Double-layer high-pressure jet grouting diaphragm wall inner clamping vertical plastic laying device and construction method thereof

A technology of high-pressure rotary spraying and vertical plastic laying, which is applied in the direction of construction, earth mover/excavator, etc. It can solve the problems of reducing the efficiency of grooves with different widths, so as to improve the efficiency of grooves, improve the effect of grooves, Increase the effect of the width range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

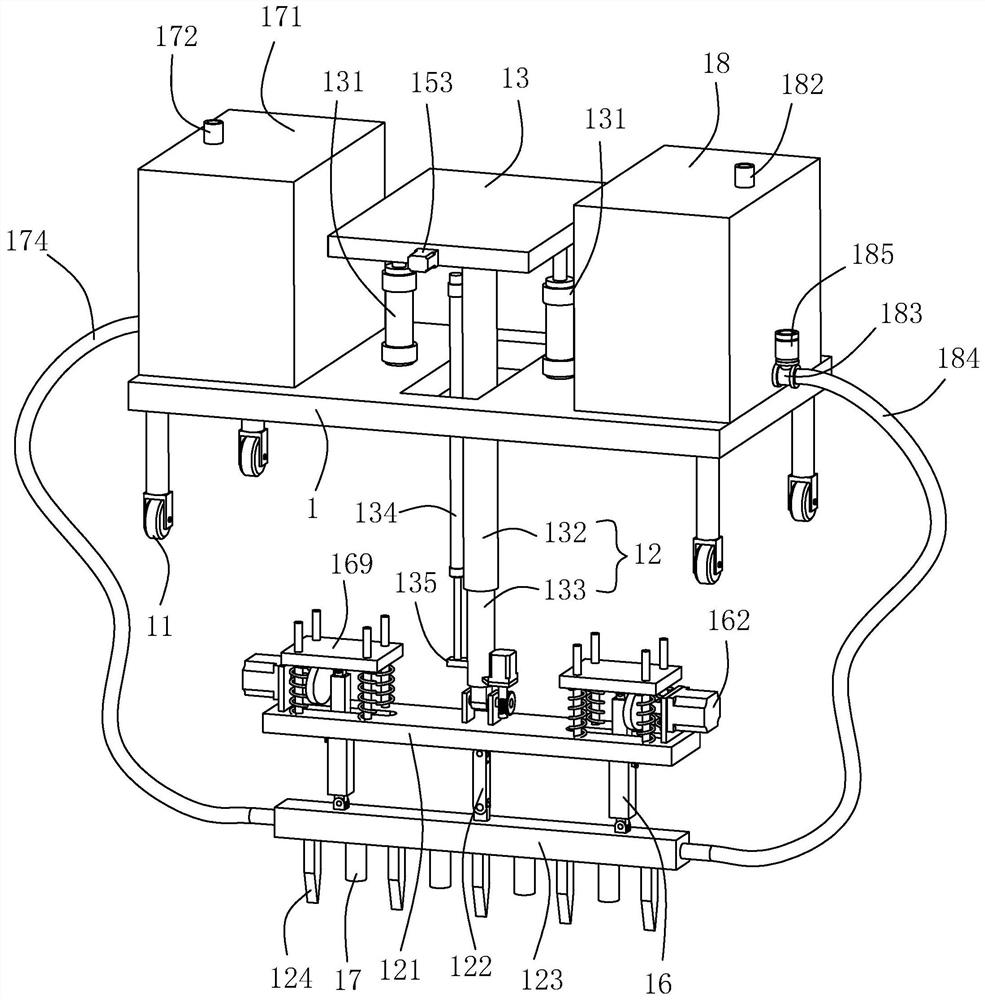

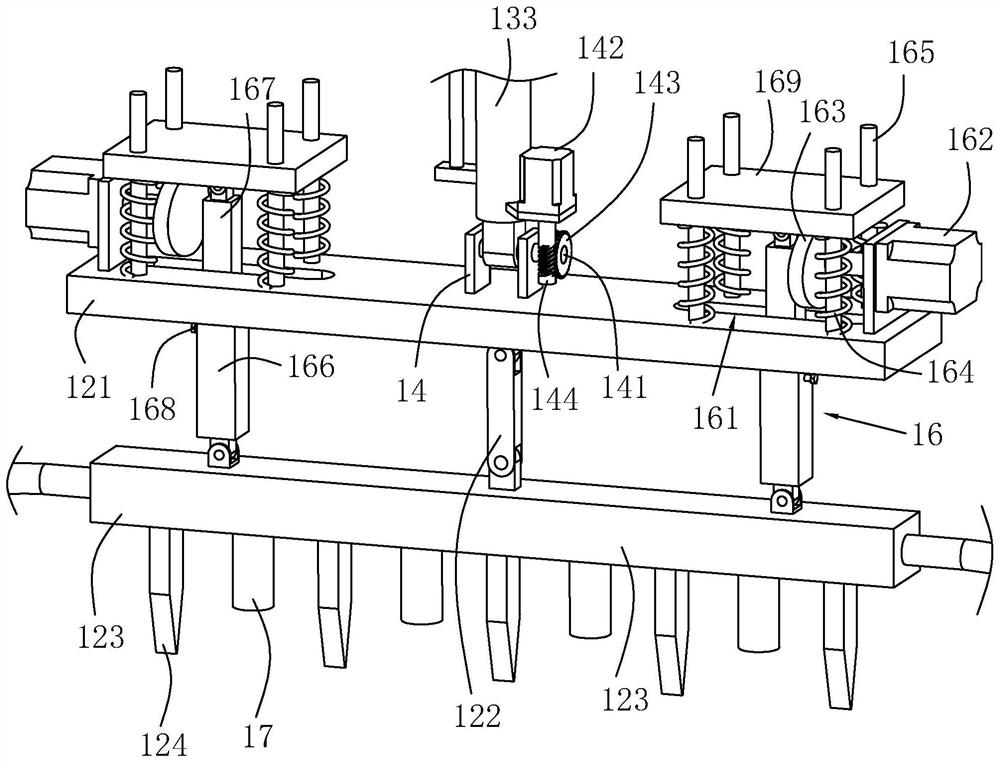

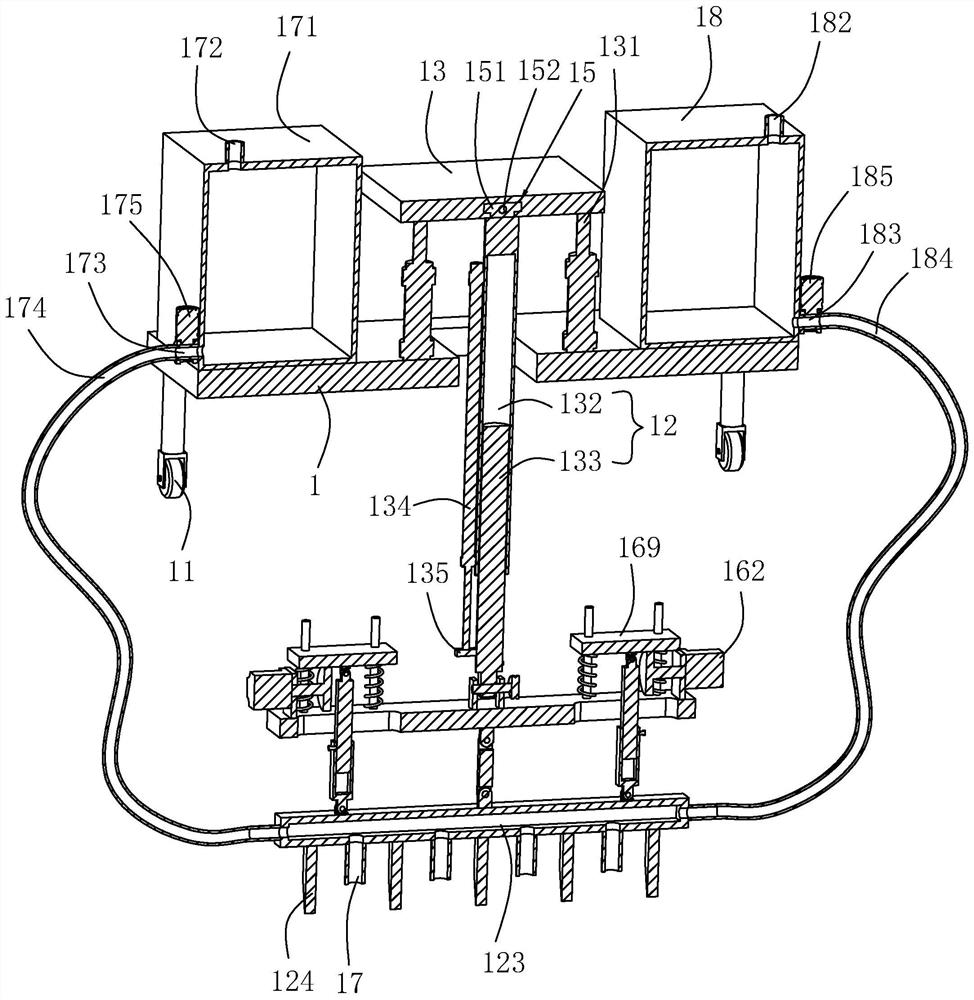

[0040] The following is attached Figure 1-3 The application is described in further detail.

[0041] The embodiment of the present application discloses a vertical plastic laying device for double-layer high-pressure rotary spraying anti-seepage walls. refer to figure 1 , a double-layer high-pressure rotary spray anti-seepage wall clamping vertical plastic laying device, comprising a moving plate 1, rollers 11 are arranged under the moving plate 1 and located at the four corners of the moving plate 1, a rod body 12 is pierced on the moving plate 1, and the rod body 12 The end portion below the moving plate 1 is provided with a mounting rod 121, the mounting rod 121 is hingedly provided with a hinged rod 122 on the surface away from the rod body 12, and the end of the hinged rod 122 away from the mounting rod 121 is hingedly provided with a connecting rod 123, and the connecting rod 123 away from the face of the mounting rod 121 along the length direction of the connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com