Sand screening machine for construction site

A technology of construction site and sand screening machine, which is applied in the direction of screening, solid separation, grille, etc., can solve the problems of not easy screening, reducing sand screening effect, and blocking meshes by foreign objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

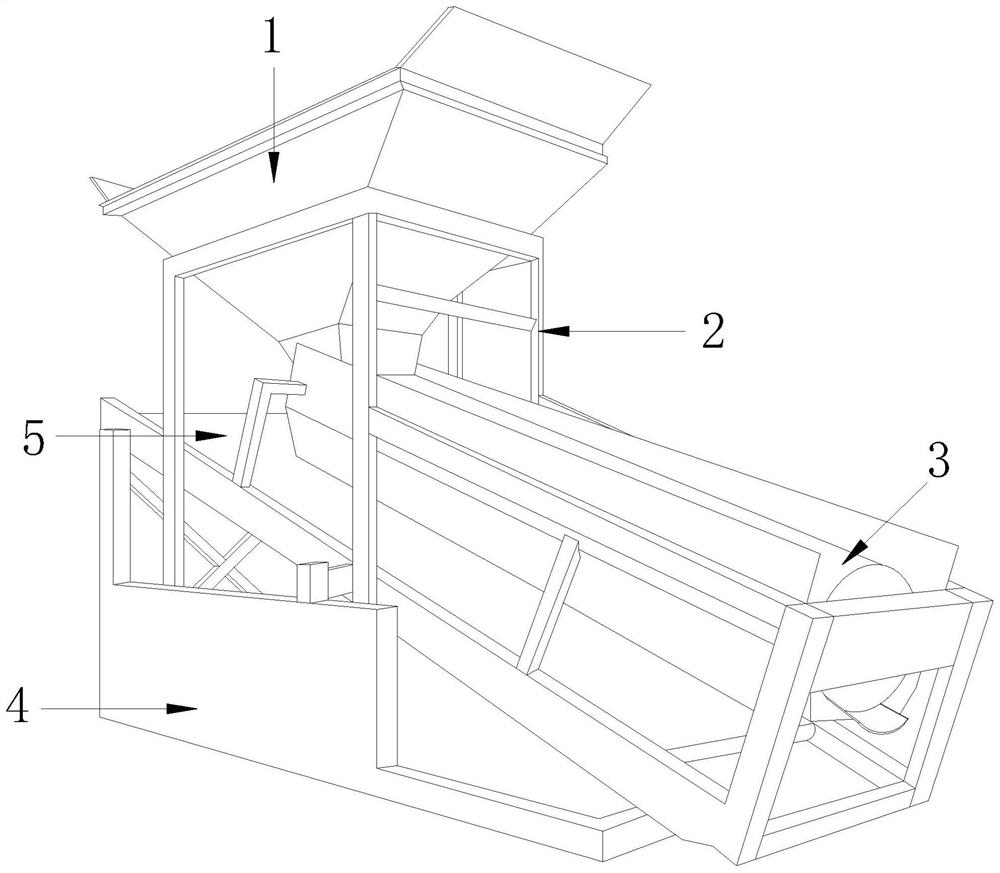

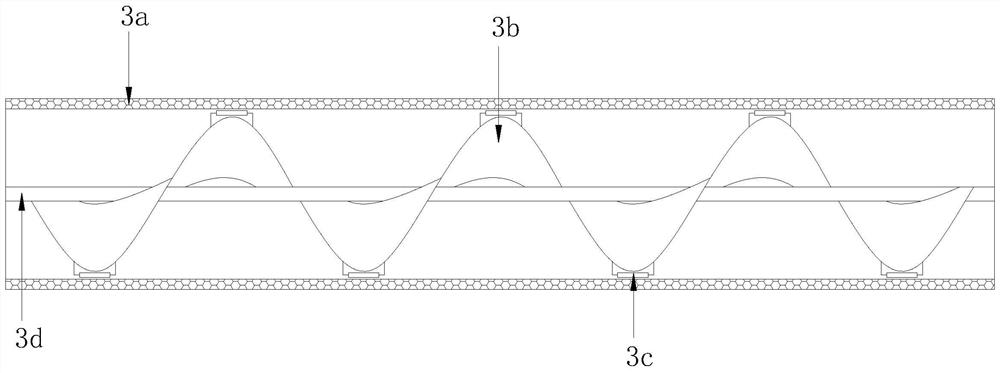

[0027] see Figure 1-2 , the present invention provides a sand screening machine for construction sites, the structure of which includes a sand feeding bin 1, a frame 2, a sand screening device 3, a base 4, and a conveyor belt 5, the sand feeding bin 1 is fixed on the top of the frame 2, and the The frame 2 is installed on the base 4, the base 4 is connected to the conveyor belt 5, the sand screening device 3 is connected to the frame 2, and the sand screening device 3 includes a cylindrical screen 3a, an auger 3b, and a dredging mechanism 3c , a rotating shaft 3d, the inside of the cylindrical screen 3a is provided with a rotating shaft 3d, the rotating shaft 3d is connected with the auger 3b, and a dredging mechanism 3c is installed on the auger 3b.

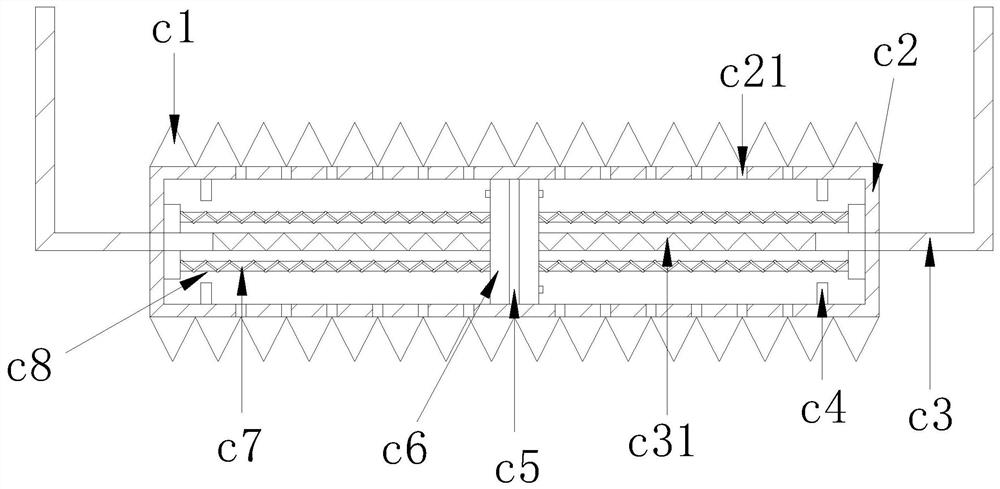

[0028] see Figure 3-4 , the dredging mechanism 3c includes a conical block c1, a mechanism body c2, a fixed rod c3, a buffer ring c4, a partition c5, a push plate c6, a tension spring c7, and a fixed telescopic rod c8, and th...

Embodiment 2

[0031] see Figure 1-2 , the present invention provides a sand screening machine for construction sites, the structure of which includes a sand feeding bin 1, a frame 2, a sand screening device 3, a base 4, and a conveyor belt 5, the sand feeding bin 1 is fixed on the top of the frame 2, and the The frame 2 is installed on the base 4, the base 4 is connected to the conveyor belt 5, the sand screening device 3 is connected to the frame 2, and the sand screening device 3 includes a cylindrical screen 3a, an auger 3b, and a dredging mechanism 3c , a rotating shaft 3d, the inside of the cylindrical screen 3a is provided with a rotating shaft 3d, the rotating shaft 3d is connected with the auger 3b, and a dredging mechanism 3c is installed on the auger 3b.

[0032] see Figure 3-4 , the dredging mechanism 3c includes a conical block c1, a mechanism body c2, a fixed rod c3, a buffer ring c4, a partition c5, a push plate c6, a tension spring c7, and a fixed telescopic rod c8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com