Connecting structure of combined type valve

A connection structure, combined technology, applied in the field of hydraulic valves, can solve the problems of loosening, reducing sealing and reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

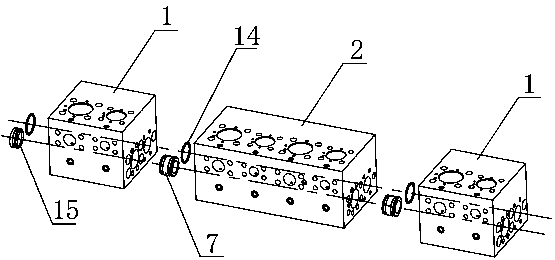

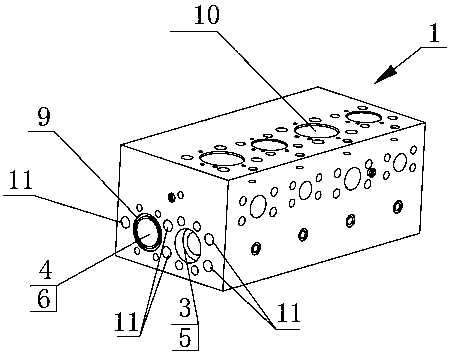

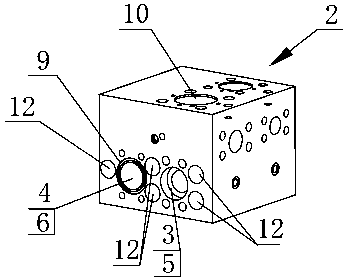

[0026] Such as figure 1 , figure 2 As shown, the basic valve block 1 is provided with an oil inlet pipe 3 and an oil return pipe 4 inside. The oil inlet pipe 3 and the oil return pipe 4 run through the body of the valve block, and an oil inlet pipe port 5 and an oil return pipe port 6 are formed on both ends of the valve block. The oil inlet pipe ports 5 on both sides are provided with step holes, the oil return pipe port 6 on one side of the basic valve block 1 is provided with a gasket groove 9, and the other side end surface is not provided with a gasket groove 9. The sealing ring 14 is arranged in the gasket groove 9 and is used for sealing the joint of the oil return pipe 6 . Several valve holes 10 are provided inside the basic valve block 1 for forming oil passages or installing cartridge valves. The cartridge valve is connected with the oil inlet pipe 3, the oil return pipe 4 and each pipeline forming the oil circuit, and controls each oil circuit to be connected or ...

Embodiment 2

[0033] In this embodiment, no thread is provided on the basic valve block 1, but a through hole is provided at this position. The threaded rods at both ends are used to pass through the through holes of the entire basic valve block 1 and the extended valve block 2, and nuts are used to lock the two ends of the rods, which can also meet the fastening requirements. Of course, long bolts can also be used, and the other end is locked with a nut.

Embodiment 3

[0035] Such as Figure 7 and Figure 8 As shown, the combined valve in Embodiment 1 is also provided with a transition block 16 that realizes the combined connection of the large-size valve block and the small-size valve block. The expansion valve block 2 is connected by a transition block 16. The transition block 16 is connected to the position and diameter of the oil inlet pipe 5 and the oil return pipe 6 at one end of the large-size valve block and the oil inlet pipe 5 of the large-size valve block. It is equivalent to the oil return pipe port 6; the other end is equivalent to the oil inlet pipe port 5 and the oil return pipe port 6 of the small size valve block, the two-way sealing joint 7 placed at the oil inlet pipe port 5, and the gasket groove 9 arranged at the oil return pipe port 6 , The sealing ring 14 is the same as the above embodiment. The inside of the transition block 16 realizes diameter reduction through stepped holes, tapered holes, staggered holes, etc., ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com