Bearing sealing cover shaping device

A shaping device and bearing sealing technology, which is applied in the field of bearing seal covers, can solve the problems of railway transportation safety hazards, bearing seal cover processing, and many bearings to be withdrawn.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in conjunction with specific embodiments. Obviously, the described embodiments are merely embodiments of the invention, not all of the embodiments. Based on the embodiments of the invention, all other embodiments obtained without creative labor have not made creative labor premises.

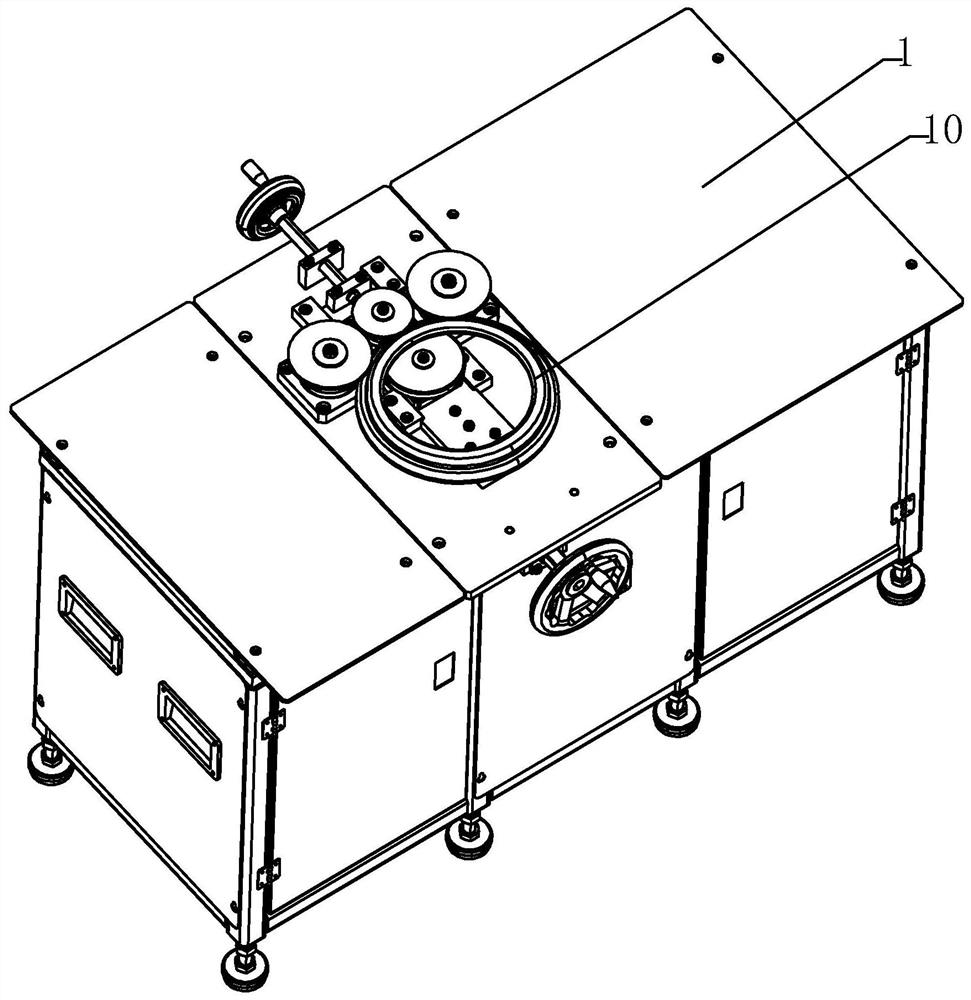

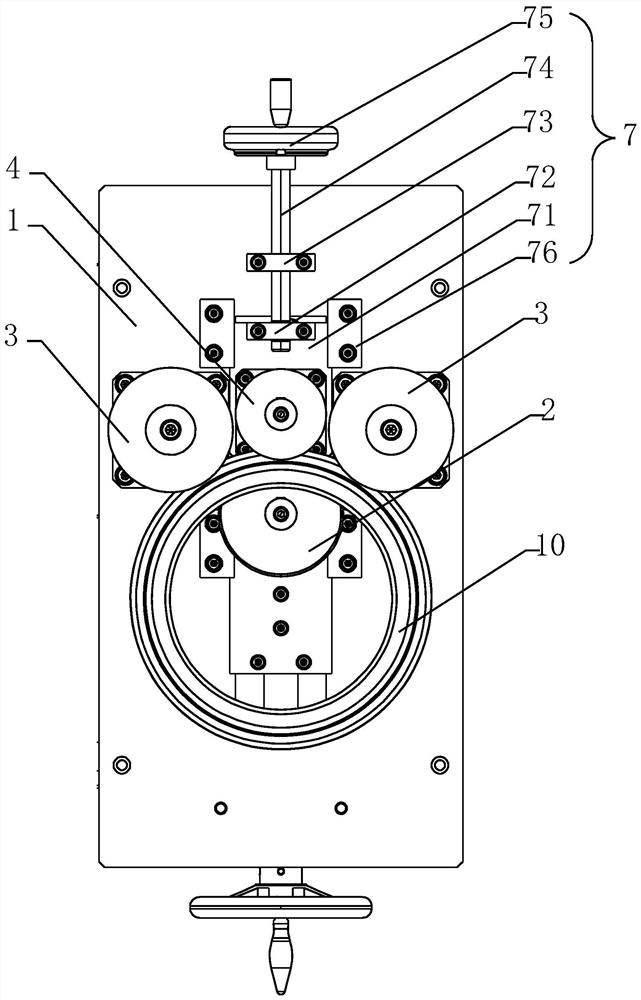

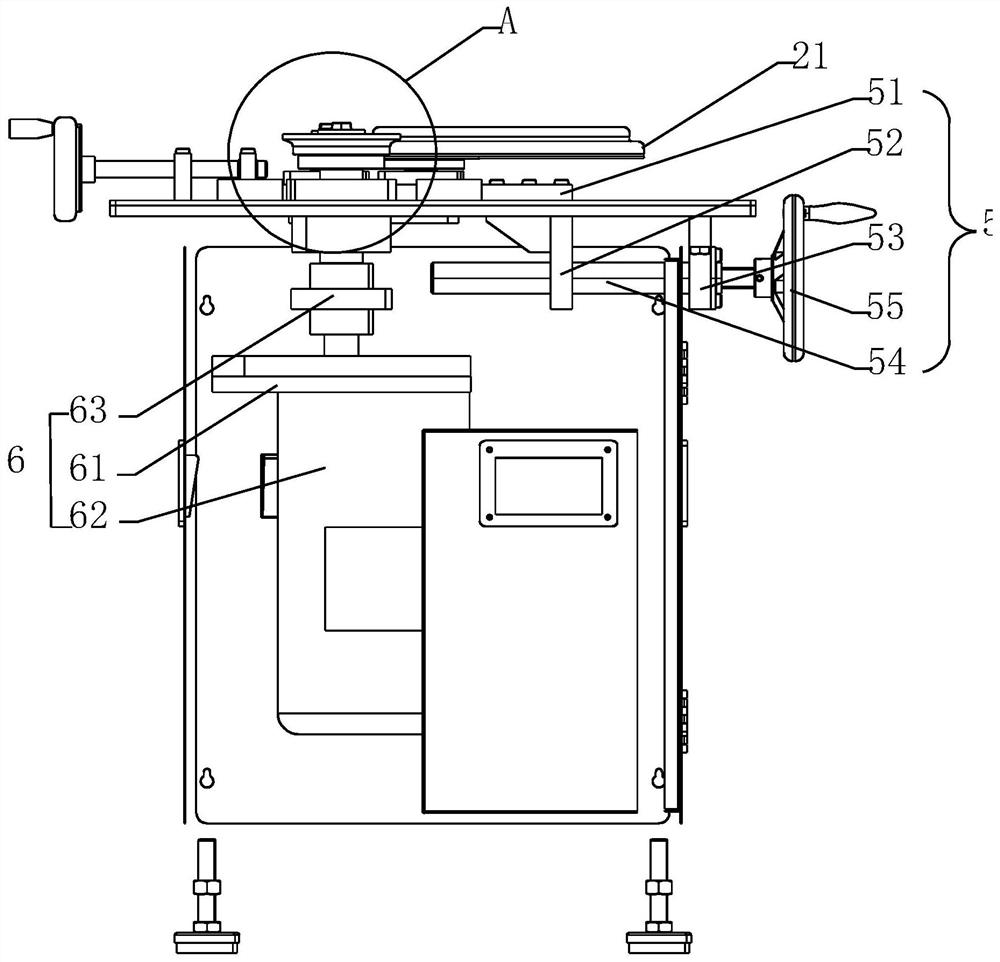

[0028] Embodiment, as figure 1 , figure 2 , Figure 4 As shown in a bearing housing shaped sealing means comprises a console 1, a rotation of the whole connected to the workstation of the positioning wheel 2, wheel 3 and two plastic disposed between two shaping rollers 3 console flat wheel 4, the upper end of the positioning wheel 2 is provided with a chamfered edge 21, a chamfered inner seal 21 and the cover 10 are bonded together, shaped wheel 3 includes an upper portion 31 sequentially from top to bottom, rounded corners 32, the lower end portion 33, the upper end portion 31 diameter of the lower portion of a diameter greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com