Vision-based multi-stage precise landing method for unmanned aerial vehicle hangar

A technology of drones and hangars, which is applied in non-electric variable control, instruments, height or depth control, etc., and can solve problems such as large area of marked images, scale drift of drones, and failure of cameras to collect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

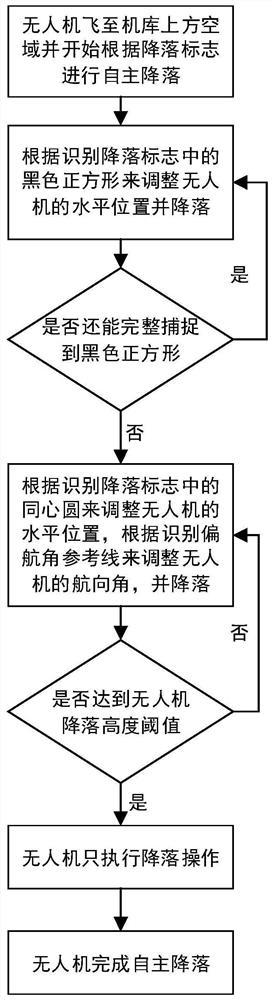

[0032] A vision-based multi-stage precise landing method for UAV hangars proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] Embodiments of the present invention and its implementation process are as follows:

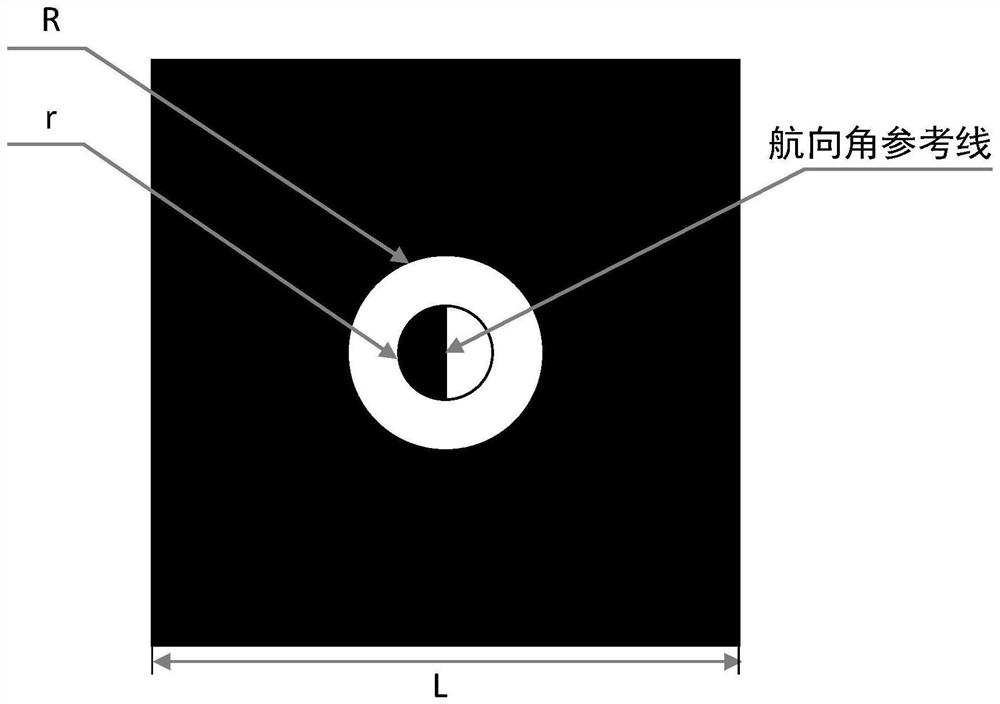

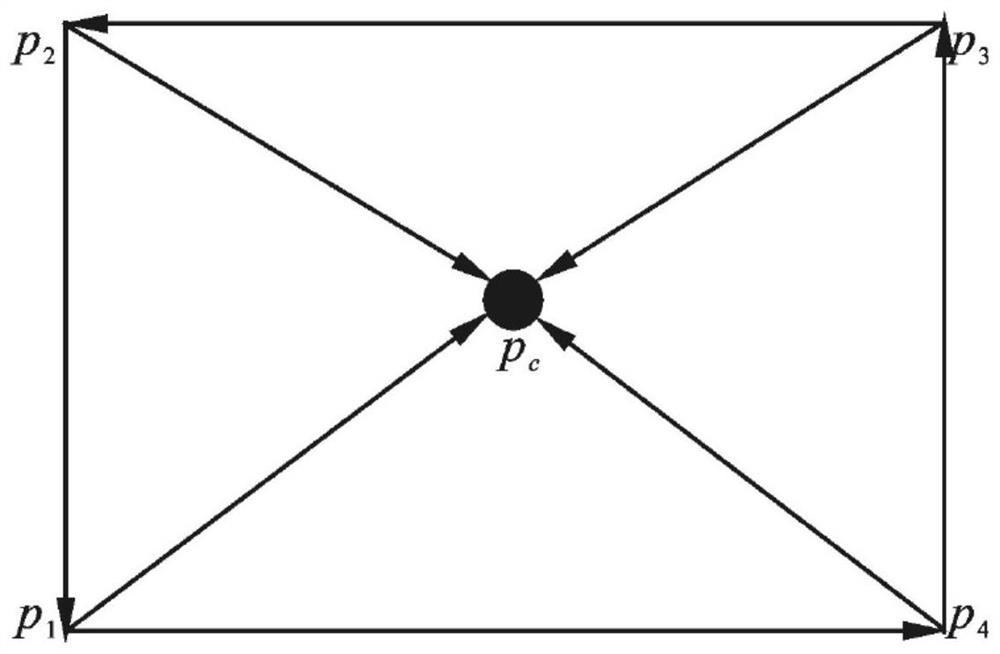

[0034] A drone hangar landing sign is designed and constructed. The drone hangar landing sign is mainly composed of a square and two concentric circles. The two concentric circles are arranged in the center of the square and concentrically arranged. The diameter of the two concentric circles The size is different, the smaller concentric circle is divided into two semicircles; the coloring of the two semicircles is different, the coloring of one semicircle is the same as that of the ring between the two concentric circles, and the coloring of the other semicircle is the same as that of the square.

[0035] In the specific implementation, the coloring of the two semicircles is divided by black...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com