Double-station efficient worm-grinding-wheel computer numerical control gear grinding machine

A worm grinding wheel, dual-station technology, applied in the direction of worm, mechanical equipment, components with teeth, etc., to avoid the poor rigidity of tangential string cutter movement, improve production efficiency, and high overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

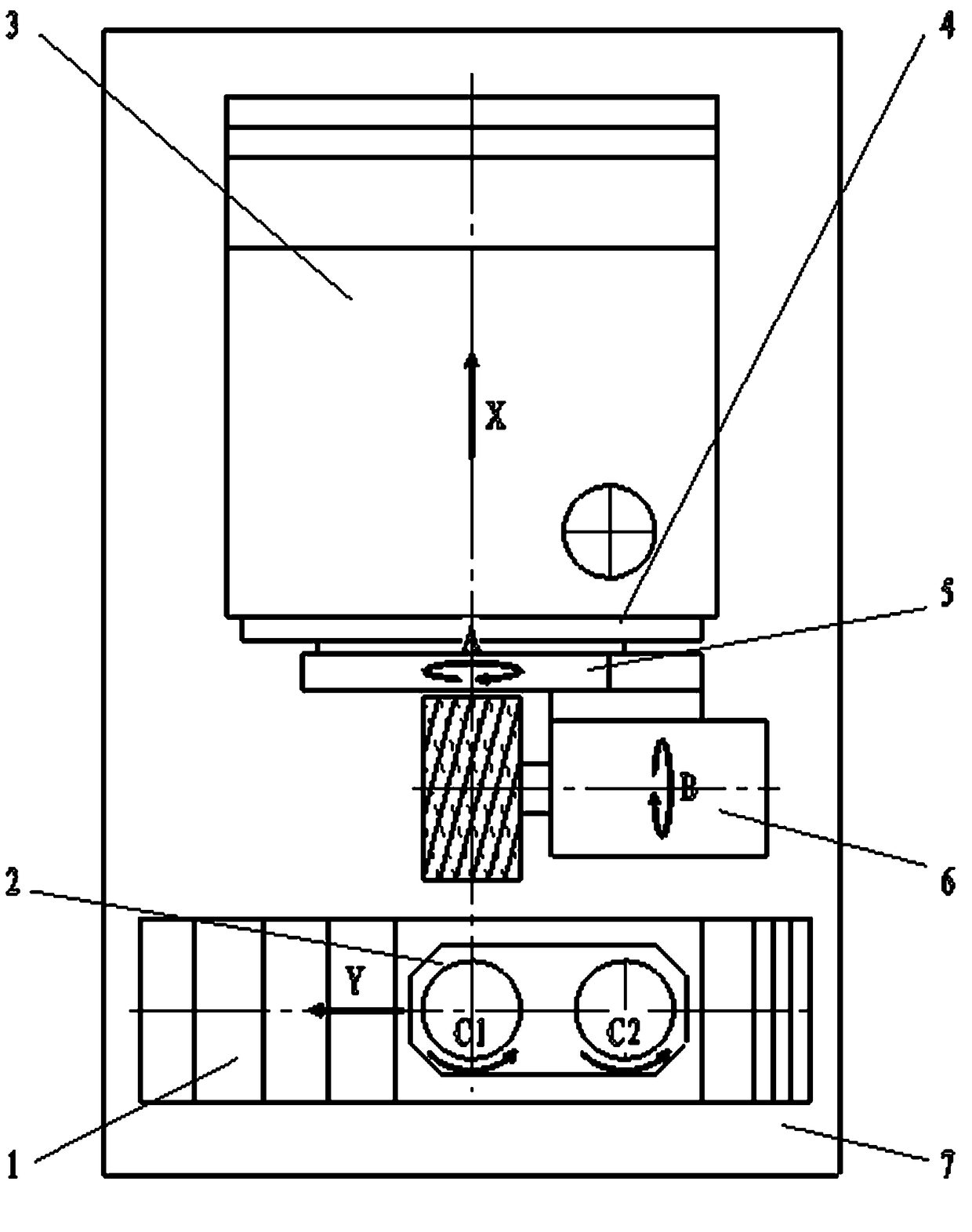

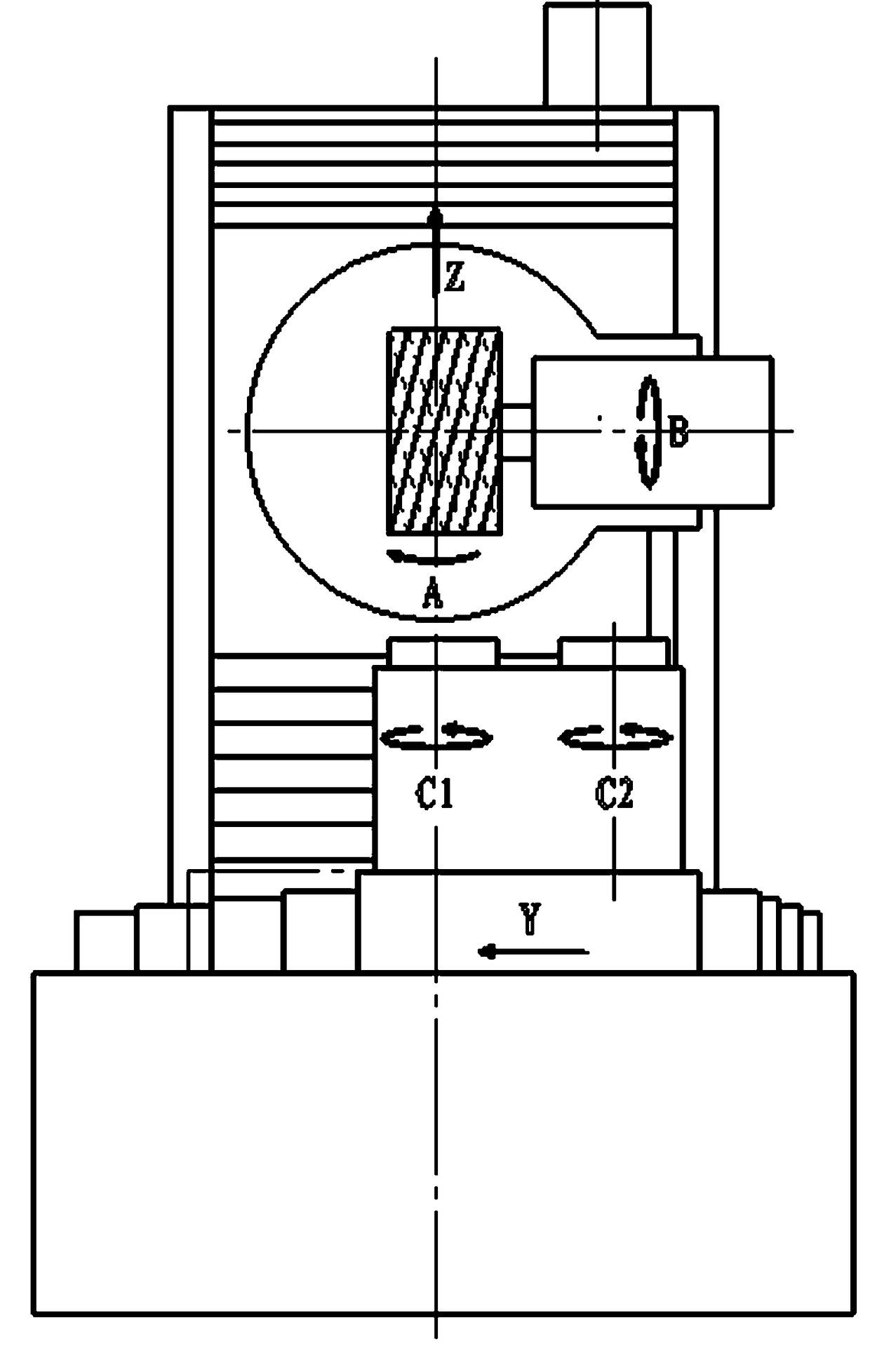

[0011] like Figure 1-2 As shown, the present invention is a dual-station high-efficiency worm wheel CNC gear grinding machine, including a mobile workbench 1, a double workpiece spindle 2, a column 3, a vertical slide box 4, a turntable 5, a grinding wheel spindle 6 and a bed 7 , the mobile worktable 1 is installed on the front part of the bed 7 through horizontal linear guide rails in the left and right directions, and the double workpiece spindle 2 is installed on the mobile workbench 1 along the left and right directions of the mobile workbench 1 , the two axes of rotation of the double workpiece spindle 2 are in a vertical state, the bottom of the column 3 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com