A kind of preparation method of antibacterial glass and antibacterial vacuum glass

A technology of antibacterial glass and vacuum glass, which is applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of easy oxidation of antibacterial ions, decrease of glass transmittance, complex process, etc., to achieve favorable performance and transmittance Light performance, avoiding the decrease of light transmittance, simple and effective method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

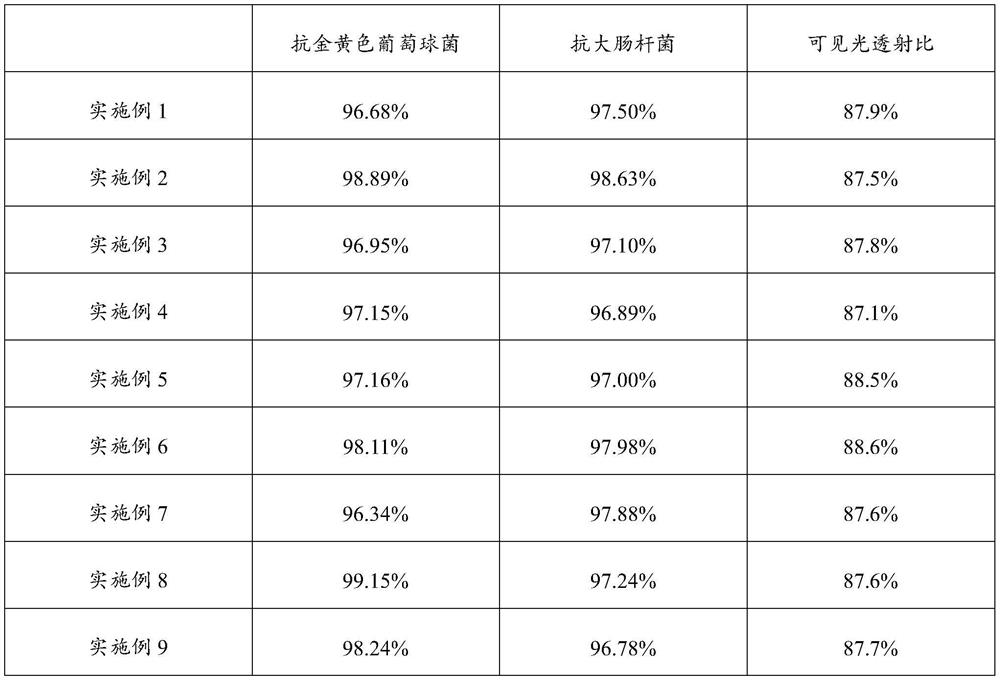

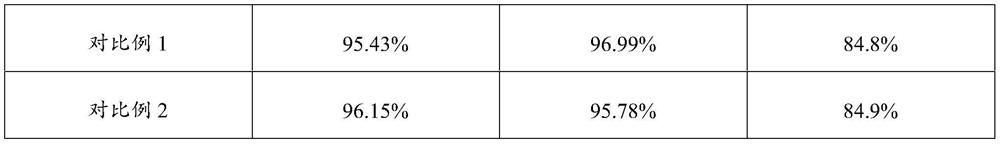

Examples

Embodiment 1

[0042] Embodiment 1 (embodiment 1-6 is chemical method)

[0043] The present embodiment provides a kind of preparation method of antibacterial glass, concrete steps are:

[0044] Cut the original glass sheet with a thickness of 4mm, put it into the mixed molten salt of potassium nitrate, silver nitrate and ferrous sulfate, in which the mass fraction of silver ions is 0.1%, and the mass concentration of ferrous ions is 0.2%. Conditions, ion exchange for 2 minutes, then the glass is taken out, cooled and cleaned to obtain the antibacterial glass.

Embodiment 2

[0046] The present embodiment provides a kind of preparation method of antibacterial glass, concrete steps are:

[0047] Cut the original glass sheet with a thickness of 4mm and put it into the mixed molten salt of potassium nitrate, silver nitrate and ferrous sulfate, in which the mass fraction of silver ions is 3%, and the mass concentration of ferrous ions is 1.5%. Under the condition of ℃, ion exchange for 1 minute, then the glass is taken out, cooled and washed to obtain the antibacterial glass.

Embodiment 3

[0049] The present embodiment provides a kind of preparation method of antibacterial glass, concrete steps are:

[0050] Cut the original glass sheet with a thickness of 4mm, put it into the mixed molten salt of potassium nitrate, silver nitrate and ferrous sulfate, in which the mass fraction of silver ions is 0.01%, and the mass concentration of ferrous ions is 0.01%. Conditions, ion exchange for 10 minutes, then take out the glass, cool and wash to obtain the antibacterial glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com