Express box

A technology of box body and box cover, which is applied to impact-sensitive items, rigid containers, closing and other directions, can solve the problems of unfavorable recycling and reuse, troublesome opening of box cover, occupation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

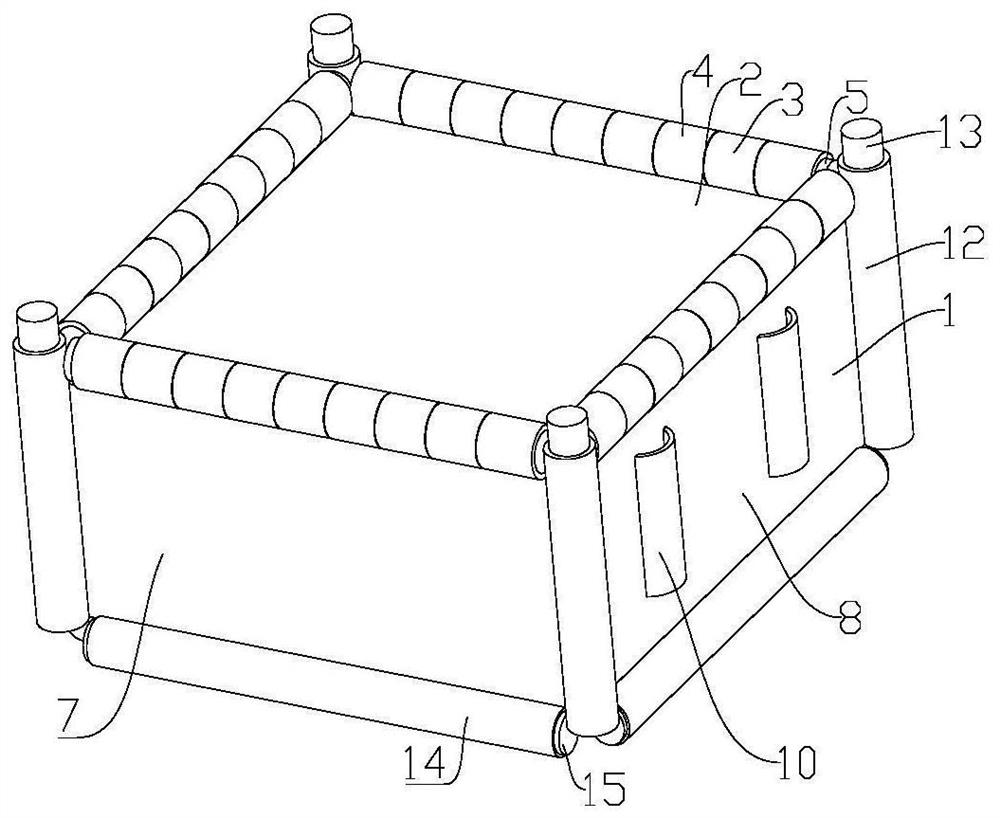

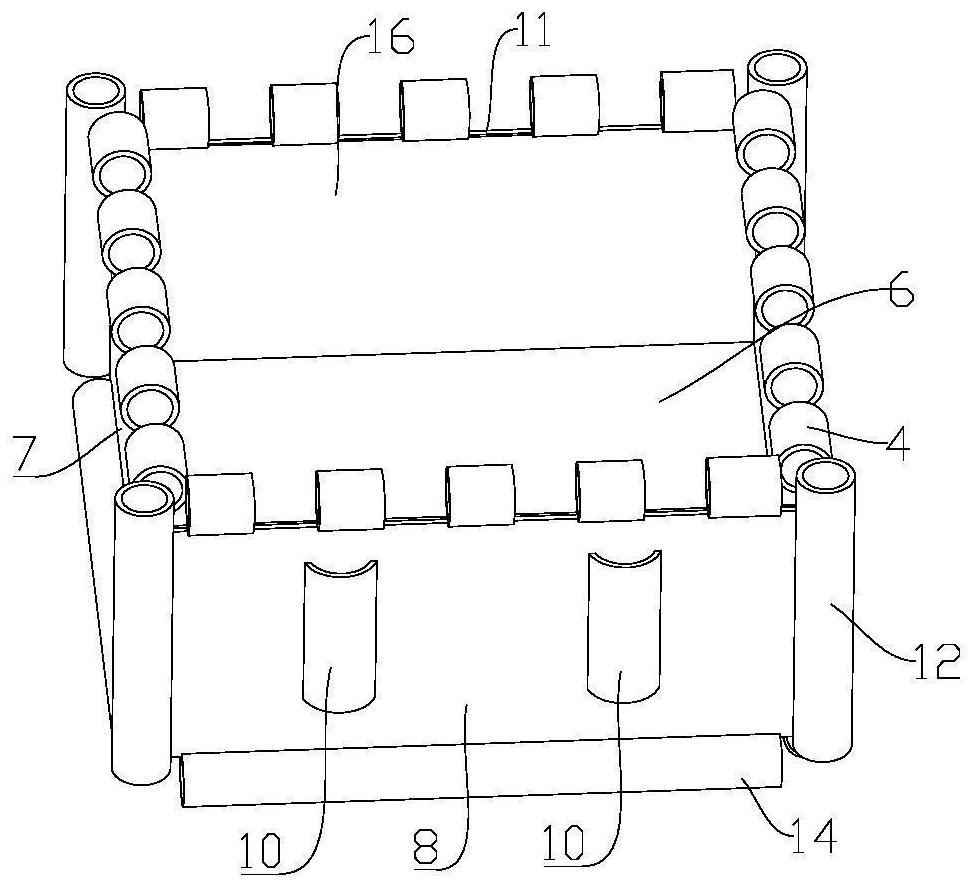

[0034] Such as Figure 1-5 As shown, the present embodiment provides a courier box, including a box body 1 and a box cover 2, at least one first sleeve 3 is provided on the side wall of the box cover 2, and at least one The second sleeve 4 matched with the first sleeve 3 further includes a connecting piece 5 movably threaded through the first sleeve 3 and the second sleeve 4 .

[0035]In this embodiment, at least one first bushing 3 is provided on the side wall of the box cover 2, and at least one second bushing 4 matched with the first bushing 3 is provided on the edge of the opening of the box body 1. The connecting piece 5 provided in the first sleeve 3 and the second sleeve 4; the first sleeve 3 on the box cover 2 and the second sleeve 4 on the box body 1 are interpenetrated and connected to each other, so that the box cover 2 is fixed on the box body 1 to seal the box body 1, so that the box cover 2 is easily installed on the box body 1, and then the connector 5 is inser...

Embodiment 2

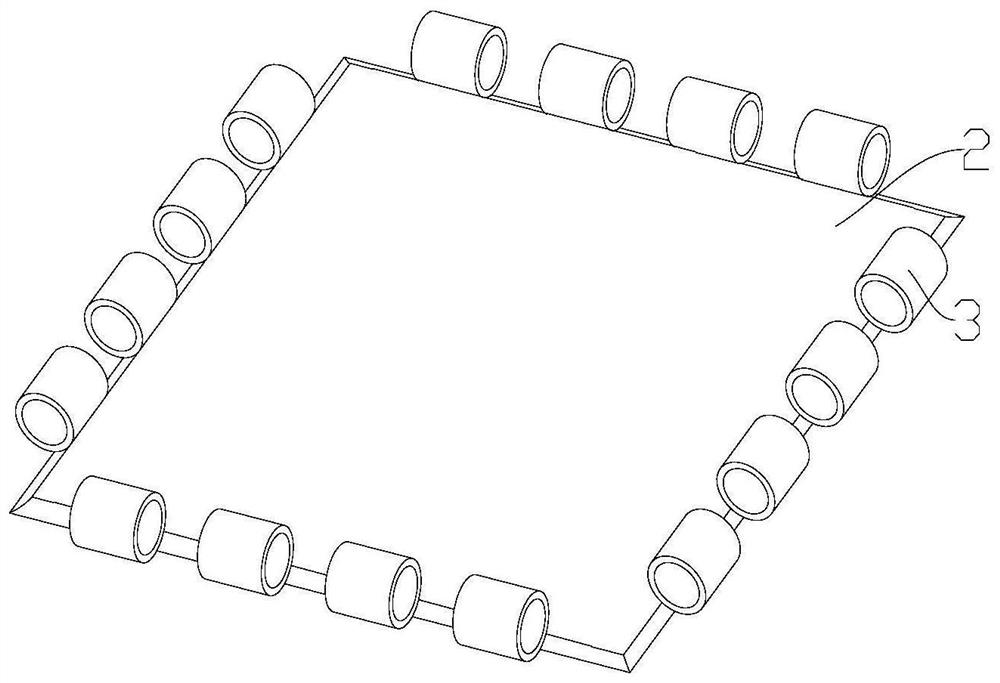

[0037] Such as Figure 1-5 As shown, in this embodiment, on the basis of Embodiment 1, a plurality of first sleeves 3 are provided on the side walls of the above-mentioned box cover 2, and a plurality of the above-mentioned first sleeves 3 are evenly distributed along the edge of the above-mentioned box cover 2. The opening edge of the body 1 is provided with a plurality of second sleeves 4 , and the plurality of second sleeves 4 are evenly distributed along the opening edge of the box body 1 .

[0038] In this embodiment, a plurality of first sleeves 3 are arranged on the side wall of the box cover 2, and the plurality of first sleeves 3 are evenly distributed along the edge of the box cover 2, and a plurality of second sleeves 3 are arranged on the edge of the opening of the box body 1. Sleeve 4, a plurality of second sleeves 4 are evenly distributed along the opening edge of the above-mentioned box body 1; 3 is interspersed with a plurality of second sleeves 4 on the upper...

Embodiment 3

[0042] Such as Figure 1-5 As shown, on the basis of some of the above-mentioned embodiments in this embodiment, the above-mentioned box body 1 includes a bottom plate 6 and two sets of symmetrical side plates 7, any one of the above-mentioned side plates 7 is connected to the above-mentioned bottom plate 6, and any two adjacent The side plates 7 are all connected, wherein a group of symmetrical side plates 7 are all made of elastic materials.

[0043] In this embodiment, one group of symmetrical side panels 7 above are all made of elastic material, and the elastic material can be bent, that is, the side panel 7 made of elastic material can be folded, and the other group of side panels 7 can be folded along the two elastic materials. The manufactured side panel 7 is symmetrically folded on the bottom panel 6, that is, the folding is completed. For those express boxes that need to use a folding structure, the manufacturing cost is simpler and lower, and the side panel 7 made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com