Spiral bevel gear and hypoid gear forming method large-gear grinding machine

A technology of hypoid gears and spiral bevel gears, which is applied in the field of numerical control processing equipment, can solve problems such as uneconomical and cumbersome, and achieve the effects of saving gear grinding time, small footprint, good stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

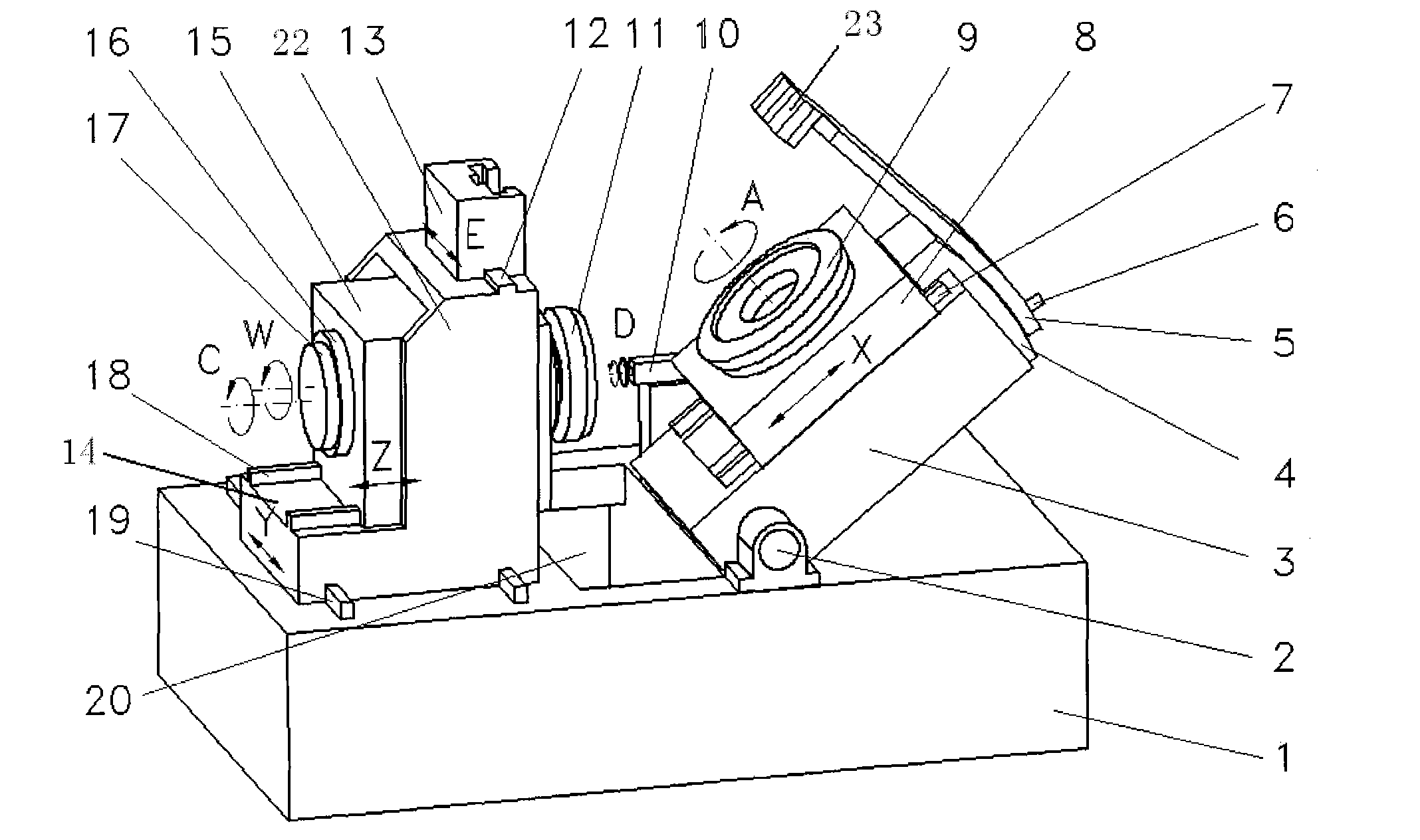

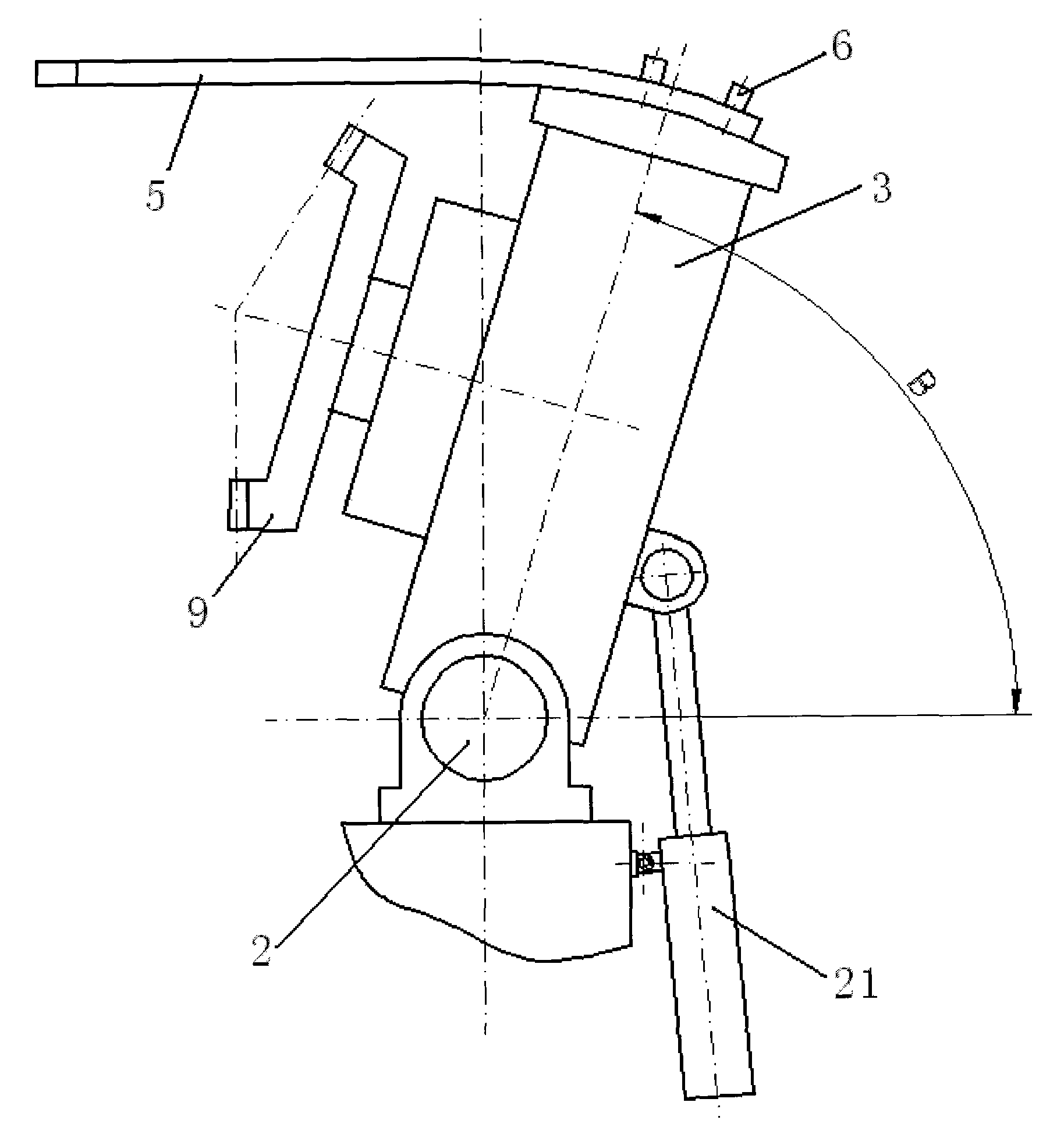

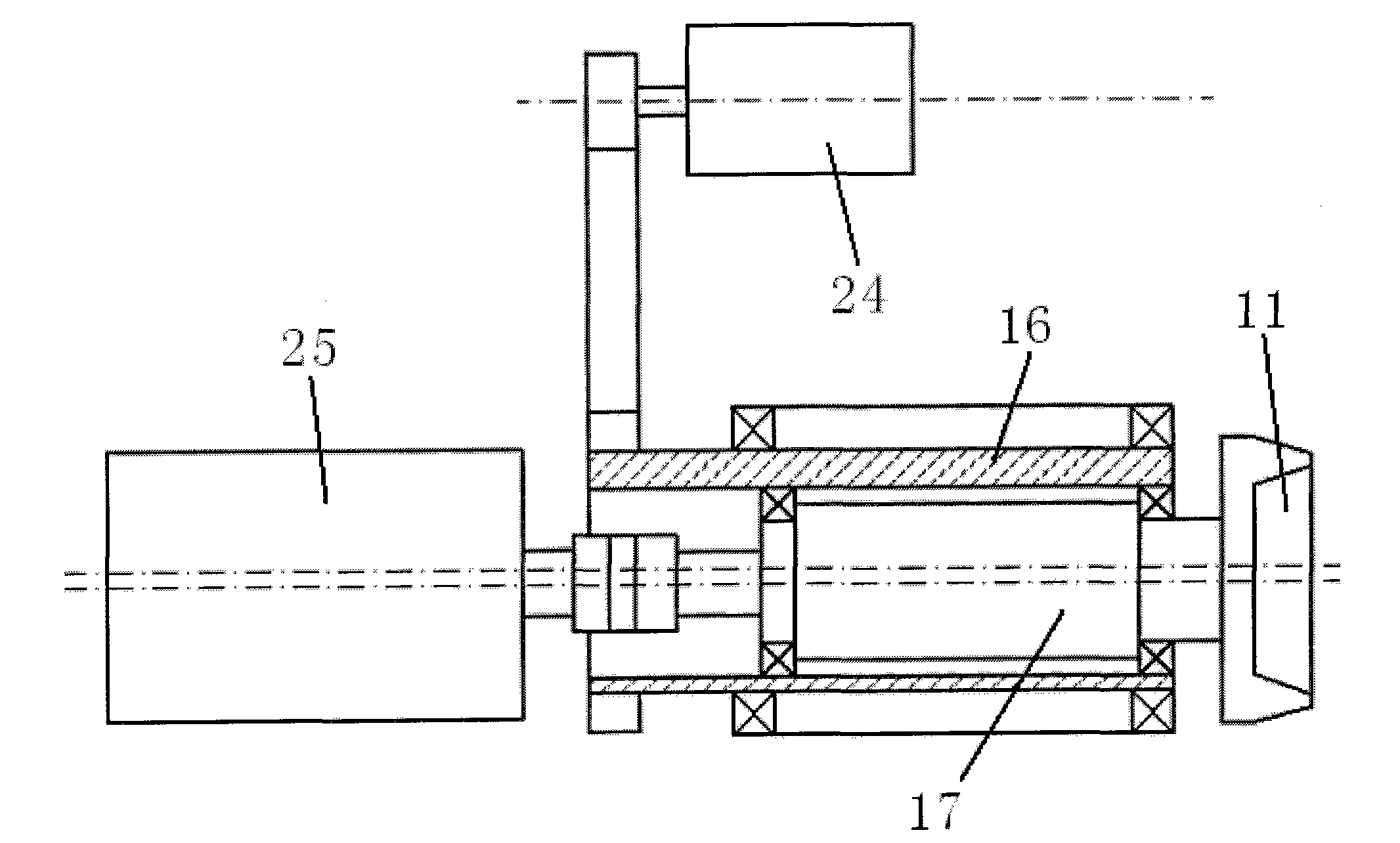

[0026] according to figure 1 The large-wheel gear grinding machine for spiral bevel gears and hypoid gears with the above structure has a bed 1, and a horizontal Y-axis linear guide 19 is provided on one side of the top surface of the bed 1. The Y-axis linear guide 19 is equipped with a Y-axis slide 14 that can move along the Y-axis linear guide 19 under the drive of the drive mechanism; the Y-axis slide 14 is equipped with a Z-axis linear guide 18 that is perpendicular to the Y-axis linear guide 14 and is horizontally arranged. The Z-axis linear guide rail 18 is equipped with a grinding wheel box 15 that can move along the Z-axis linear guide rail 18 under the action of the driving mechanism; the grinding wheel box 15 is equipped with a W-axis 16 driven by the driving mechanism, and the W-axis 16 is parallel to the Z-axis linear guide rail 18 An eccentric C-axis 17 that can be driven by the drive mechanism to rotate is installed in the W-axis 16, and one end of the eccentric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com