Axial sealing strip with self-pressing characteristic for high-power scroll compressor

A scroll compressor and axial sealing technology, which is applied to the sealing device of piston pumps, rotary piston machinery, mechanical equipment, etc., can solve the problems of large compression ratio, sharp increase and rise of axial clearance, etc., and achieve no leakage reduction , the effect of suppressing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Attached below Figure 1-9 Shown concrete example, the present invention is described further:

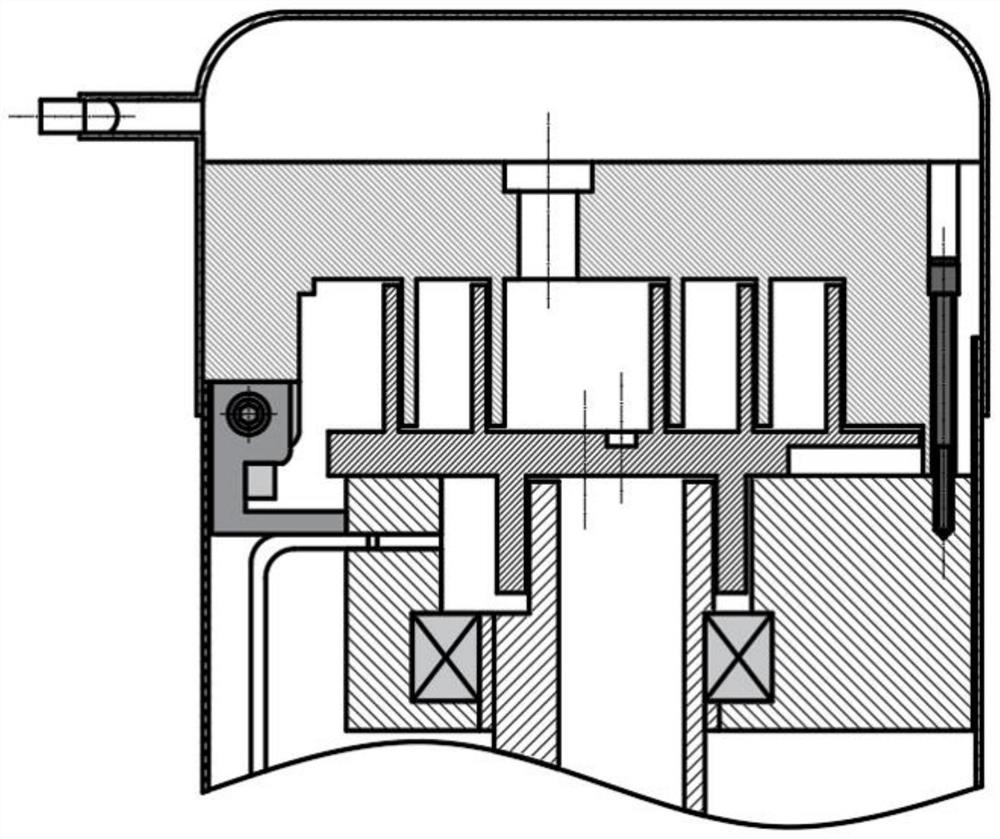

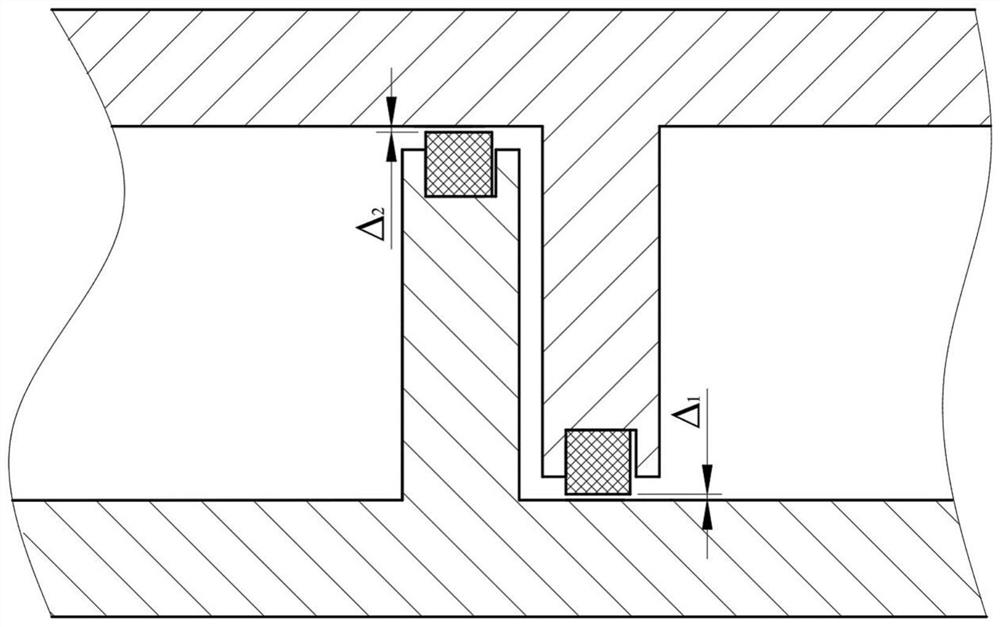

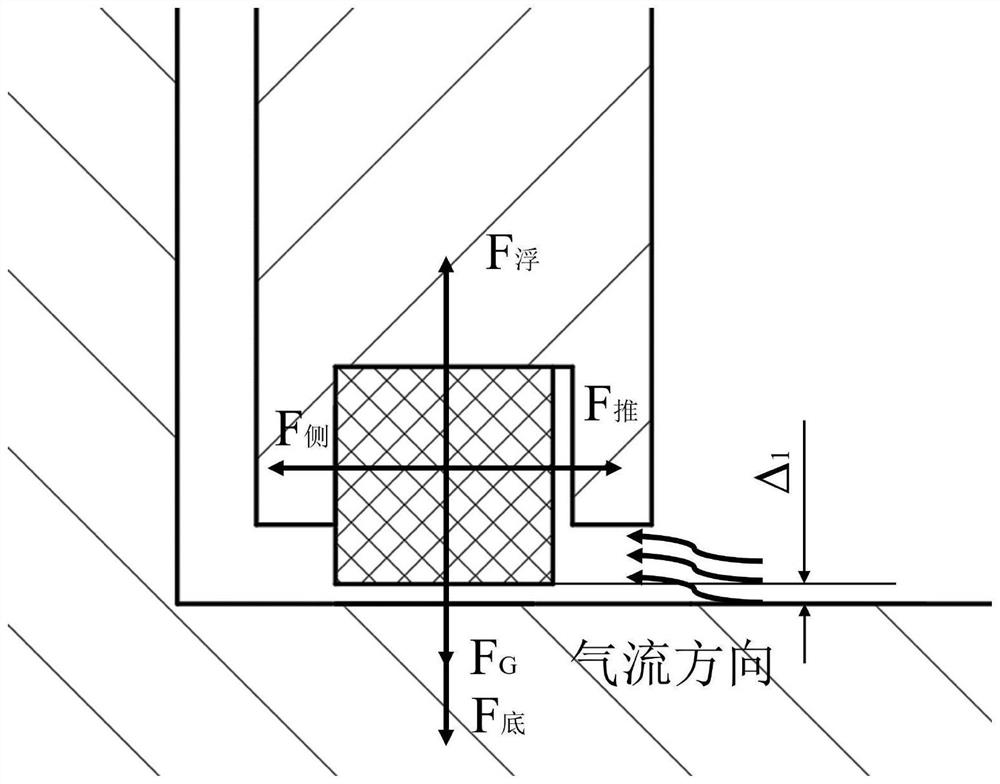

[0029] An axial sealing strip with self-compressing characteristics for a high-power scroll compressor. The sealing strip body has a spiral structure, the cross section of the sealing strip body is trapezoidal, and the scroll is opened with a groove that is consistent with the cross-sectional shape of the sealing strip body. The groove, the trapezoid and the groove cooperate to seal, the cross-sectional shape of the scroll and the sealing strip are trapezoid, the size and structure are single, easy to process, and can meet the needs of mass production. The assembly drawing of the sealing strip and the vortex is as follows: Figure 8 As shown, the sealing strip fits closely with the scroll groove, and the height is consistent with the groove.

[0030] The scroll includes a fixed scroll 1 and a movable scroll 3, the groove of the fixed scroll 1 is provided with a sealing str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com