High-precision end-tooth automatic dividing device for gear grinding machine

An automatic indexing and gear grinding machine technology, which is applied in gear tooth manufacturing devices, gear cutting machines, gear teeth, etc., can solve the problems of structure and performance differences, unsuitable for gear grinding machine assembly and use, etc., and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

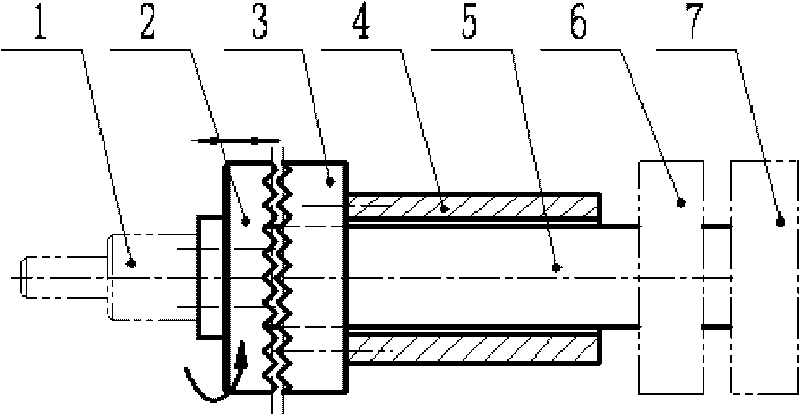

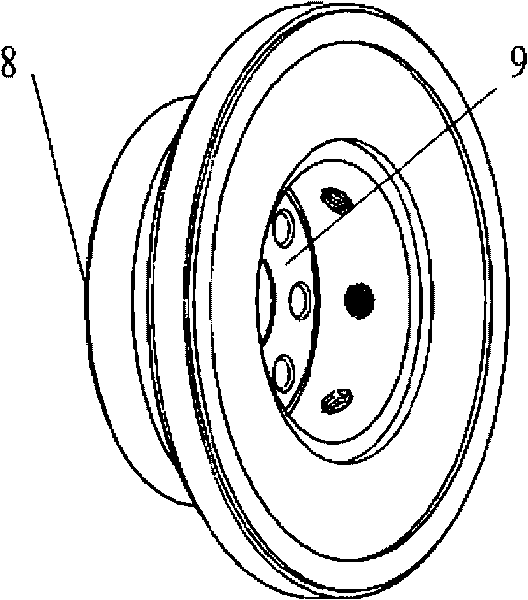

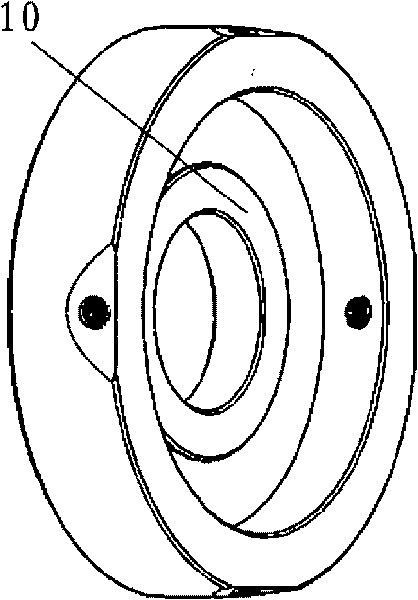

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0021] The function of the present invention is the same as the original indexing system of the machine tool, all of which are to realize the indexing of the grinding teeth, and the difference is the precision indexing element and the installation position in the indexing system. In the present invention, the tooth plate at the grab end of the precision indexing element is close to the workpiece to be ground, and the torsional deformation of the shaft has little influence on the indexing accuracy; while the indexing plate in the original machine tool is far away from the workpiece to be ground, the torsional deformation of the shaft has little effect on the indexing accuracy. Accuracy is greatly affected. In addition to the characteristics of the end gear plate itself, the indexing device has the highest indexing accuracy a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com