A kind of compression tube forming method

A technology for tube pressing and forming cavity, applied in the field of technology, can solve problems such as unevenness and uneven deformation of tube blanks, and achieve the effects of high shape accuracy, natural and smooth bending forming, and reducing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

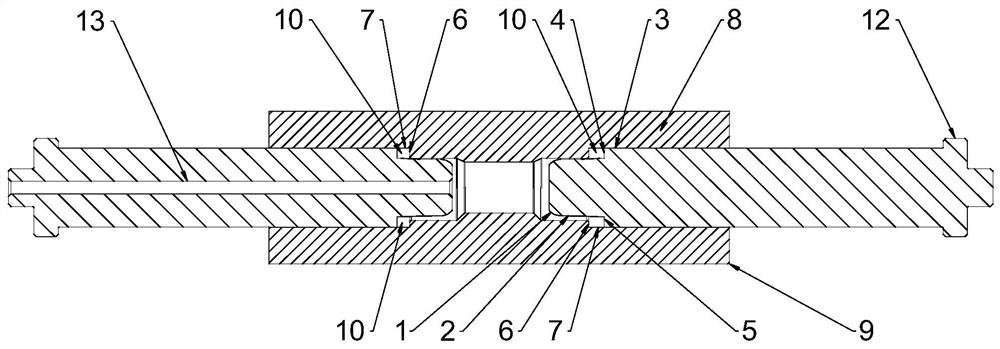

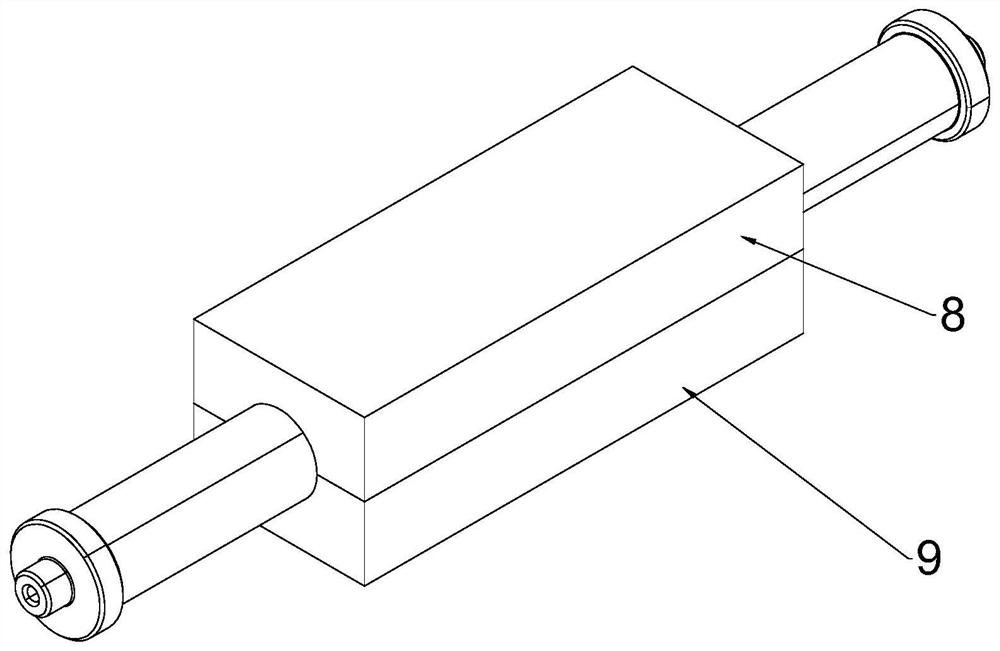

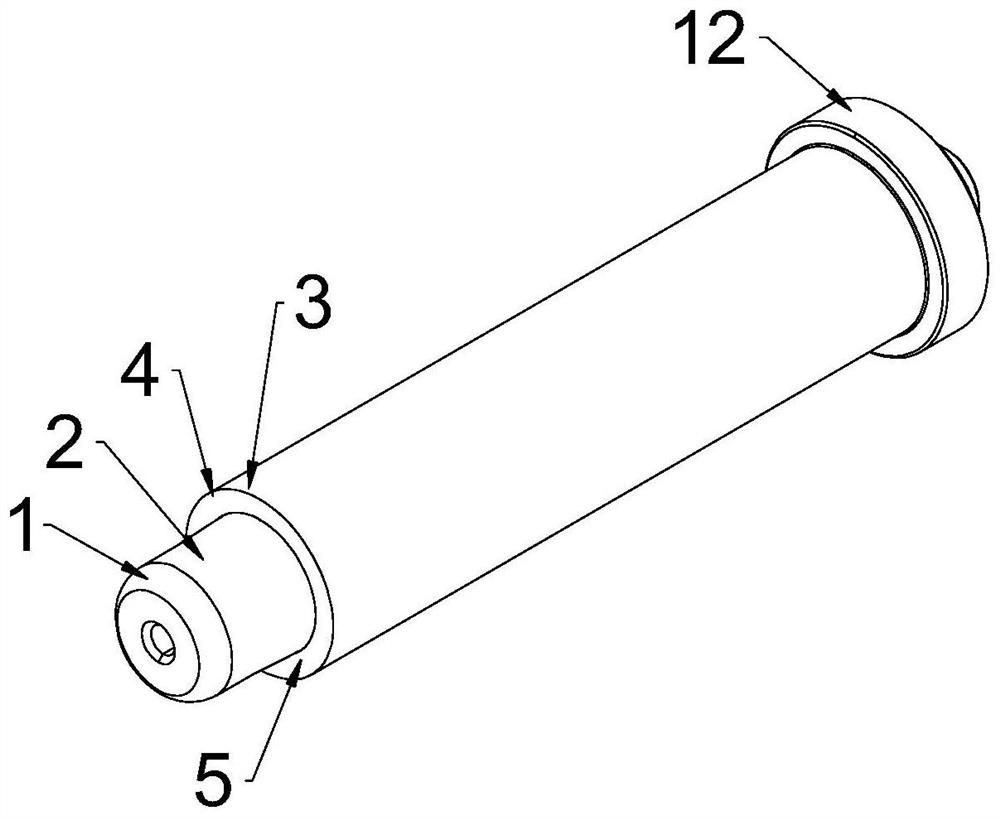

[0032] see Figure 1-Figure 3 , A compression tube forming device, comprising a mold and punches arranged on both sides of the mold, the mold is provided with a cavity matching the appearance of the compression tube, and the cavity includes a cavity for forming a compression tube. The forming part of the sealed tube body; the punch includes a flared section 1 for easy entry into the tube blank, a low-pressure sealing section 2 for low-pressure pre-expansion of the tube blank, and a high-pressure expansion type for the tube blank. The high-pressure sealing section 5 and the annular body 3 connected with the high-pressure sealing end; the high-pressure sealing section 5 includes a forming surface 4, and the forming surface 4 is located at the front end of the annular body 3, and is characterized in that the forming surface 4 is connected with the forming surface 4. The part forms a rectangular molding cavity 10 .

[0033] see Figure 1-Figure 3 , the forming part includes a ra...

Embodiment 2

[0042] see Figure 4-Figure 5 The difference between this embodiment and Embodiment 1 is that an annular accommodating groove 11 for accommodating the end of the tube blank is formed between the low-pressure sealing section 2 and the high-pressure sealing section 5, and the annular body 3 corresponds to the annular accommodating groove 11. The groove 11 surrounds the low-pressure sealing section 2 , and the forming surface 4 is arranged at the front end of the annular body 3 . The annular accommodating groove 11 of the above structure is provided. When forming the double-clamping tube, the end of the tube blank is embedded in the annular accommodating groove 11 and abuts the bottom of the annular accommodating groove 11. Since the forming surface 4 is located at the front end of the annular body 3, After the forming surface 4 is in place, there is a distance between the end of the tube blank and the annular circular arc cavity, so there is a distance between the forming positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com