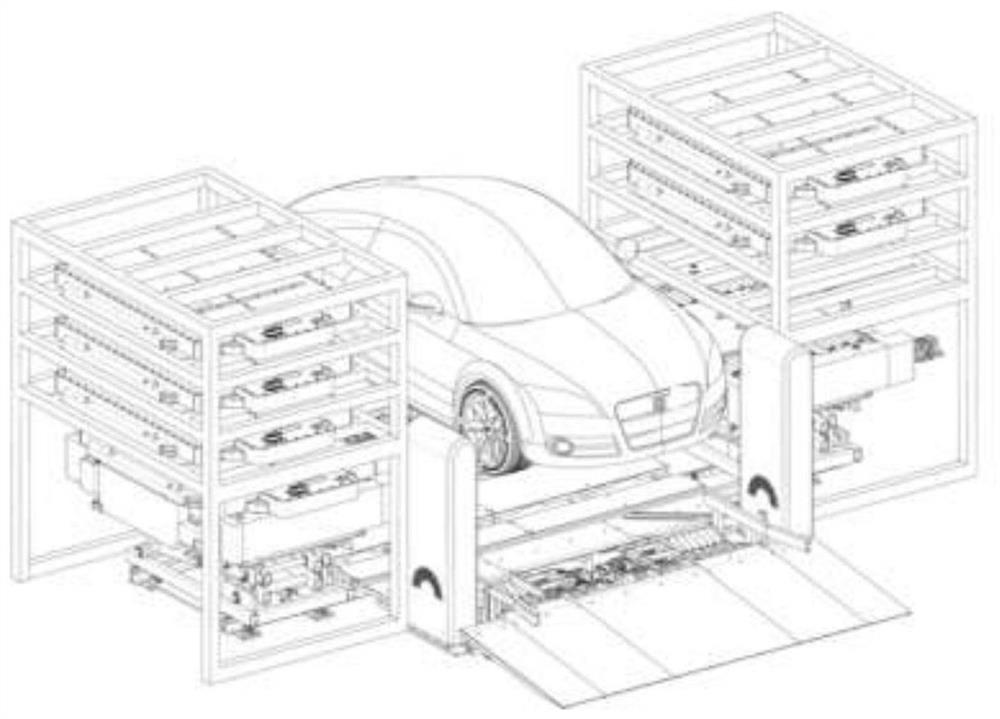

Automatic battery swapping platform and swapping station for electric vehicles

A technology for electric vehicles and power exchange stations, applied in the field of automatic power exchange platforms and power exchange stations, can solve the problems of complex power exchange process, complex structure, and many motor drives, so as to achieve simple battery exchange process, simple power exchange process, and increased storage. effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It should be noted that the battery pack of the present invention includes a depleted battery pack and a full battery pack. Depleted battery pack

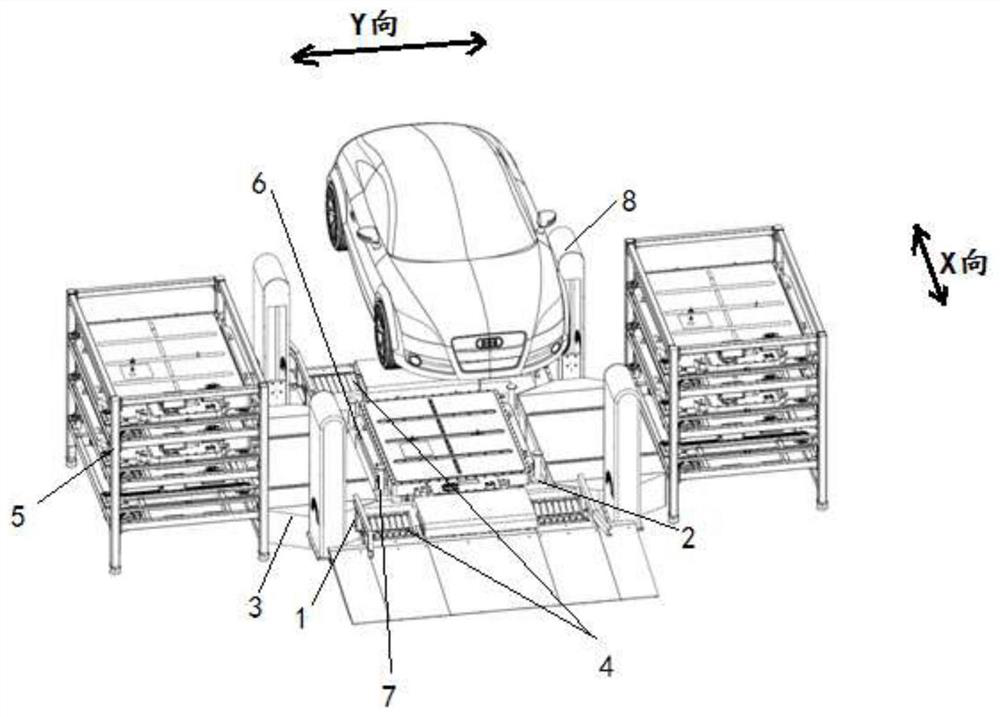

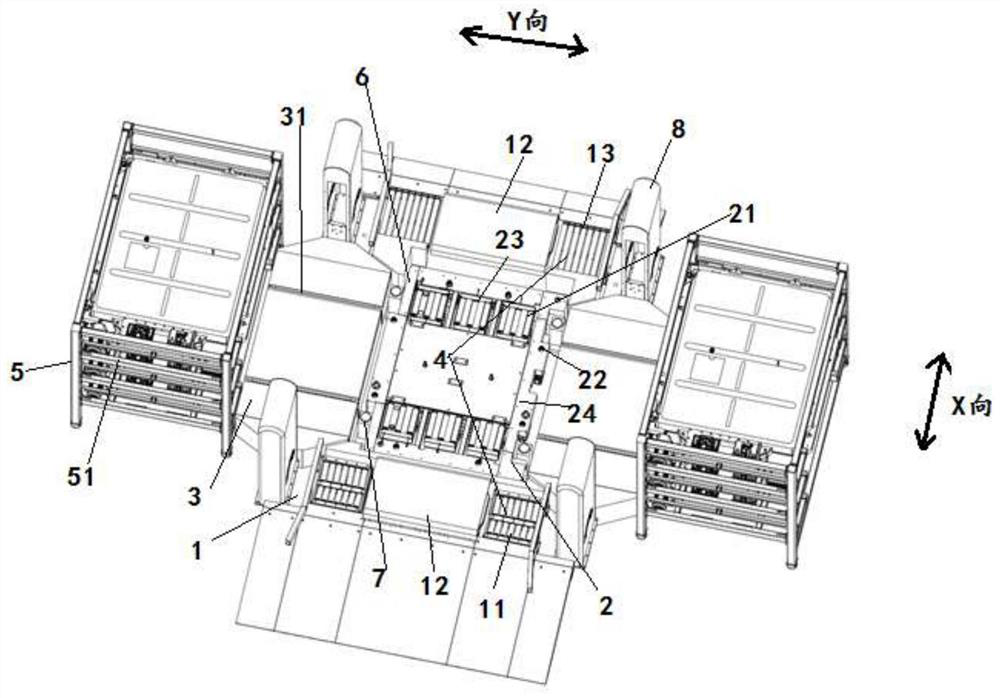

[0052] As an example, the battery pack storage device 5 has multiple layers of battery pack storage units 51 arranged in the height direction;

[0056] The battery transmission portion 21 includes a plurality of in-line roller seats 23, which are arranged at intervals along the Y direction, and the in-line roller seats 23 include a plurality of roller seats.

[0057] Considering that the installation positions of the battery packs of different vehicle models may be different, for example, the position of the battery packs of some vehicles is located in the vehicle.

[0062] In order to increase the storage quantity of the battery pack, the battery pack storage unit 51 may be provided in not less than three layers. battery per layer

[0069] In addition, the automatic power exchange station also includes a charging device (not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com