Multi-working-condition adjustable vertical vortex ventilation testing device

A test device and multi-working-condition technology, applied in the field of ventilation, can solve problems such as the inability of pollution sources to simulate high-temperature pollutants, low flexibility, and difficult adjustment of working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

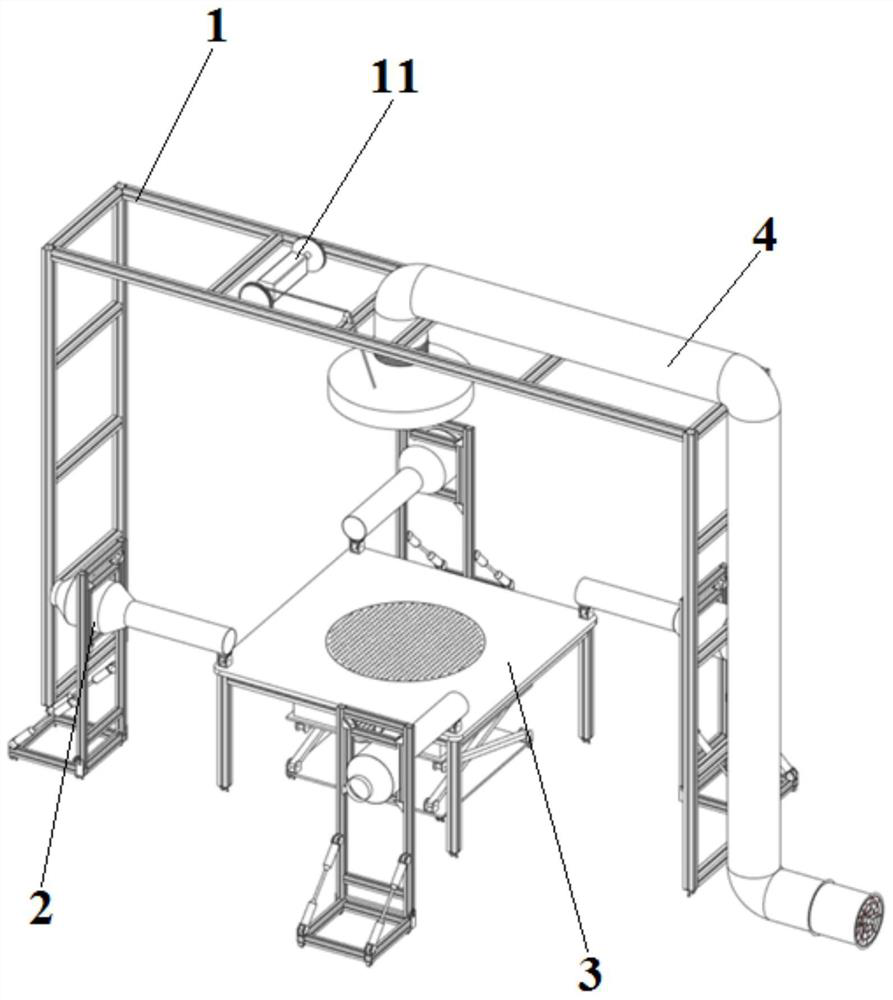

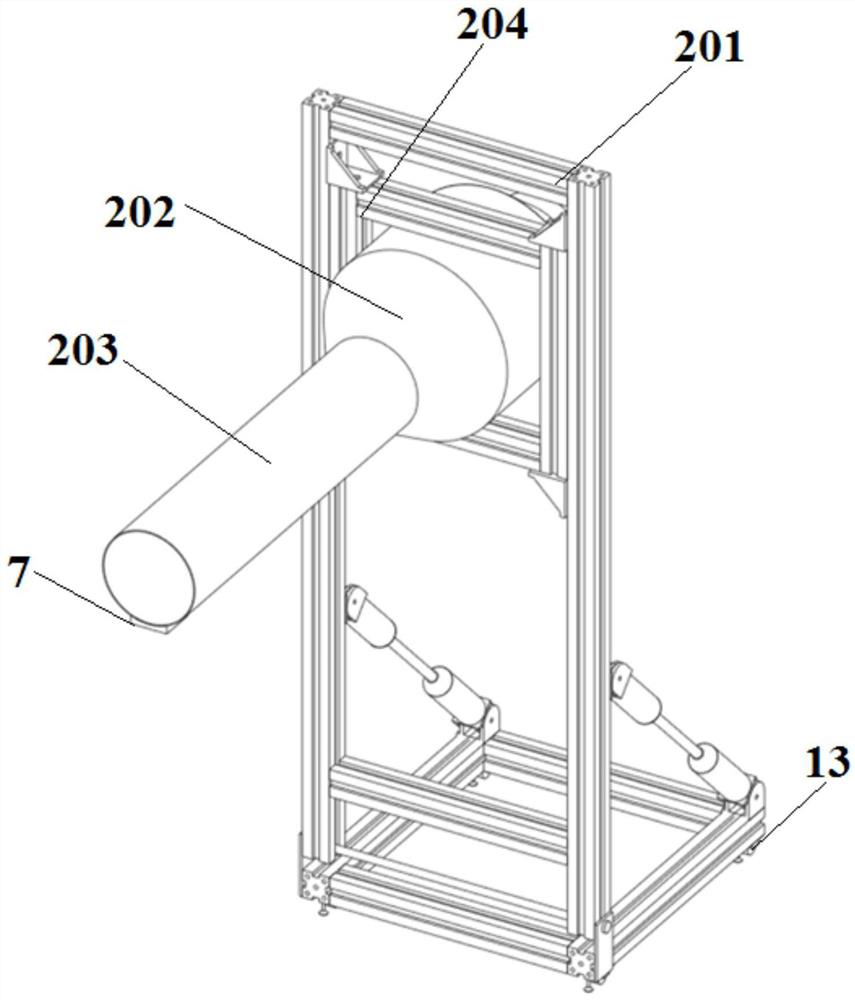

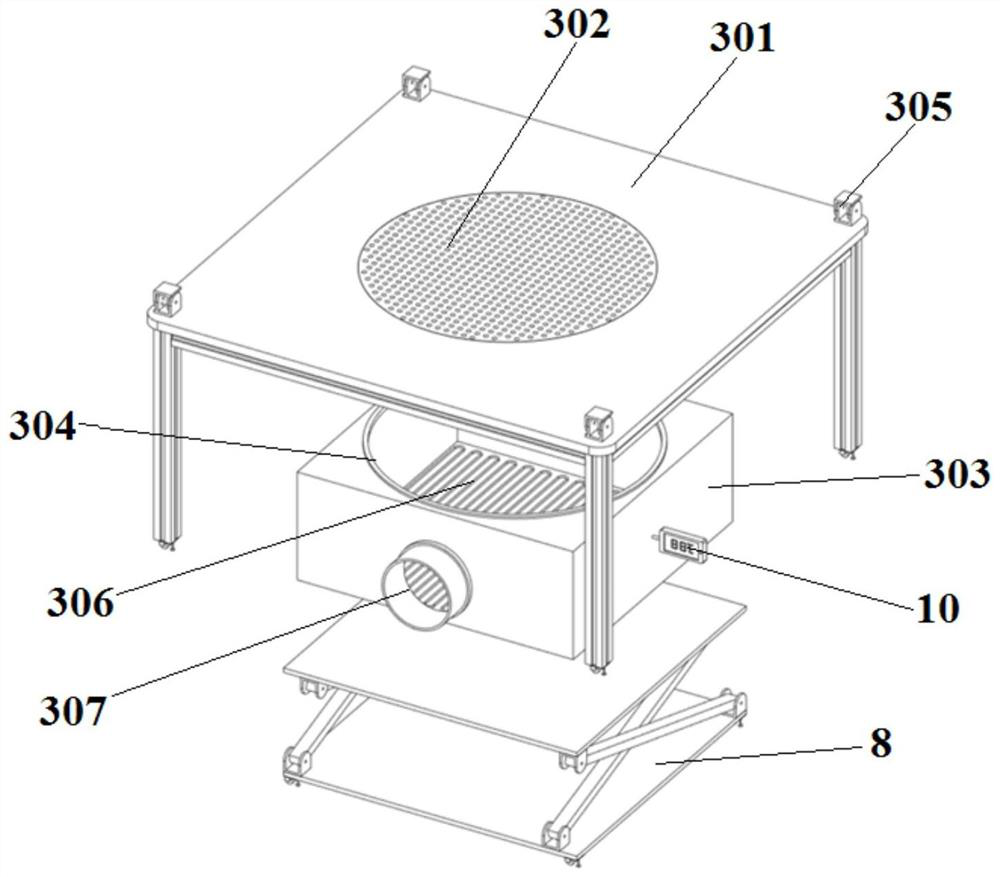

[0041] This embodiment provides a multi-working condition adjustable vertical vortex ventilation test device, such as Figure 1 to Figure 7 As shown, it includes an exhaust support frame 1, and also includes a plurality of air supply mechanisms 2, pollution source item modules 3 and exhaust mechanism 4. The exhaust mechanism 4 is detachably installed on the exhaust support frame 1, and the described air supply The wind mechanism 2 and the pollution source item module 3 are arranged inside the exhaust support frame 1, and are located directly below the exhaust outlet of the exhaust mechanism 4;

[0042] The multiple air supply mechanisms 2 are movable and evenly arranged around the pollution source item module 3, and the multiple air supply mechanisms 2 are all hinged with the pollution source item module 3;

[0043] The pollution source item module 3 is used to simulate pollution sources at different temperatures.

[0044] In the above-mentioned technical solution, there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com