Damping coupling and sampling needle lifting structure and a manual valve composed of damping coupling

A coupling and damping technology, which is applied in the field of sampling needle lifting structure and manual valve, can solve the problems of high cost and complicated torque control, and achieve the effect of low cost and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

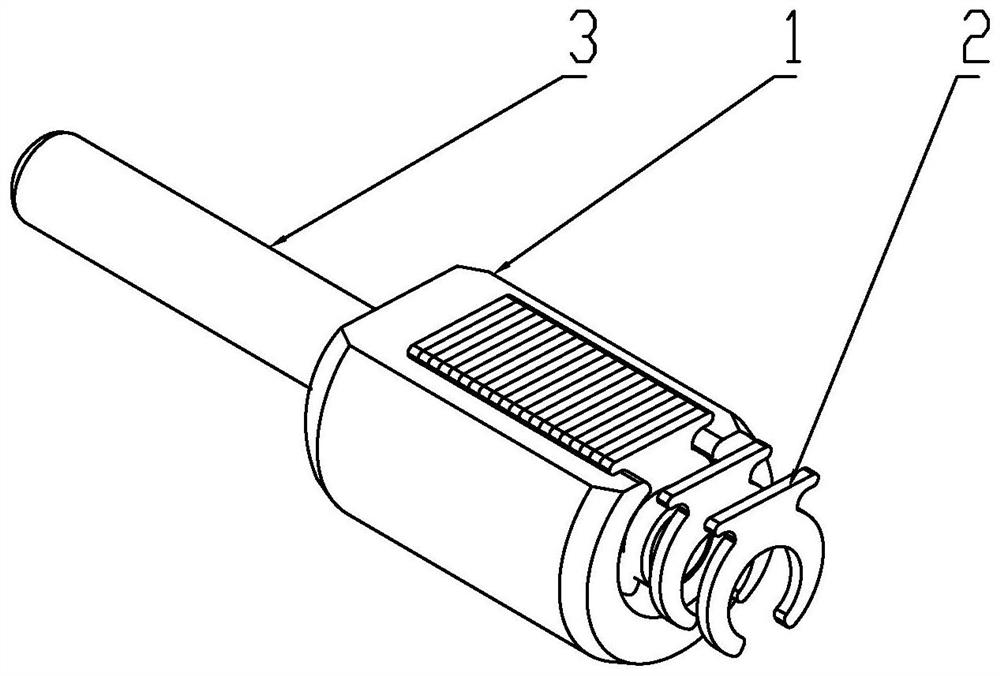

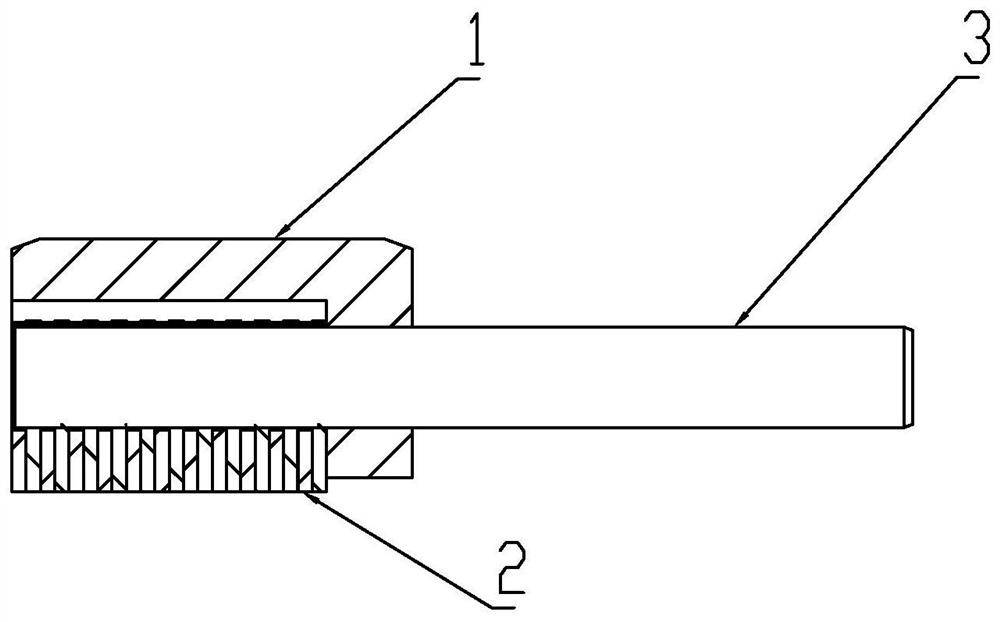

[0027] Such as Figure 1-Figure 3 As shown, the present invention provides a damping coupling, which has a main body 1, a plurality of damping plates 2 and an output shaft 3, wherein:

[0028] An installation space is formed in the main body 1 for fixing the plurality of damping sheets 2;

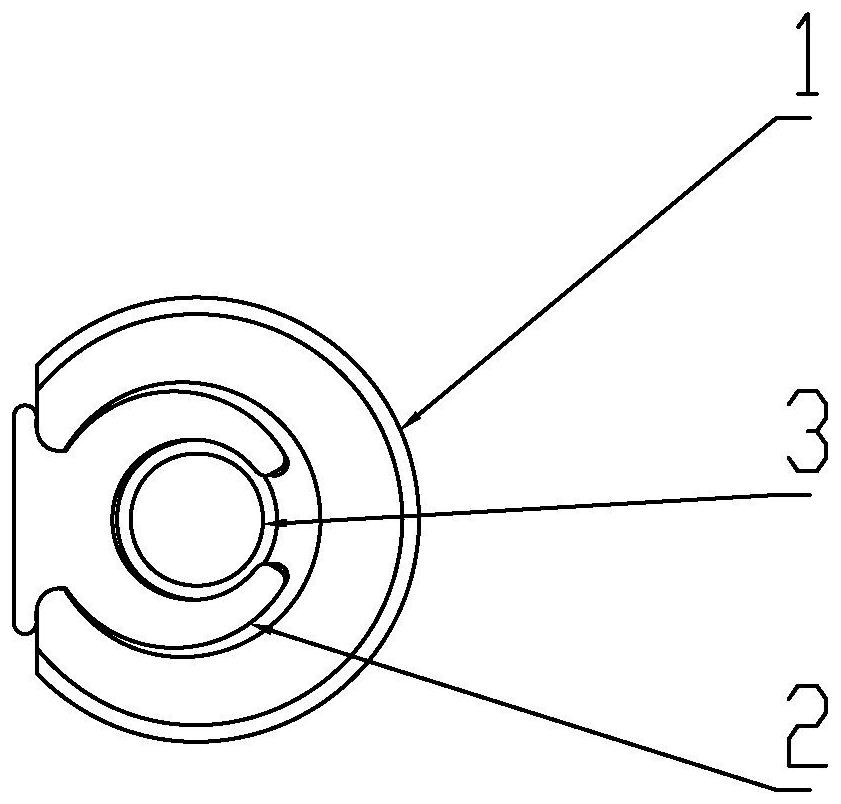

[0029] The damping plate 2 has an outer edge matching the main body 1 and an inner hole matching the output shaft 3, and its preferred structure is as follows Figure 4 As shown, the inner hole is an arc-shaped open hole with a central angle of more than 120 degrees, and the outer edge is provided with two positioning parts (preferably positioning hooks 21) arranged opposite to each other; the plurality of damping sheets 2 are arranged in layers In the installation space of the main body 1, the two positioning hooks 21 of the damping sheet 2 are resisted by the inner wall of the installation space of the main body 1 and cannot rotate in both directions;

[0030] Part of the length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com