechanism 3 and a lifting mechanism 4, wherein the battery exchange mechanism 2 is used for To perform the battery replacement operation, the battery replacement mechanism 2 includes a tightening gun 22 and a battery transmission part 21. The tighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com