Insulator and electric connector

A technology for insulators and joints, applied to insulators, fixed/insulated contact members, etc., to solve the problems of deformation and warpage of "slender" insulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

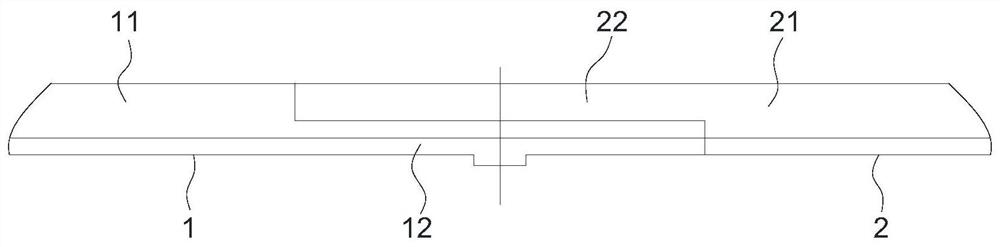

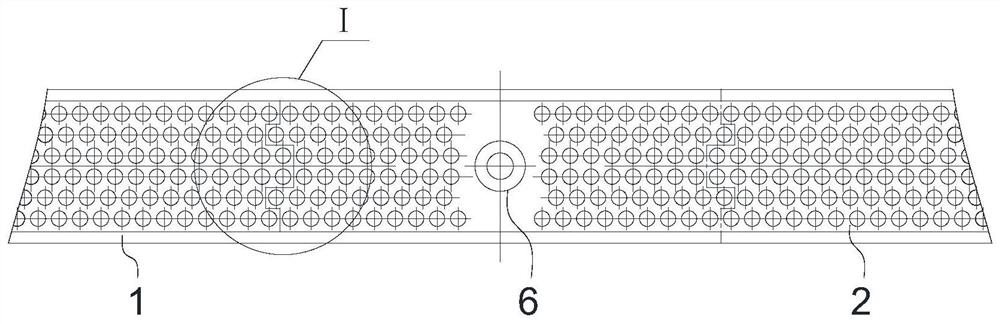

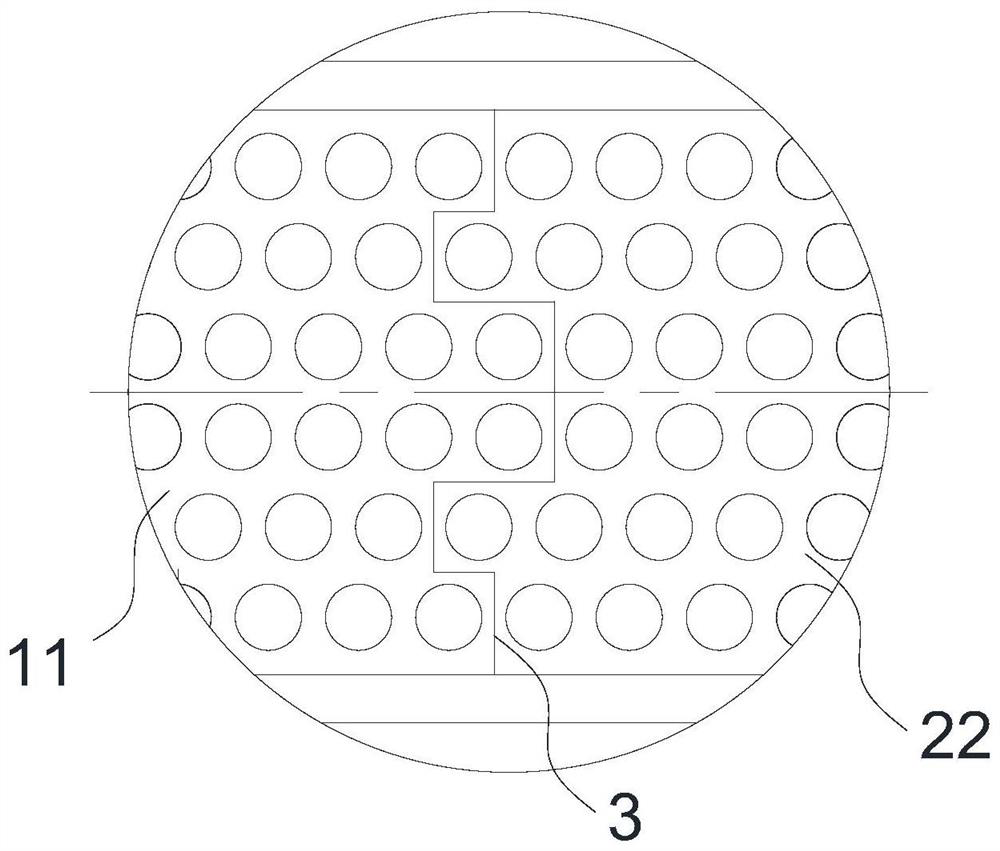

[0039] Such as Figure 1 to Figure 7 As shown, the overall length-to-width ratio of the insulator is 15:1, and the insulator is formed by lapping two parts of the first base 1 and the second base 2 in the middle. The first base 1 includes a first body 11 and an outer shell. The second base 2 includes a second body 21 and an outstretched second wing 22. The first wing 12 and the second wing 22 overlap and overlap each other along the abutting direction. And apply adhesive on all the overlapping interfaces of the first base 1 and the second base 2 to form the insulator as a whole. For an insulator with a larger aspect ratio, the number of overlapping bases can be appropriately increased to ensure the processing quality of a single base and the overall quality.

[0040] The connection between the end surface of the first protruding wing 12 and the second body 21 , and the connection between the end surface of the second protruding wing 22 and the first body 11 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com