Automatic saw blade gear grinding machine

A saw blade grinding machine, automatic technology, applied in metal sawing equipment, tool dressing of sawing machine devices, metal processing equipment, etc., can solve the problems of low processing efficiency, long processing time, high manufacturing cost, etc. The effect of high efficiency, high grinding precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

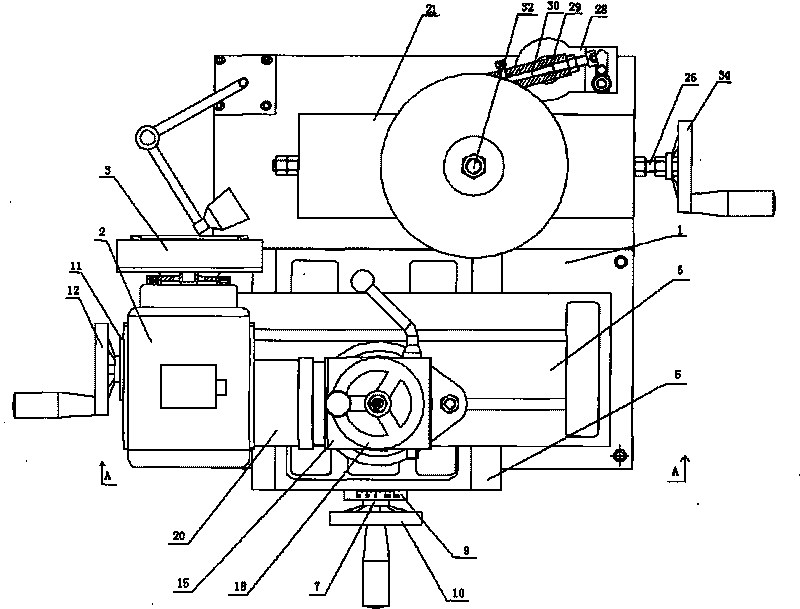

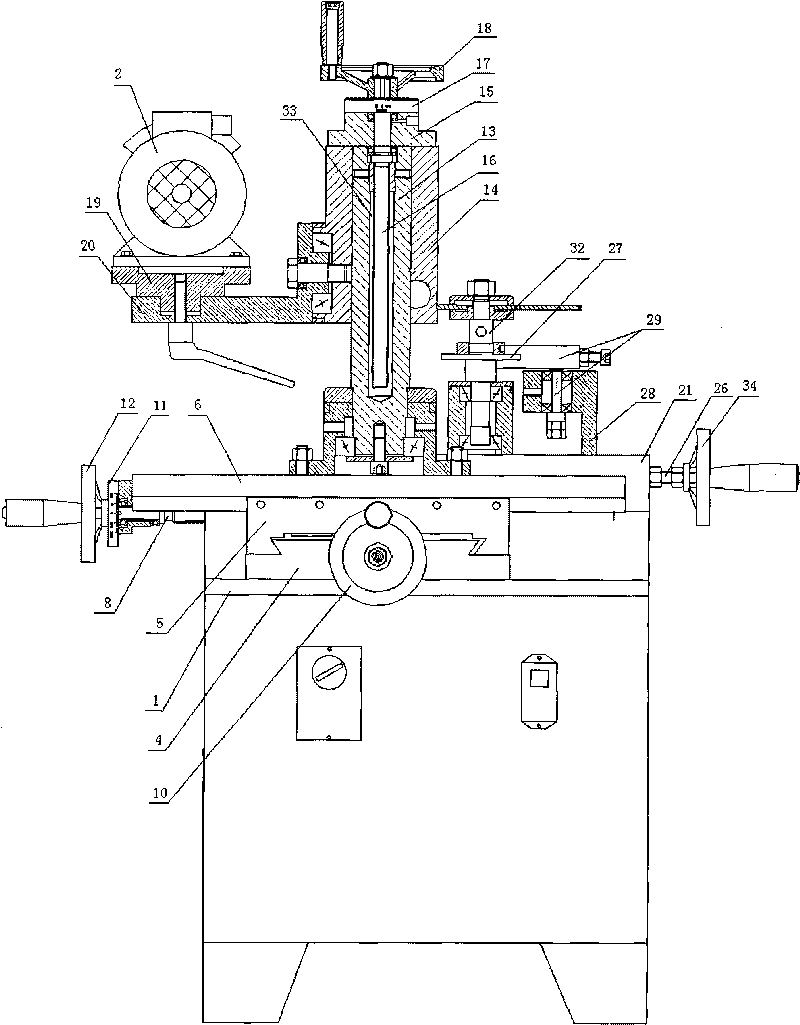

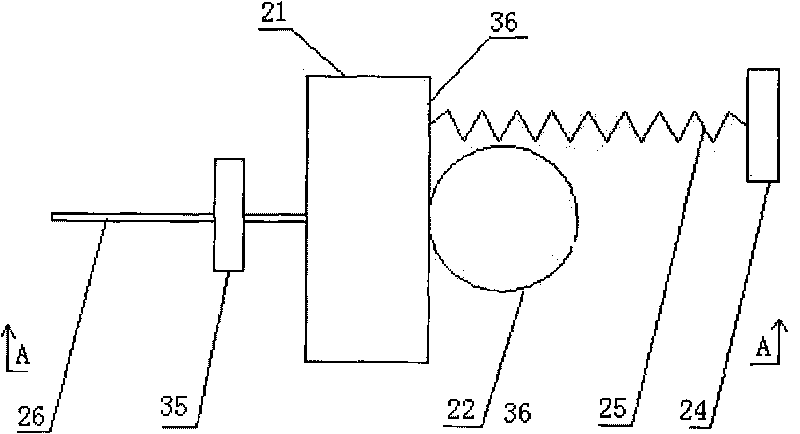

[0022] see figure 1 and figure 2 , the automatic saw blade gear grinding machine mainly includes a base 1, a motor 2, a grinding wheel 3 installed on the main shaft of the motor 1, a saw blade shifting device, and a motor displacement adjustment device for adjusting the lateral displacement and longitudinal displacement of the motor 2 on the base 1 1. A motor lift adjustment device for adjusting the distance between the motor 2 and the base 1, and a motor angle adjustment device for adjusting the rotation angle of the motor 2 in the horizontal plane and in the vertical plane. The motor displacement adjustment device is installed on the base 1, the motor lifting adjustment device is rotatably installed on the motor displacement adjustment device and can be locked and positioned by fasteners, and the motor angle adjustment device is rotatably installed on the motor lifting adjustment device and can be positioned by fasteners Locking and positioning, the motor 2 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com