Wide-working-distance large-aperture wide-angle TOF lens

A technology of working distance and aperture, applied in the field of optical lens, can solve the problems of low illumination, small field of view, small depth of field of large aperture lens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

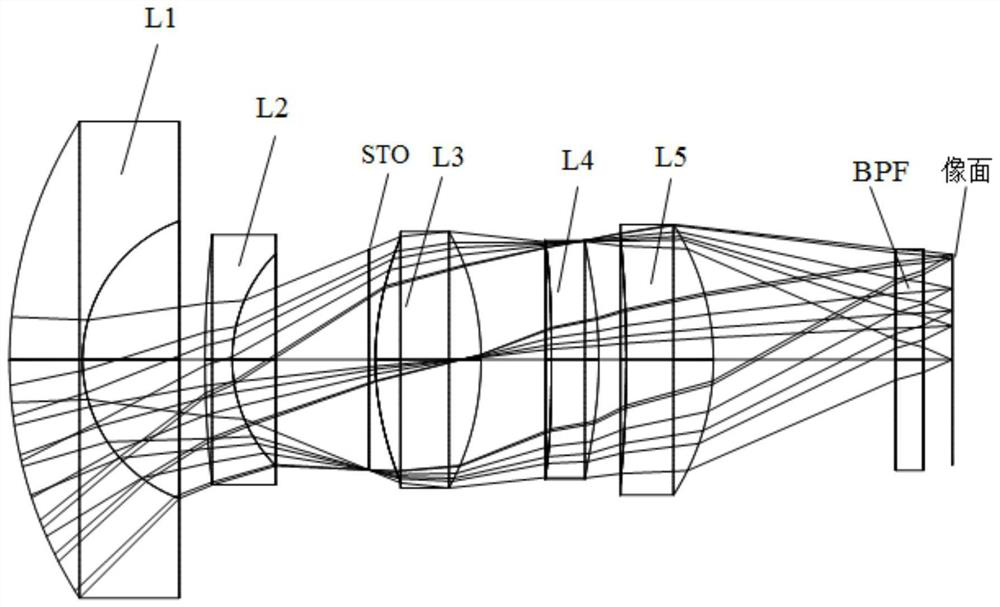

[0054] like figure 1 As shown, five 2GM3G all-glass lenses are used, the first lens L1 is a meniscus glass spherical lens with negative refractive power, the second lens L2 is a meniscus glass spherical lens with negative refractive power, and the third lens L3 is a positive refractive power. The fourth lens L4 is a meniscus molded glass aspheric lens with positive refractive power, and the fifth lens L5 is a meniscus glass spherical lens with positive refractive power.

[0055] In this embodiment, the wide working distance, large aperture, wide-angle TOF lens satisfies Table 1:

[0056] Table 1

[0057] Focal length / mm Material f1 -8.4297 H-LAF50B f2 -7.9033 H-BAK6 f3 8.0729 D-FK61 f4 21.6823 D-ZLAF85A f5 10.0952 H-ZPK5

[0058] The aspheric coefficients satisfy the following equations:

[0059]

[0060] Among them, z is the sagittal height of the aspheric surface, c is the paraxial curvature of the aspheric surface, ...

Embodiment 2

[0070] like figure 1 As shown, five 2GM3G all-glass lenses are used, the first lens L1 is a meniscus glass spherical lens with negative refractive power, the second lens L2 is a meniscus glass spherical lens with negative refractive power, and the third lens L3 is a positive refractive power. The fourth lens L4 is a meniscus molded glass aspheric lens with positive refractive power, and the fifth lens L5 is a meniscus glass spherical lens with positive refractive power.

[0071] In this embodiment, the wide working distance, large aperture, wide-angle TOF lens satisfies Table 4:

[0072] Table 4

[0073] Focal length / mm Material f1 -9.0052 TAF5 f2 -8.0622 H-ZK50 f3 8.1595 M-FCD500 f4 29.4805 M-FDS2 f5 9.9846 H-ZPK5

[0074] The aspheric coefficients satisfy the following equations:

[0075]

[0076] Among them, z is the sagittal height of the aspheric surface, c is the paraxial curvature of the aspheric surface, y is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com