A curved surface defect detection tool for engineering machinery cover parts

A technology for engineering machinery and defect detection, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as low detection efficiency and oilstone drop damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

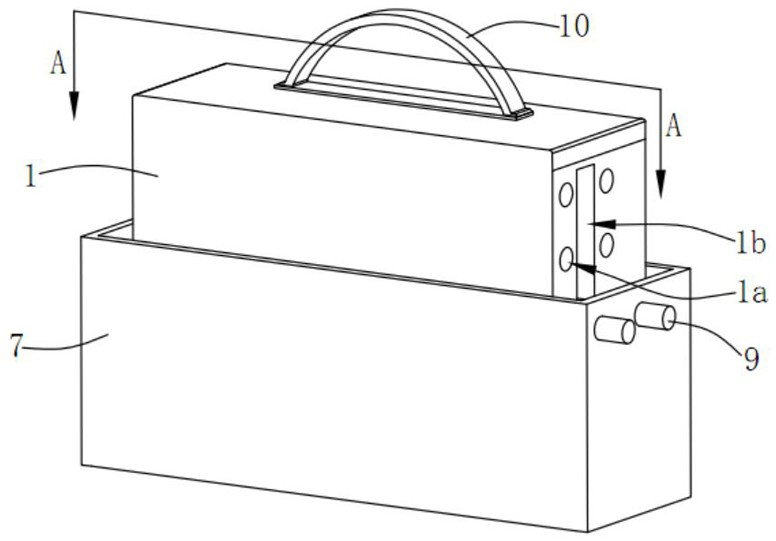

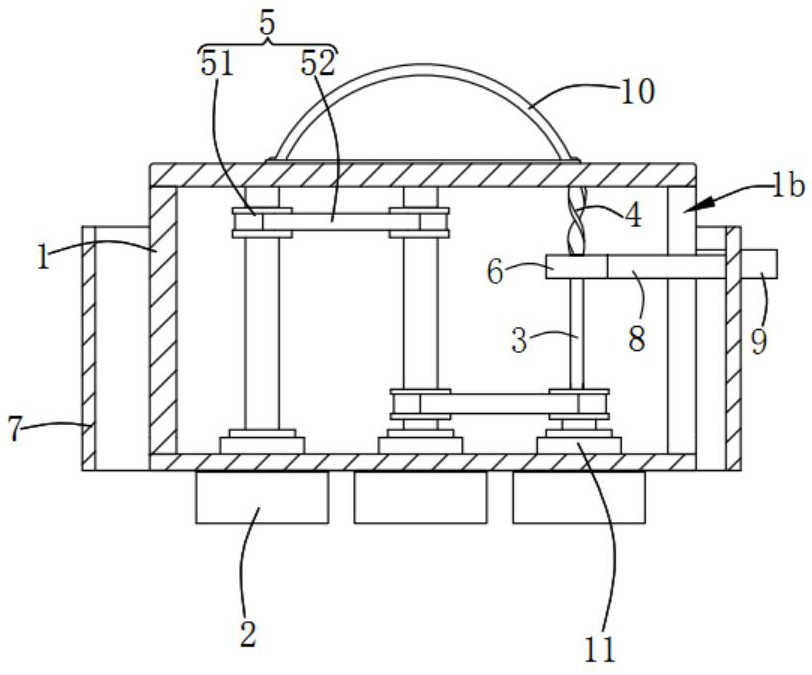

[0042] Please refer to Figure 1 to Figure 7 , in the first embodiment of the present invention, the curved surface defect detection tool for construction machinery covers includes a detection box 1 and a whetstone assembly 2, and the whetstone assembly 2 is horizontally attached to the bottom end of the detection box 1, and also includes a rotating Rod 3, spiral thread structure 4, transmission member 5, drive collar 6, protective frame 7, drive rod 8 and limiter 9;

[0043]The number of the oilstone assembly 2 and the rotating rod 3 are multiple, and the two are set in one-to-one correspondence; the rotating rod 3 is installed in the detection box 1, and one end of any one of the rotating rods 3 passes through After the detection box 1, it is fixedly connected with the corresponding one of the oilstone components 2, and the transmission connection between two adjacent rotating rods 3 is through the transmission member 5; wherein, the other of at least one of the rotating rod...

no. 2 example

[0074] Please refer to Figure 8 to Figure 9 , based on the curved surface defect detection tool for construction machinery covers provided by the first embodiment of the present invention, the second embodiment of the present invention provides another curved surface defect detection tool for construction machinery covers, the difference is that The curved surface defect detection tool for the construction machinery cover also includes a plurality of driven rods 13, the driven rods 13 pass through the detection box 1 and are rotatably connected with the other end of the corresponding one of the rotating rods 3, the One end of the driven rod 13 away from the rotating rod 3 is provided with a pointer 12 .

[0075] A preferred method of using the curved surface defect detection tool for construction machinery covers provided in this embodiment is as follows:

[0076] When the curved surface defect detection tool of the engineering machinery cover is in the first detection state...

no. 3 example

[0079] Please refer to Figure 10 to Figure 11 , based on the curved surface defect detection tool for construction machinery covers provided by the second embodiment of the present invention, the third embodiment of the present invention provides another curved surface defect detection tool for construction machinery covers, the difference is that The curved surface defect detection tool for the construction machinery cover part further includes a fixing part 14, and the fixing part 14 is detachably connected with any one of the driven rods 13 to limit the rotation of the driven rod 13.

[0080] In this embodiment, the fixing member 14 may include a fixing bracket and a fixing rod, the fixing bracket is fixed on the top of the detection box 1, and the fixing rod penetrates and connects the fixing bracket and any one of the transmission rods. .

[0081] A preferred method of using the curved surface defect detection tool for construction machinery covers provided in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com