Single-opening wall crack intelligent grouting joint filling machine and construction method

A caulking machine and grouting technology, applied in building maintenance, construction, building construction, etc., can solve the problems of high use cost, low repair efficiency, poor aesthetics, etc., and achieve flexible use, improve aesthetics, and use costs. bottom effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

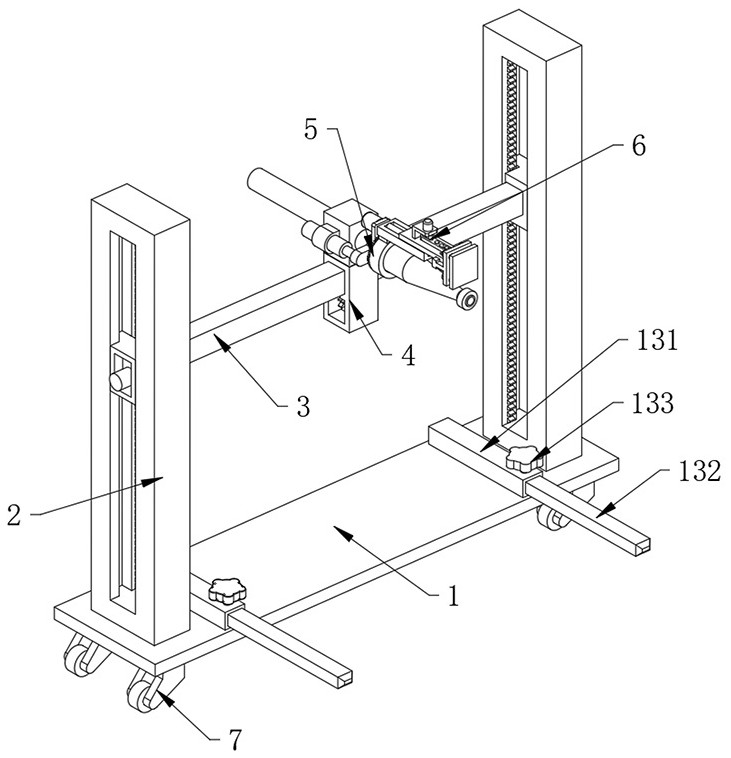

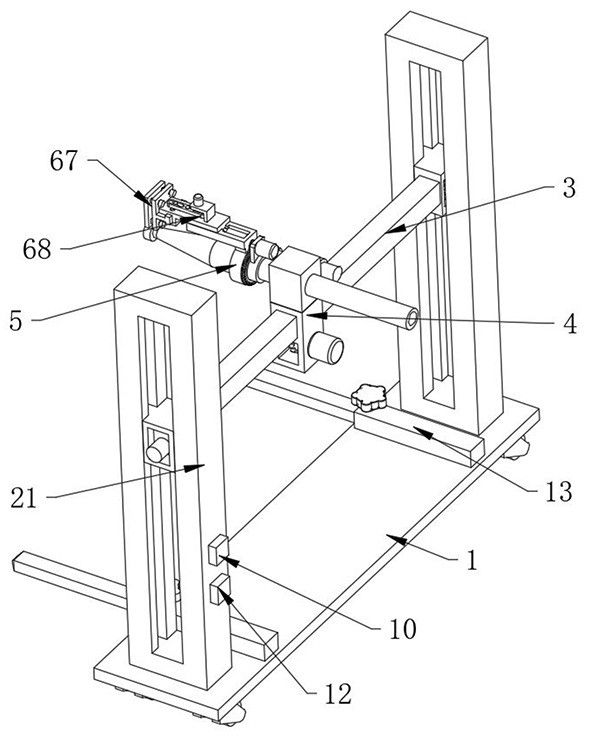

[0051] In the specific implementation process, such as figure 1 and figure 2 As shown, a single-port intelligent grouting and caulking machine for wall cracks includes a bottom plate 1, a lifting mechanism 2 is symmetrically fixed on the upper surface of the bottom plate 1, and a connecting beam 3 is fixed between the two lifting mechanisms 2. The middle part of the connecting beam 3 is slidingly connected with a horizontal moving device 4, the top of the horizontal moving device 4 is fixed with a grouting mechanism 5, the top of the grouting mechanism 5 is fixed with a smoothing mechanism 6, and the lower surface of the bottom plate 1 is symmetrically fixed with Self-locking universal wheel 7;

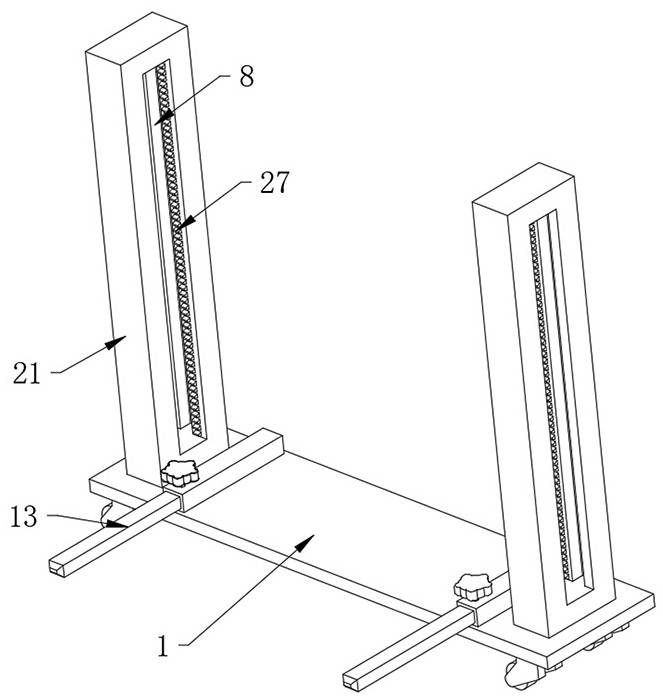

[0052] Please refer to image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the lifting mechanism 2 includes a fixed frame 21, a first slider 22, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com