Tangential functionally gradient coating transition region design and performance prediction method based on track width and track distance constraints

A technology of functional gradient and design method, applied in coating, design optimization/simulation, metal material coating process, etc., can solve the problem of uneven transition of erosion resistance, unstable transition of erosion resistance, and stress concentration in the transition zone. and other problems, to achieve the effect of easy promotion, simple prediction method, smooth transition and prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Taking a certain type of blade (substrate material is FV520B) eroded and worn by gas-solid two-phase flow as an example, the surface was prepared with Cr 3 C 2 -NiCr coating (where "Cr 3 C 2 " is a brittle ceramic material, "NiCr" is a tough metal material, and the mass ratio of "NiCr" in the composite coating is the design method of the compound ratio), which specifically includes the following steps:

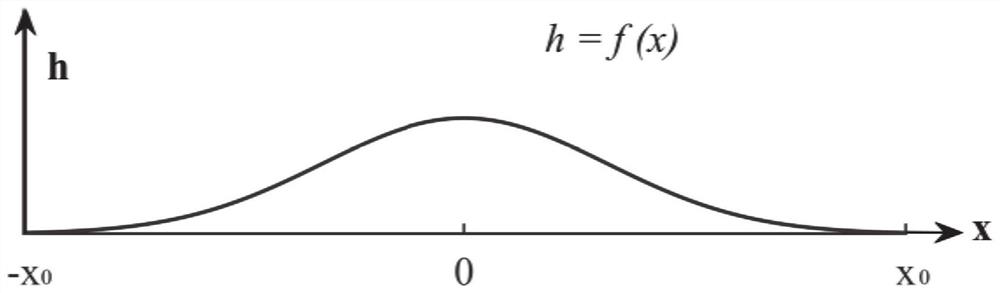

[0043] Step 1: Intercept the section of a single sprayed coating, use the image recognition tool to extract the height value of the coating profile, and fit the coating profile function. Among them, h=f(x) is the coating growth rate distribution function, that is, the track width is 2x 0 ,Such as figure 1 shown.

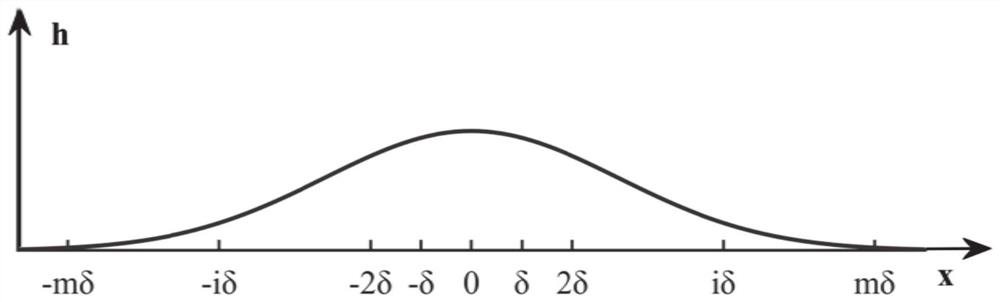

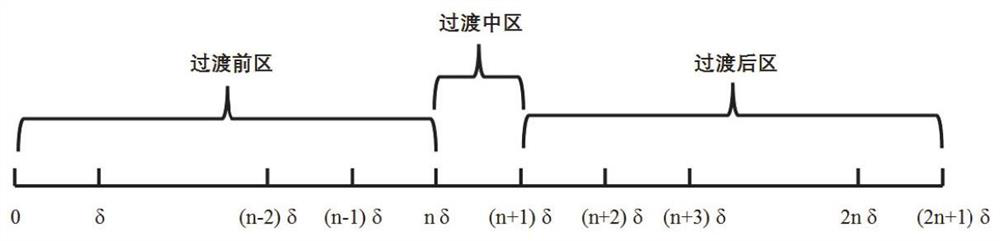

[0044] Step 2: In order to ensure that each transition area on the sprayed surface follows a consistent transition law, based on the constraints of the road width and distance, the road width is selected to be 2m times the road distance, and the road dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com