Diamond micro-powder multi-screen composite ultrasonic vibration screening device

A technology of diamond micropowder and screening device, which is applied in the directions of sieving, loading/unloading, transportation and packaging, can solve the problems of large accumulation thickness of diamond micropowder, high equipment operating cost, and inclination of screening equipment, so as to reduce equipment input cost and Equipment operation and maintenance costs, the effect of preventing screening efficiency and quality, and improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

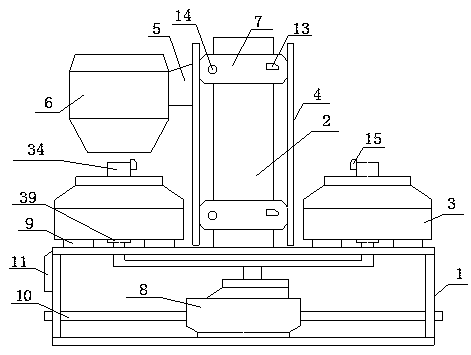

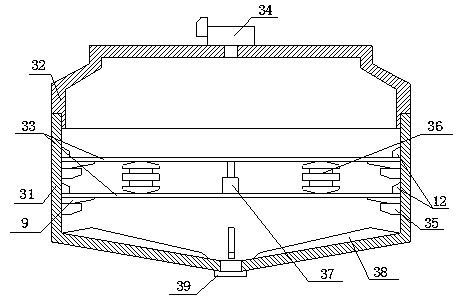

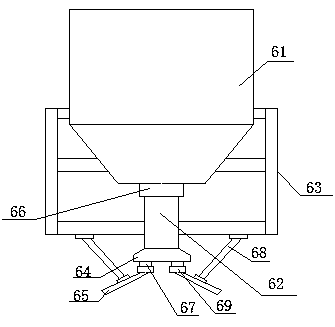

[0023] Such as figure 1 A kind of diamond micropowder multi-sieve composite ultrasonic vibration screening device described in -3 comprises a bearing base 1, a bearing column 2, a screening platform 3, a vertical guide rail 4, a lifting drive mechanism 5, a feeding mechanism 6, a turntable mechanism 7, Negative pressure fan 8, ultrasonic oscillation mechanism 9, discharge pipe 10 and control circuit 11, the bearing base 1 is a frame structure whose axis is perpendicular to the horizontal plane, and its upper end surface is connected to a bearing column 2 and at least two screening platforms 3 respectively , the bearing column 2 is coaxially distributed with the bearing base 1, the screening platform 3 is evenly distributed around the axis of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com