Rotary compressor, method for manufacturing rotary compressor, and refrigeration cycle device

A technology of rotary compressor and rotary shaft, which is applied in the direction of rotary piston/oscillating piston pump components, rotary piston machinery, pump combinations for elastic fluid rotary piston/oscillating piston, etc., which can solve problems that cannot Get lubricating performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

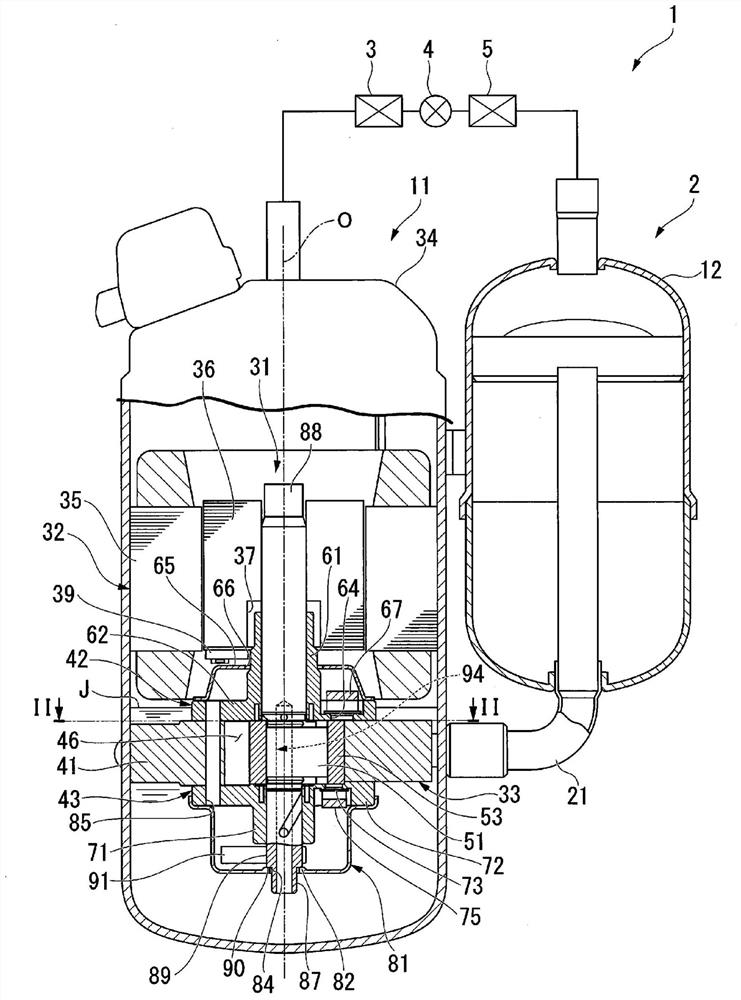

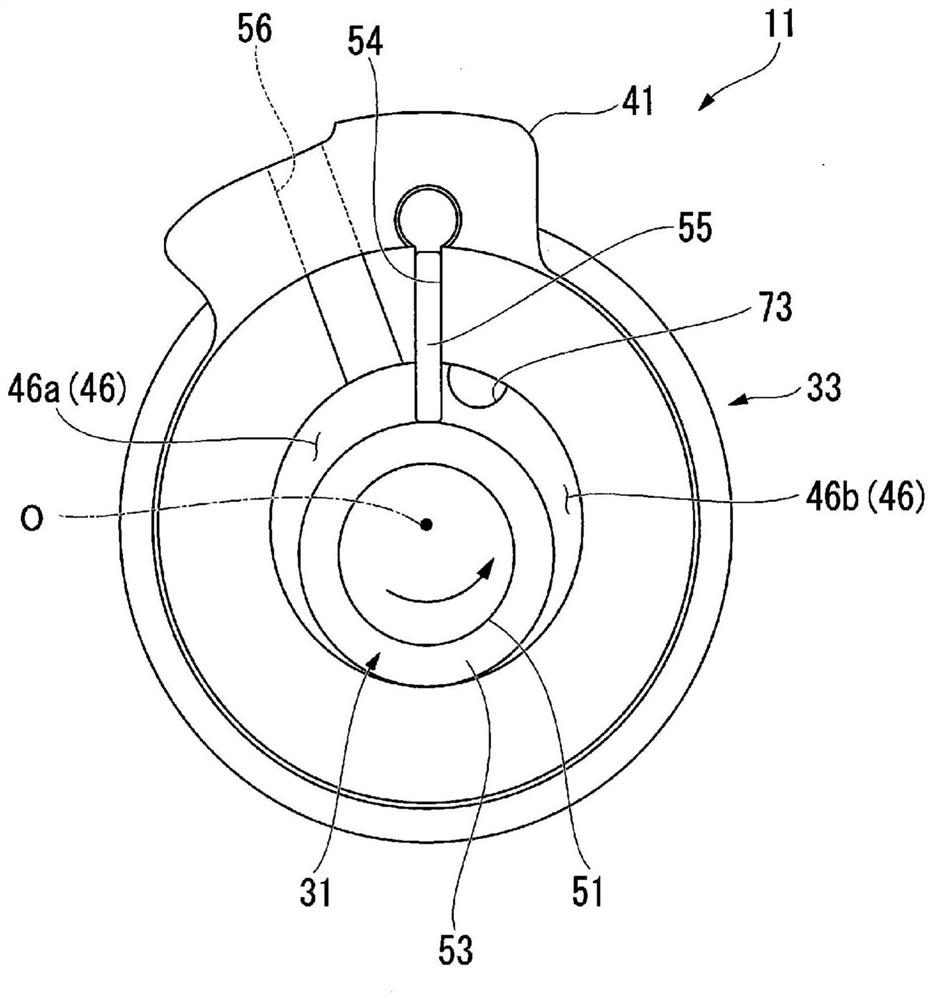

[0019] First, the refrigeration cycle device 1 will be briefly described. figure 1 It is a schematic configuration diagram of the refrigeration cycle apparatus 1 including a cross-sectional view of the rotary compressor 2 in the first embodiment.

[0020] Such as figure 1 As shown, the refrigeration cycle apparatus 1 of the present embodiment includes a rotary compressor 2, a condenser 3 as a radiator connected to the rotary compressor 2, an expansion device 4 connected to the condenser 3, and an expansion device connected to the expansion device. 4 and the evaporator 5 as a heat absorber between the rotary compressor 2.

[0021] The rotary compressor 2 is a so-called rotary compressor. The rotary compressor 2 compresses the low-pressure gas refrigerant taken inside to turn it into a high-temperature and high-pressure gas refrigerant. In addition, the specific structure of the rotary compressor 2 will be mentioned later.

[0022] The condenser 3 radiates heat from the high...

no. 2 Embodiment approach

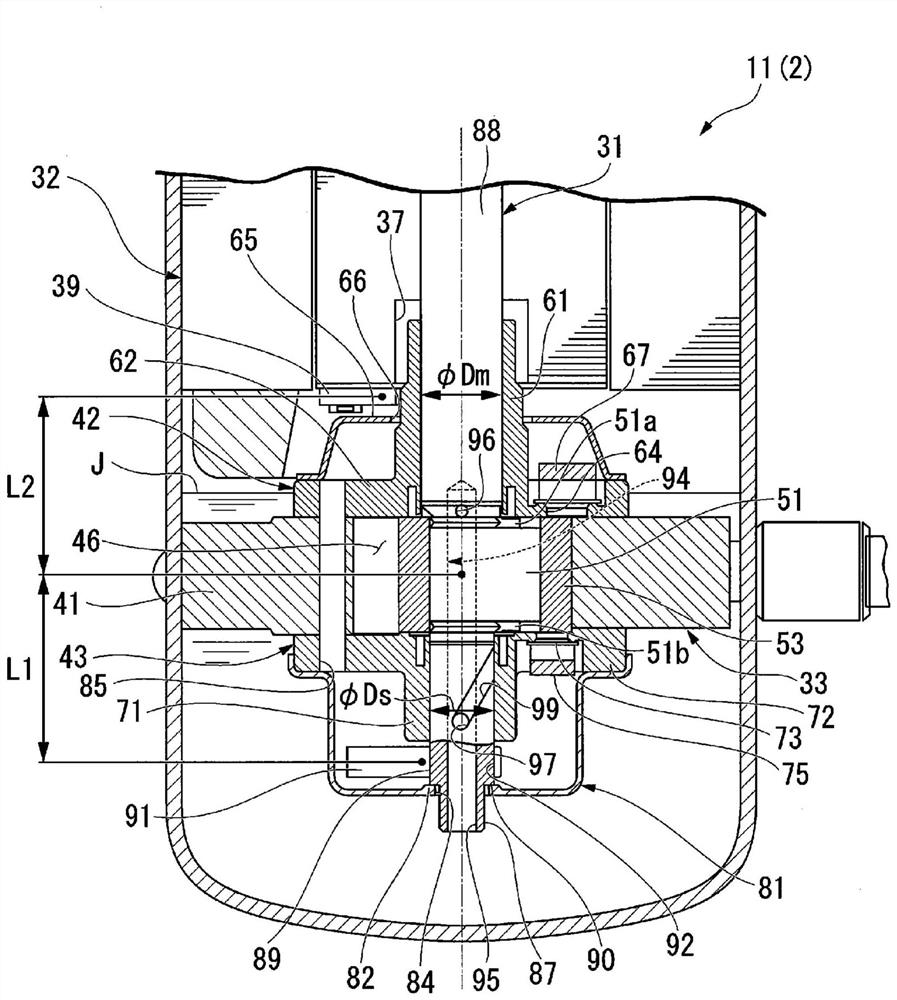

[0087] Figure 4 It is a partial sectional view of the rotary compressor 200 of 2nd Embodiment. In the following description, the same reference numerals are assigned to the same configurations as those in the above-mentioned embodiments, and description thereof will be omitted.

[0088] The difference between the rotary compressor 200 of this embodiment and the above-mentioned first embodiment is that a plurality of (for example, three) cylinders (upper cylinder 201, middle cylinder 202, and lower cylinder 203) are arranged along Axial arrangement.

[0089] exist Figure 4 In the rotary compressor 200 shown, the upper cylinder 201 and the intermediate cylinder 202 are butted in the axial direction with the upper partition 210 interposed therebetween. The middle cylinder 202 and the lower cylinder 203 are butted in the axial direction with the lower partition 211 interposed therebetween. In addition, the structure of each cylinder 201-203 is the same as that of the said em...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap