Balanced type assembling machine for T-shaped suspension support assembly

A technology for hanging brackets and assembling machines, which is applied to metal processing equipment, metal processing, manufacturing tools, etc., and can solve problems such as low precision and slow manual operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

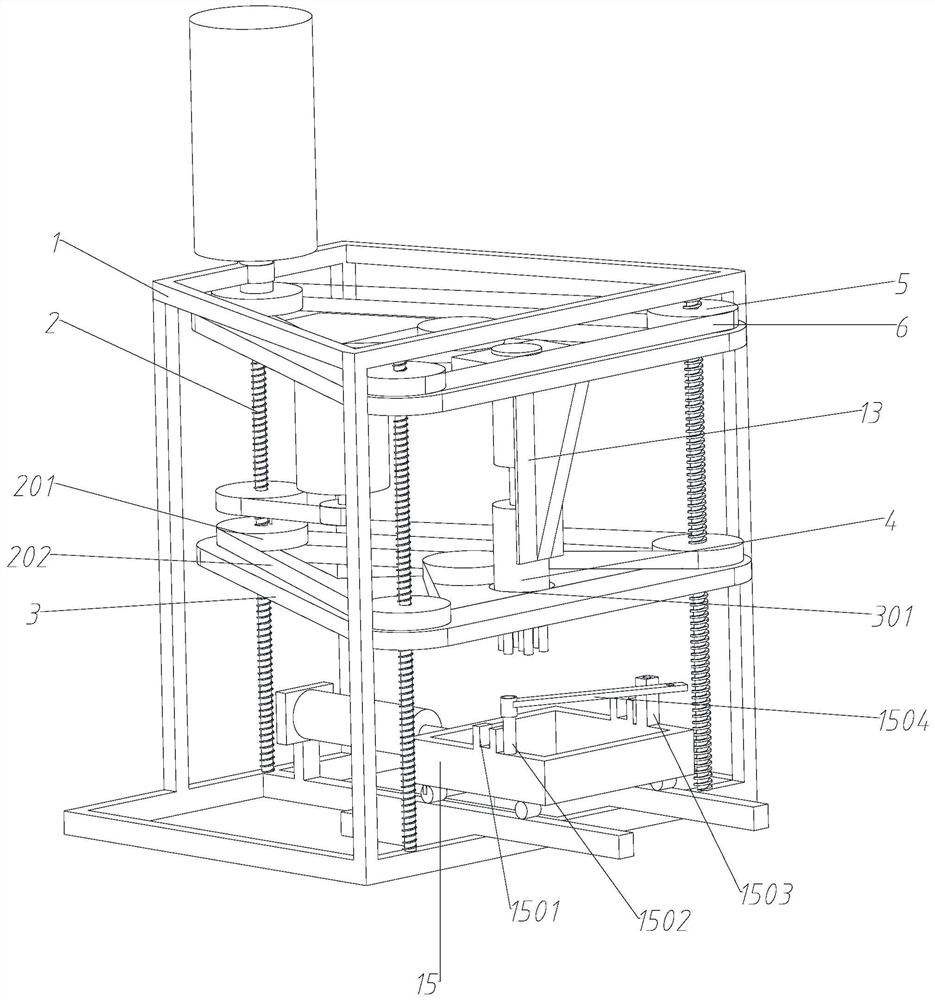

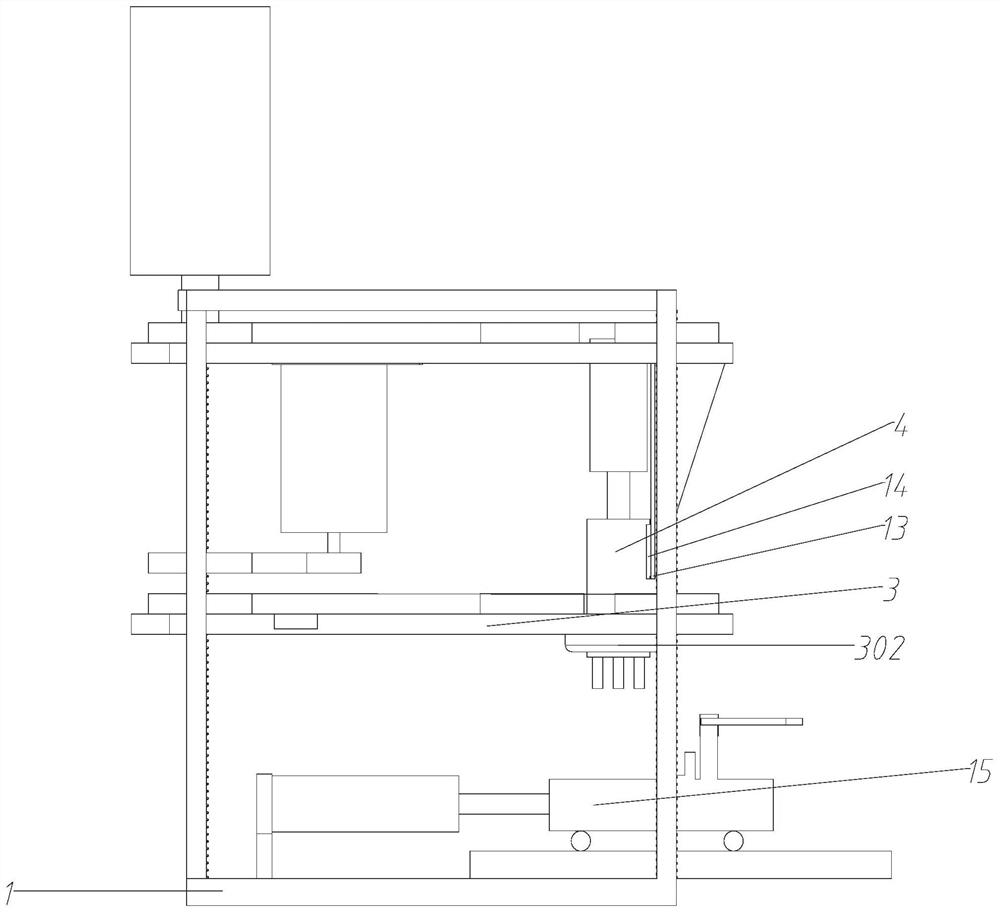

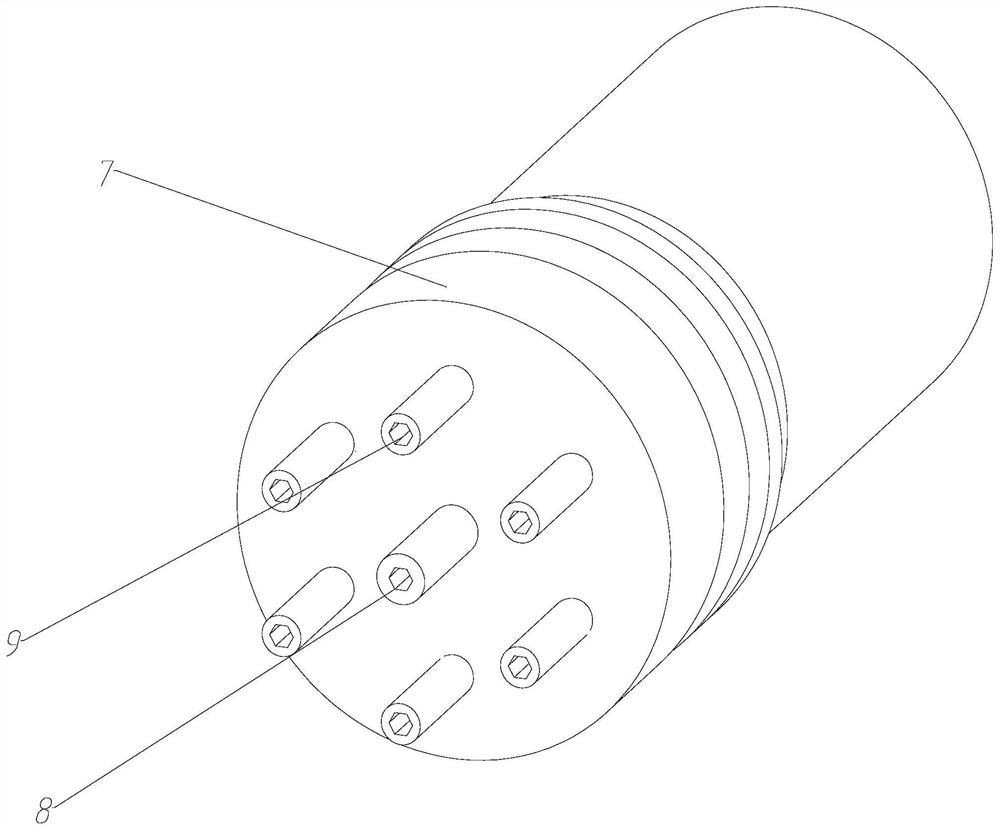

[0052] Such as Figure 1 to Figure 6 As shown, this embodiment proposes a T-shaped suspension bracket assembly balanced assembly machine, including:

[0053] Frame 1, the frame 1 has a processing position, the workpiece is placed on the processing position for processing,

[0054] guide rod 2, the guide rod 2 is vertically arranged on the frame 1,

[0055] A pressing member 3, the pressing member 3 is moved and arranged on the guide rod 2, and moves along the guide rod 2, and the pressing member 3 has,

[0056] A circular hole 301, the circular hole 301 is located above the processing position,

[0057] a press table 302, the press table 302 is arranged at the circumferential position of the circular hole 301, and is used to press the workpiece,

[0058] The pretensioning member 4 is movably arranged on the frame 1 , the pretensioning member 4 is located above the workpiece, moves vertically, and can pass through the circular hole 301 .

[0059]The installation and pretigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com