Method and device for forming flaskless cope and drag, and method of replacing matchplate

The technology of a double-sided template and a manufacturing method, which is applied to manufacturing tools, casting molding equipment, molding machines, etc., can solve the problems that the quality of the casting mold needs to be improved, the exchange of the double-sided template is inconvenient, the efficiency of the molding device is low, and the like, and achieves effective molding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

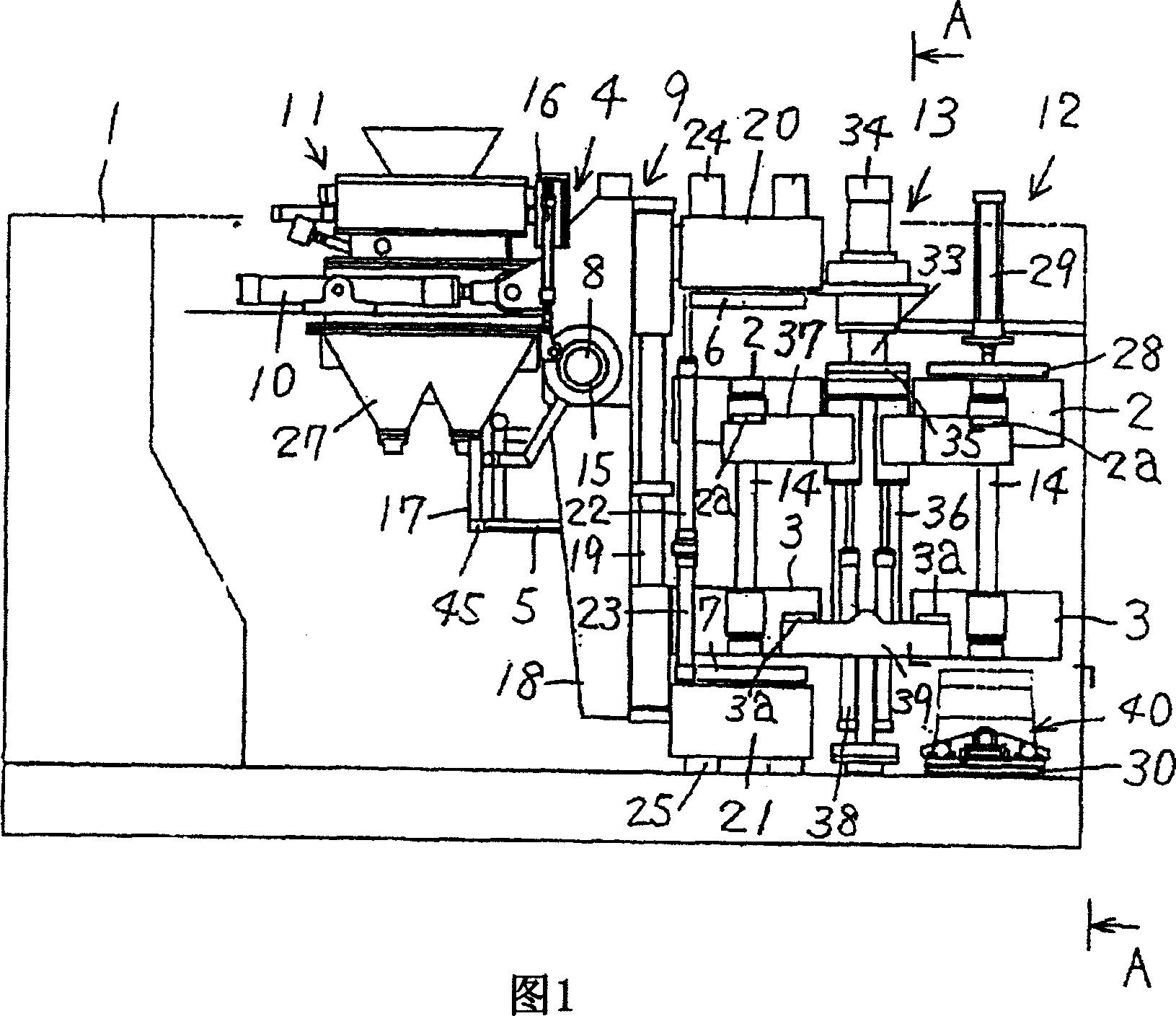

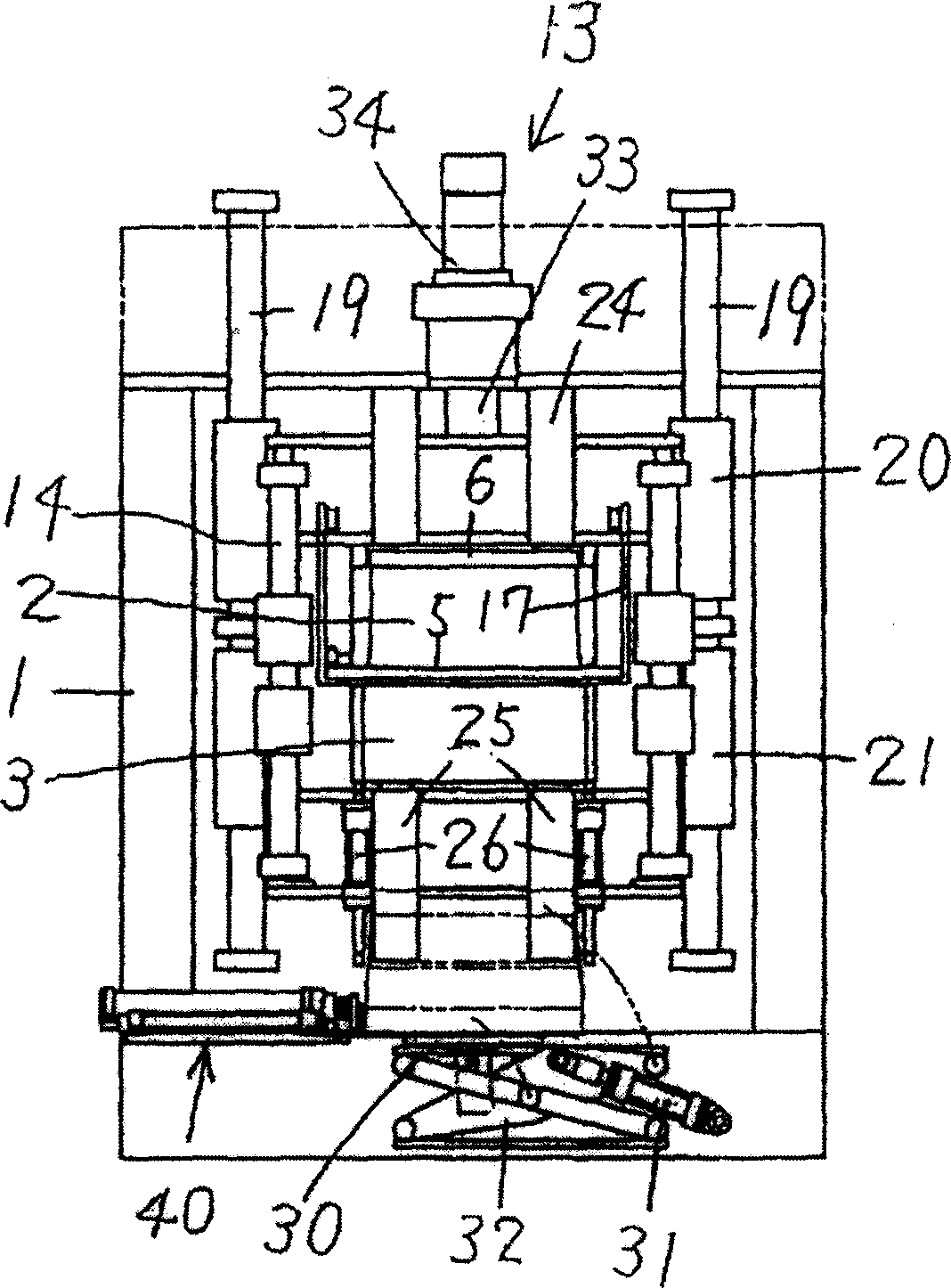

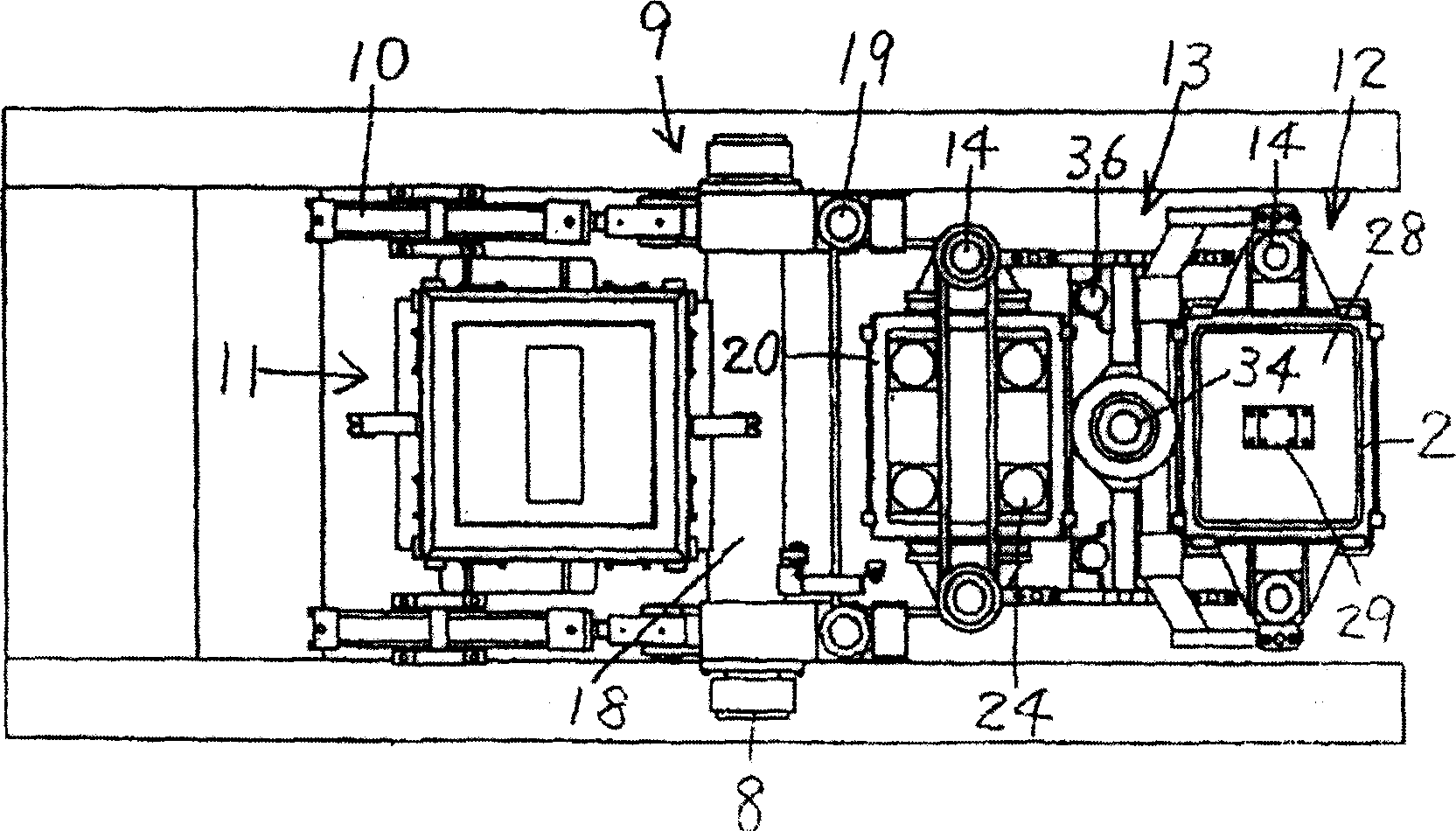

[0125] Embodiments of the manufacturing apparatus of the upper and lower casting molds without a sandbox according to the present invention will be described in detail below with reference to the accompanying drawings.

[0126] Figure 1- image 3 As shown, the manufacturing device of the upper and lower casting molds without sandbox uses the upper and lower extrusion plates as the extrusion device.

[0127] The manufacturing device of the upper and lower casting molds without a sandbox structurally includes:

[0128] a machine 1 of rectangular shape with an inner space;

[0129] Two pairs of mold-making upper boxes and mold-making lower boxes 2, 3, 2, 3 respectively provided with molding sand blowing inlets on the side walls;

[0130] Through the delivery of the transport device 4, the double-sided template 5 can enter and exit between the pair of upper molding boxes and the lower molding boxes 2, 3 of the two pairs of molding upper boxes and molding lower boxes 2, 3, 2, 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com