Grinding force model for worm-shaped grinding wheel gear grinding

A grinding wheel grinding and grinding force technology, applied in the field of grinding force model, can solve problems such as difficulty in establishing a grinding force model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention is described below in conjunction with concrete processing example:

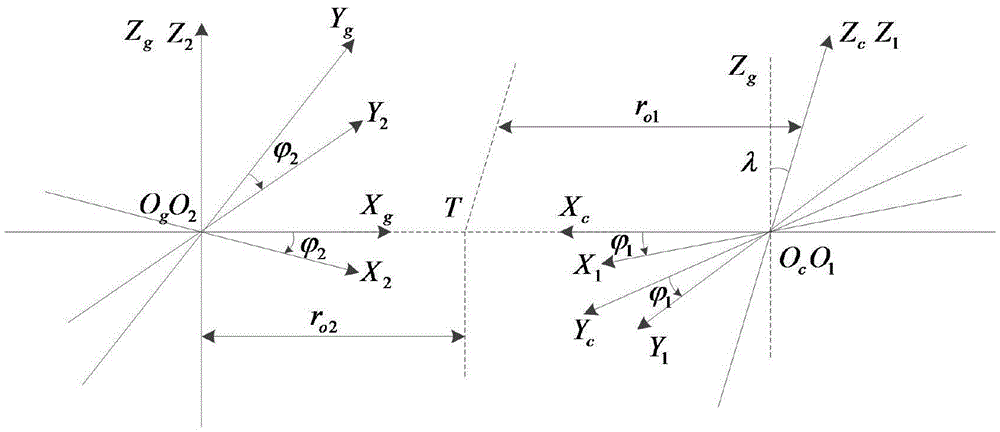

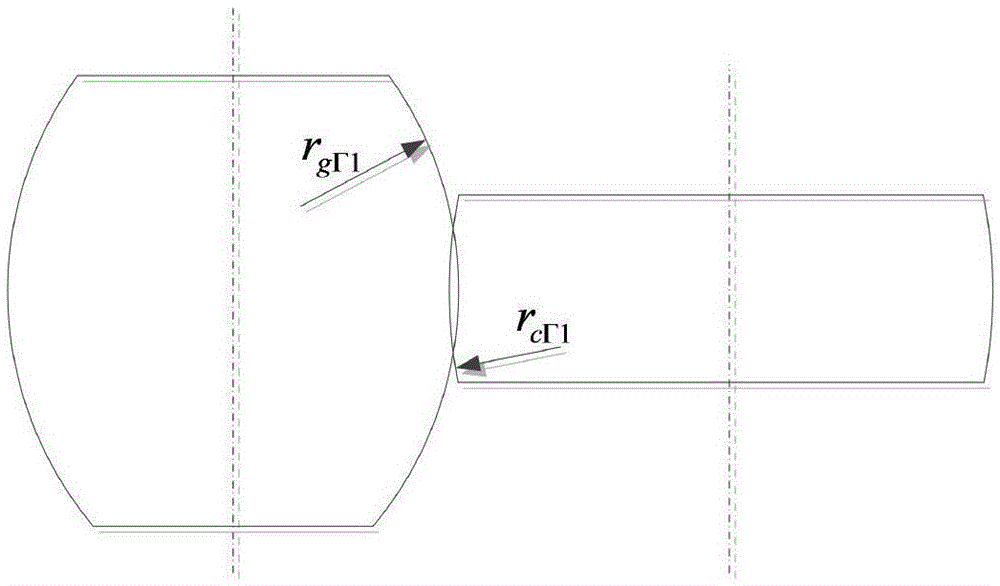

[0067] Using worm grinding wheel grinding technology to process helical cylindrical gears, processed gear parameters: normal pressure angle α n2 =27.5°, normal modulus m n2 =3, number of teeth Z 2 =27, helix angle β 2 =18°, dextrorotation. Parameters of worm-shaped grinding wheel: normal pressure angle α n1 =27.5°, normal modulus m n1 = 3, number of heads Z 1 =4, helix angle γ 1 =8°, dextrorotation. Shaft intersection angle λ=100°, center distance a=85.696.

[0068] S1. Establish an approximate model of the grinding process

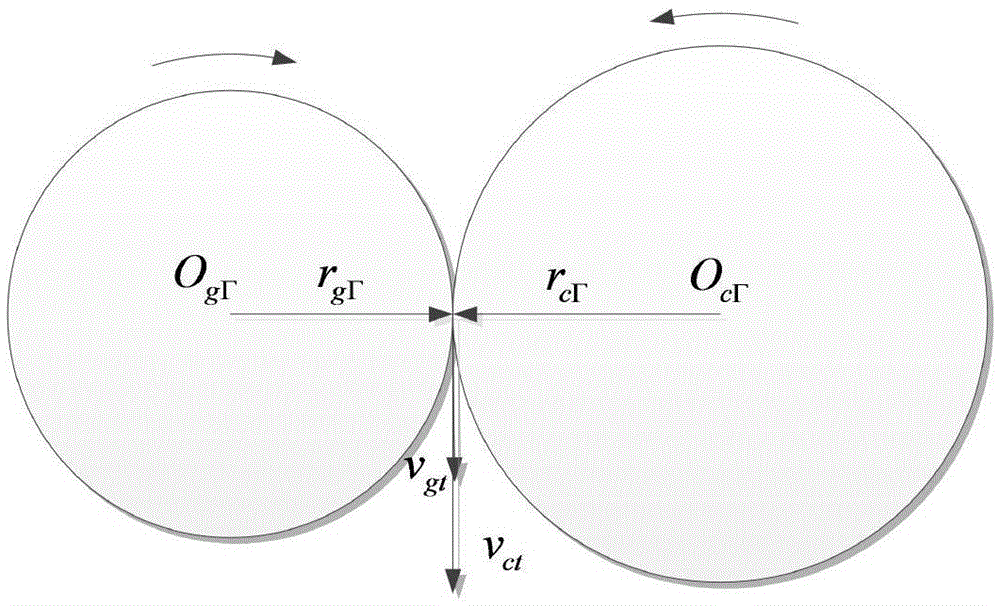

[0069] During the gear grinding process, the theoretical tooth surface of the gear to be machined and the surface of the grinding wheel mesh in a spatially interlaced axis, and the contact condition is point contact. The coordinate system is as follows: figure 1 . According to the principle of meshing, at the contact point, the relative velocity b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com