Pre-judgment operation and maintenance planning method and terminal

A predictive and planning technology, applied in instrumentation, business, buying and selling/lease transactions, etc., can solve problems such as economic loss, user experience degradation, users unable to wash cars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

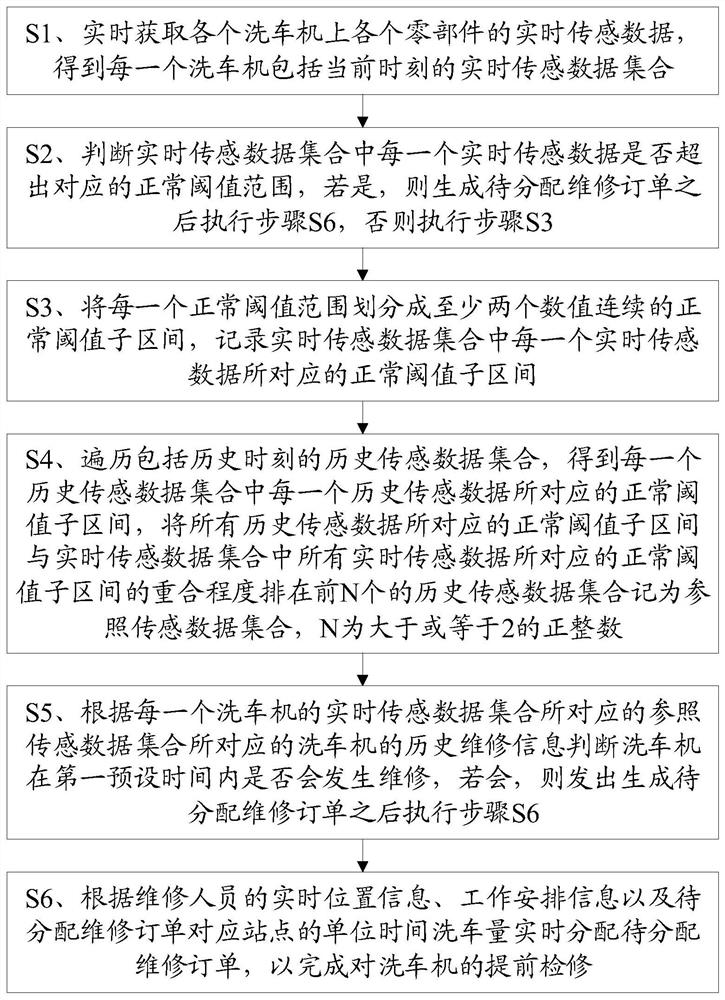

[0063] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0064] Predictive operation and maintenance planning method, including steps:

[0065] S1. Obtain the real-time sensing data of each component on each car washing machine in real time, and obtain the real-time sensing data set of each car washing machine including the current moment;

[0066] In this embodiment, the real-time sensing data is related data information of each component on the car washer, including temperature data, current data, voltage data or vibration data, etc. The required detection information can be collected according to the corresponding settings.

[0067] Among them, the sensor of each component on each car washing machine will carry unique identification information to prove itself when sending sensing data. According to these unique identification information, it can be determined which sensor of which component on which car washing machine.

[0068] Considering the calc...

Embodiment 2

[0101] Please refer to figure 1 , the second embodiment of the present invention is:

[0102] In the predictive operation and maintenance planning method, on the basis of the first embodiment above, step S6 specifically includes the following steps:

[0103] S61. Obtain the work arrangement information of each maintenance personnel, and judge whether there are maintenance personnel whose work arrangement information still has an arrangement margin on the current day, and if so, add the maintenance personnel whose work arrangement information still has an arrangement allowance on the current day to be arranged Personnel assembly, if it does not exist, then execute step S64, the arrangement margin is that the maintenance personnel still have free time to perform maintenance after completing the work arrangement information;

[0104] Among them, for the maintenance personnel who can still perform maintenance on the same day, the maintenance order to be allocated can be dispatche...

Embodiment 3

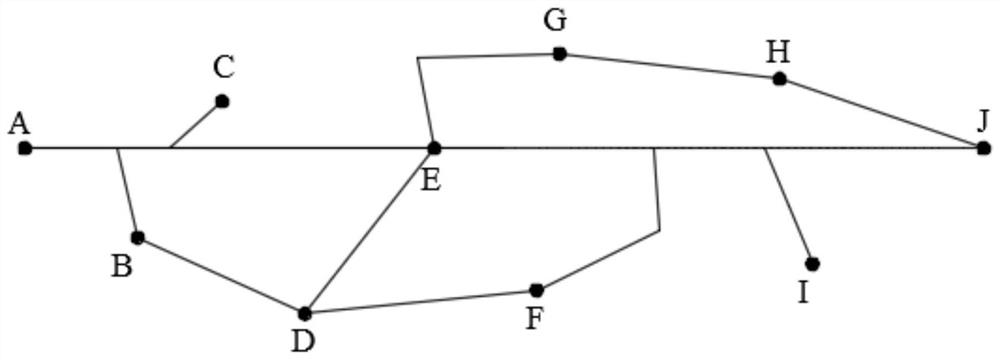

[0130] Please refer to figure 1 and figure 2 , Embodiment three of the present invention is:

[0131] The predictive operation and maintenance planning method, on the basis of the first or second embodiment above, maximizes the processing capacity of maintenance orders by reasonably dispatching orders to maintenance personnel. The third embodiment thus obtained, if the maintenance personnel Start at the same location, that is, if figure 2 The uniform position shown is point A, then figure 2 Points B to J in all correspond to a maintenance order to be processed, and the following steps are also included after step S6:

[0132] S71. Obtain a first undistributed person to be assigned and a first set of maintenance orders to be processed, assign the first order farthest from the unified position in the first set of maintenance orders to be processed to the first person to be assigned, and obtain a second set of pending maintenance orders;

[0133] that is, figure 2 The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com