Agricultural small ridger

A ridge machine, a small technology, is used in agricultural machinery and implements, applications, agriculture, etc., and can solve the problems of lack of a convenient connection mechanism between a ridge plate and a support plate, reduced ridge quality, and inconvenient removal and cleaning of the ridge plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

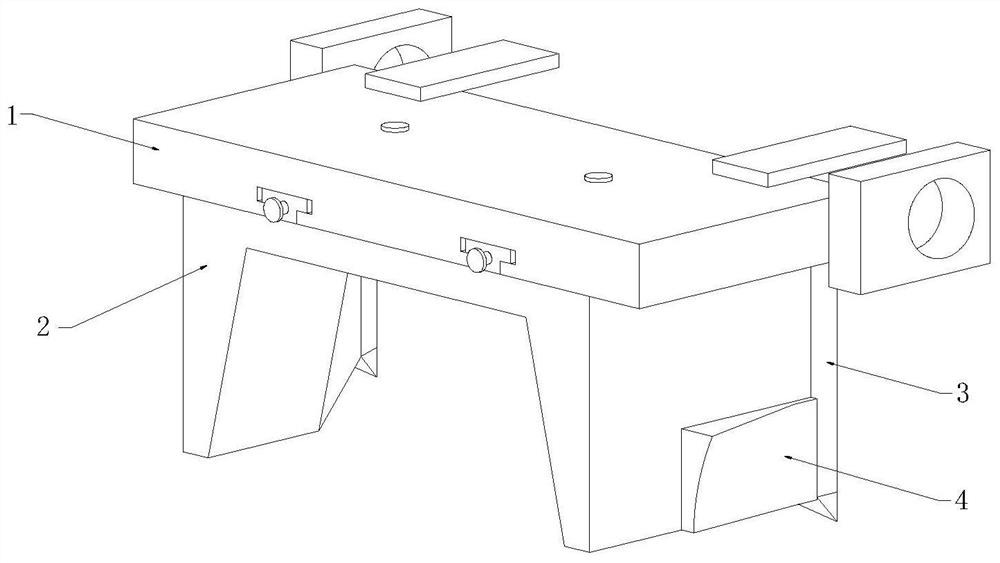

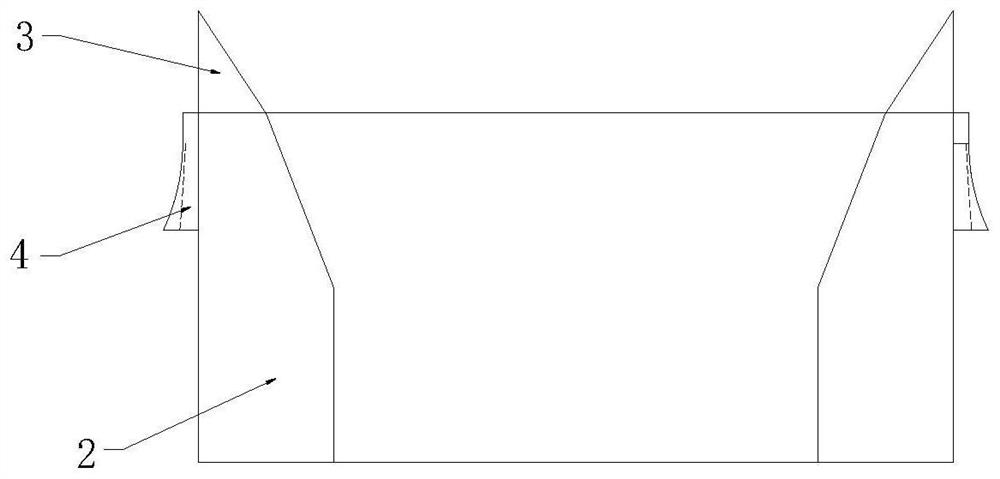

[0027] see Figure 1-4 Shown, a kind of agricultural small-sized ridging machine comprises support plate 1, ridging plate 2, plow point bar 3, soil turning plate 4 and connecting mechanism; Described support plate 1 bottom middle is installed with ridging plate 2, so The rear end of the ridging plate 2 is symmetrically installed with two plow point rods 3, and the top of the plow point rod 3 is attached to the bottom end of the support plate 1, and the lower sides of the left and right ends of the ridging plate 2 are fixedly installed with soil turning boards. 4;

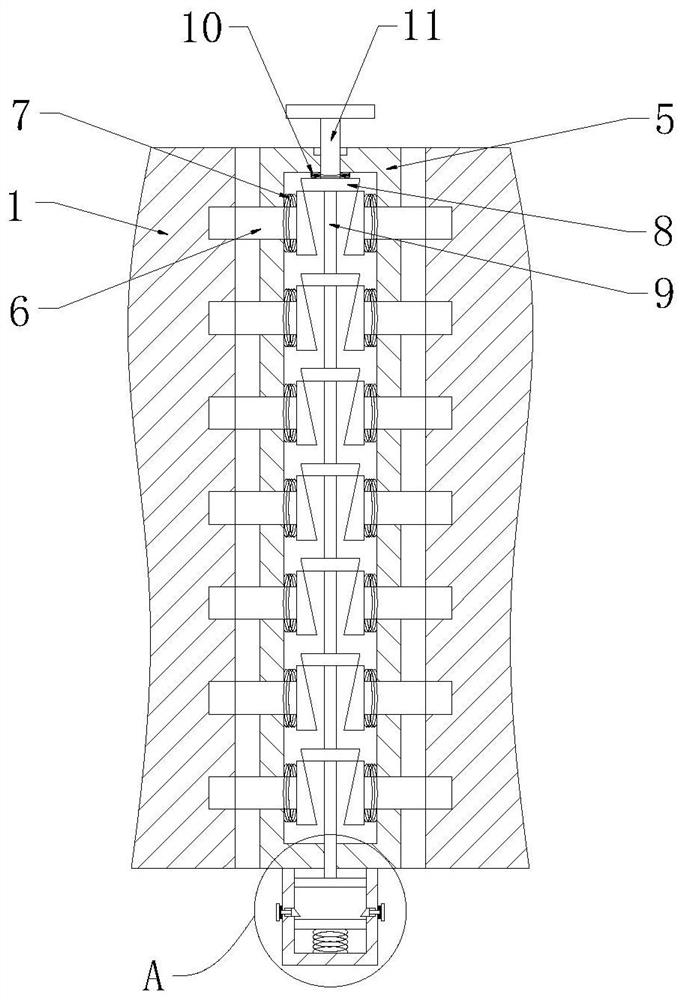

[0028] The connecting mechanism includes a T-shaped hollow rod 5, a T-shaped inclined block 6, a spring 7, a tapered block 8, a connecting rod 9 and a spring 2 10, and two T-shaped hollow rods are symmetrically fixed on the top of the ridging plate 2 5. Two T-shaped slots are arranged symmetrically at the bottom of the support plate 1, and a T-shaped empty bar 5 is installed inside the T-shaped slot, and more than ...

Embodiment 2

[0037] see Figure 5 As shown, compared with Example 1, as another embodiment of the present invention, a spring 5 20 is fixedly installed at the middle position of the inner top of the T-shaped slot, and a pointed cone block 19 is fixedly installed at the bottom of the spring 5 20. The top of the T-shaped empty bar 5 is provided with a draw-in groove, the bottom end of the pointed cone block 19 extends to the inside of the draw-in groove, the top of the support plate 1 is equipped with a T-shaped magnetic block 21, and the bottom end of the T-shaped magnetic block 21 extends to T The inside of the type groove is fixedly installed on the top of the pointed cone block 19; during work, when the T-shaped hollow rod 5 slides inside the T-shaped groove, the T-shaped empty rod 5 squeezes the pointed cone block 19, and the pointed cone block 19 Squeezed to move and squeeze the spring 5 20, when the pointed cone block 19 is aligned with the card slot, under the action of the spring fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com