Quality label for textile product

A technology for displaying labels and fiber products, which is applied in the field of sewing labels for quality display, and can solve the problems of complex clothing manufacturing process, damage to the appearance of clothing, and failure to consider light transmittance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

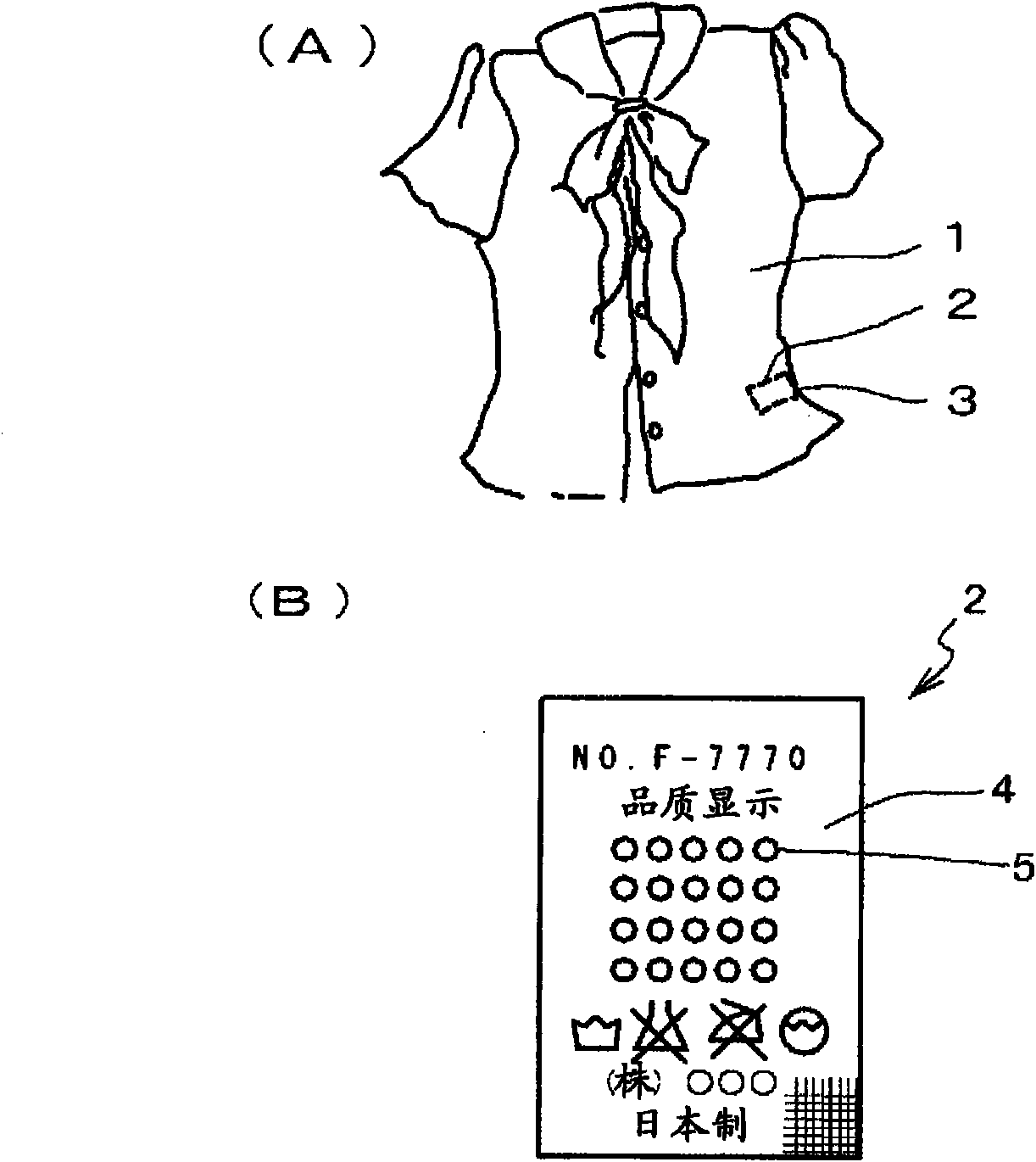

[0063] [Label Base Fabric( figure 2 )]

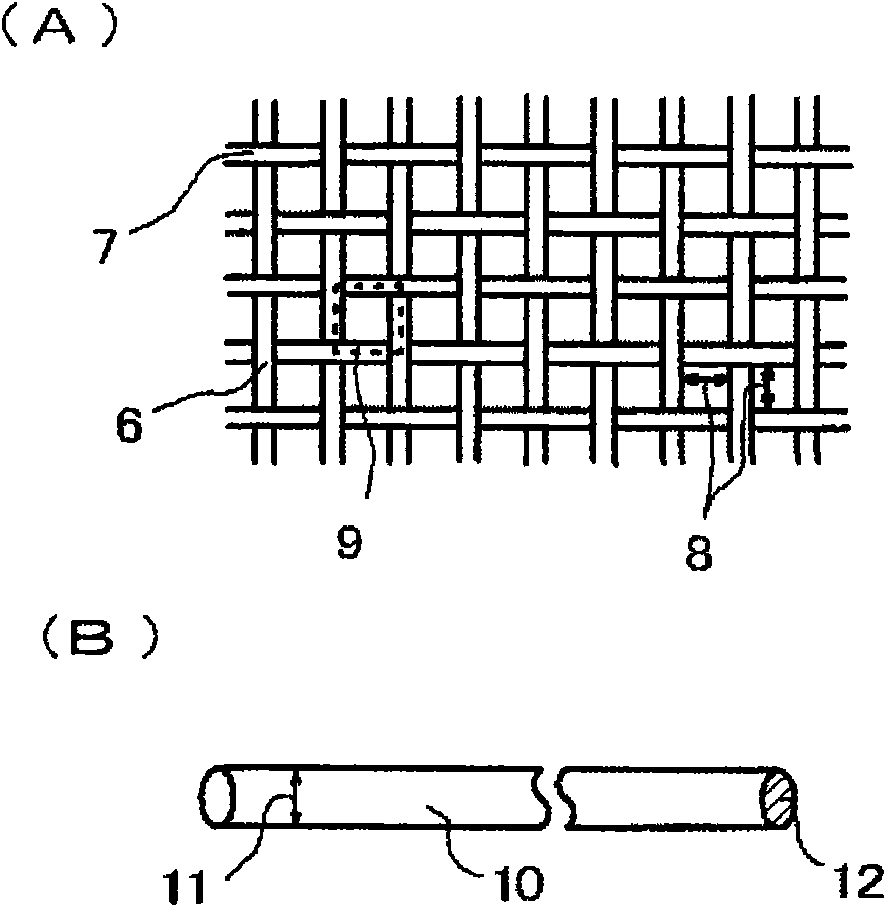

[0064] It is 100 * 90 / inch (warp 100 / inch, weft 90) to weave into fabric density by using warp yarn and weft yarn to be 26T yarns 6,7 of circular bright monofilament 10 and polyester untwisted yarn. root / inch) of plain weave.

[0065] At this time, the opening (the distance between the yarns), that is figure 2 The vertical and horizontal gaps shown by the symbol 8 in (A) were obtained by 25400 / mesh-wire diameter 11, and the result was 221 μm, and the opening area was 9 (void ratio) by (the distance between yarns) 2 / (distance between yarn and yarn + wire diameter) 2 Calculated, the result is 68%.

[0066] The total light transmittance of the base fabric was measured (measured at the wavelength of the visible light range of 380nm (nanometer) to 780nm) for the test light. As a result, a result of 99.2% or more was obtained, thereby obtaining a transparent fabric that is not considered to be a fabric. sense, the base fabric of the n...

example 2

[0074] Roll coating on 50-mesh gauze (25×50 cm) with a 65% opening area, 408 μm opening (gap) and 100 μm monofilament untwisted polyester yarn with a round cross-section. A transparent polyurethane resin (manufactured by Nippon Polyuretan Co., Ltd.) was applied, and then matting was performed on the surface of the film.

[0075] The total light transmittance is 92.4%.

[0076] Then, the thermal transfer tape D110A (ink) was thermally transfer printed with a printing machine manufactured by Oakbecking System Co., Ltd. .

[0077] Since the surface of the base cloth is a film layer, good fastness results can be obtained even if the existing method is used for printing.

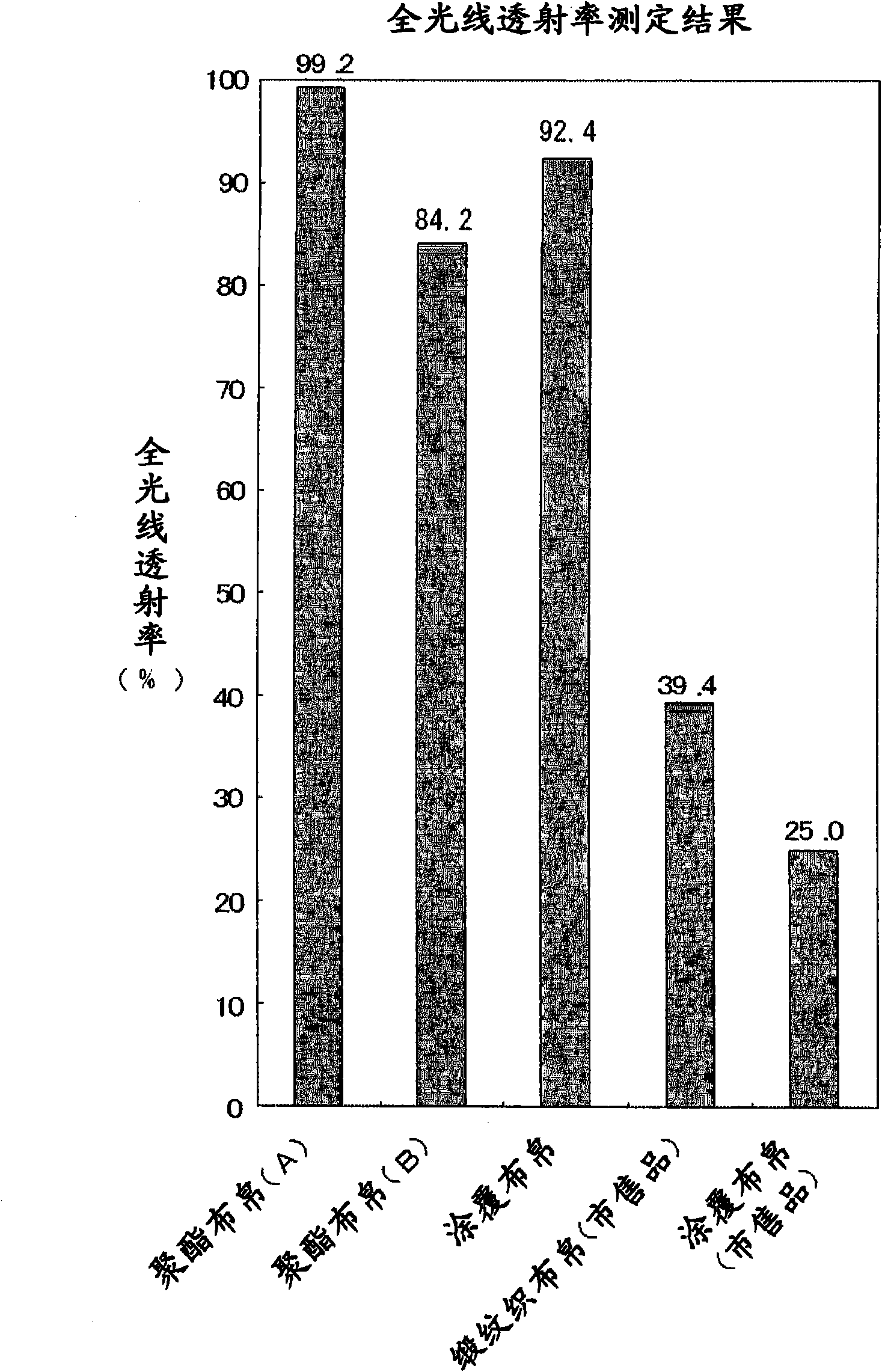

[0078] image 3It is an easy-to-understand graph that graphically displays the numerical values of the total light transmittance of various substrates. That is, as the substrate, (1) the polyester fabric (A) used as the base fabric of Example 1, (2) the polyester fabric (B) used, (3) the coated fabric used a...

example 3

[0080] If the base fabric 4 of the above-mentioned examples 1 and 2 is a base fabric with a parallel ray transmittance of 9% or more, a transparent sense of transparency not considered to be a fabric level, and a new field of air permeability and moisture permeability are obtained. base cloth. As a result, in the case of only the total light transmittance of 80% or more, the cloth type is only twice that of the existing product, and the film type is only about 3 times that of the existing product. Therefore, it is difficult to judge the see-through effect, but by newly combining the index of "parallel light transmittance of 9% or more", the gap increases to more than 4 times for the film type (coated fabric), and for the cloth type (satin weave fabric). It is 15 times (compared with the parallel light transmittance of polyester fabric (B) 49.3%) or more, so it has the following advantages: it is easy to grasp in detail the content of titanium dioxide in the fiber related to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com