Abrasion compensation mechanism for jaw crusher

A jaw crusher and wear compensation technology, applied in the field of wear compensation mechanism, can solve the problems of low service life of the fixed jaw tooth plate, wear, and the fixed jaw tooth plate cannot play a good crushing effect, etc., and achieve the effect of improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

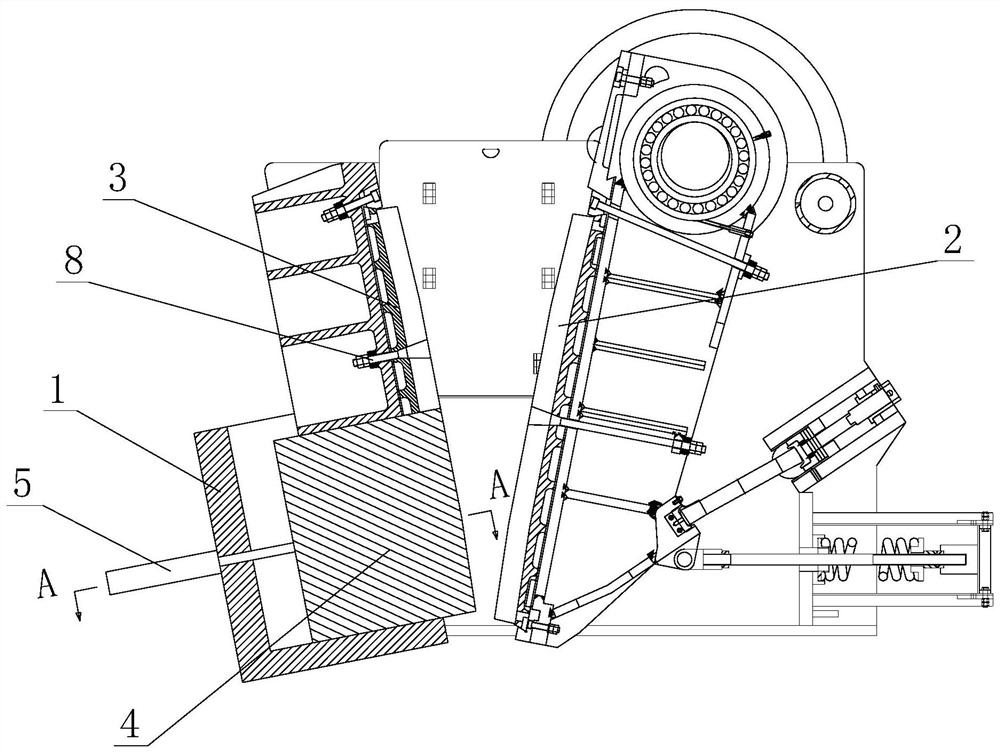

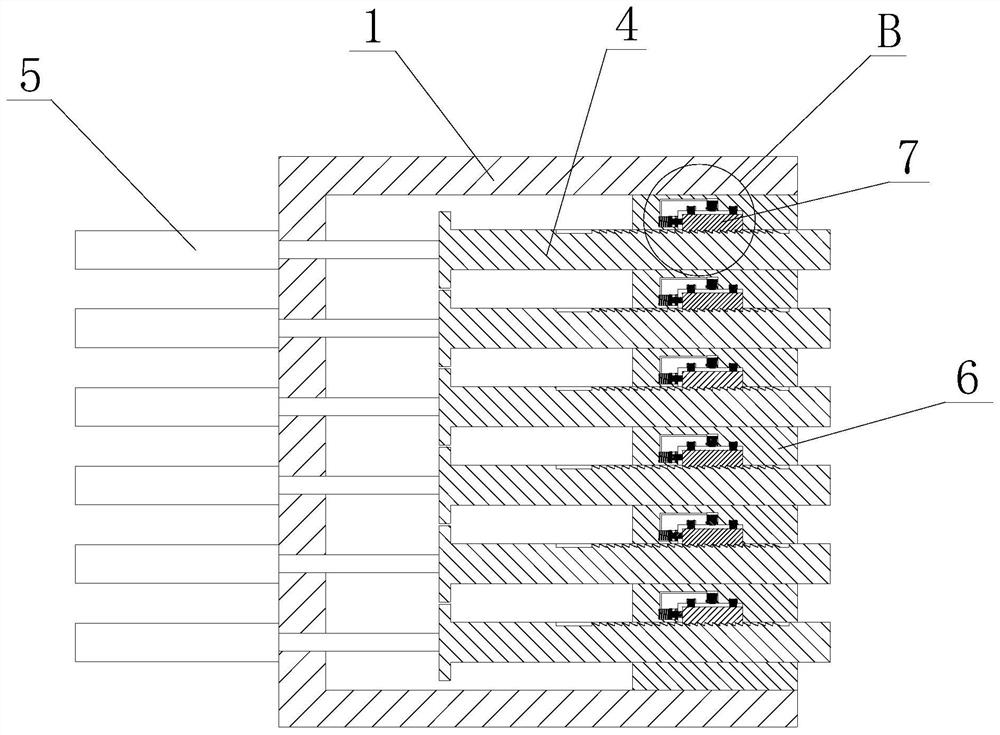

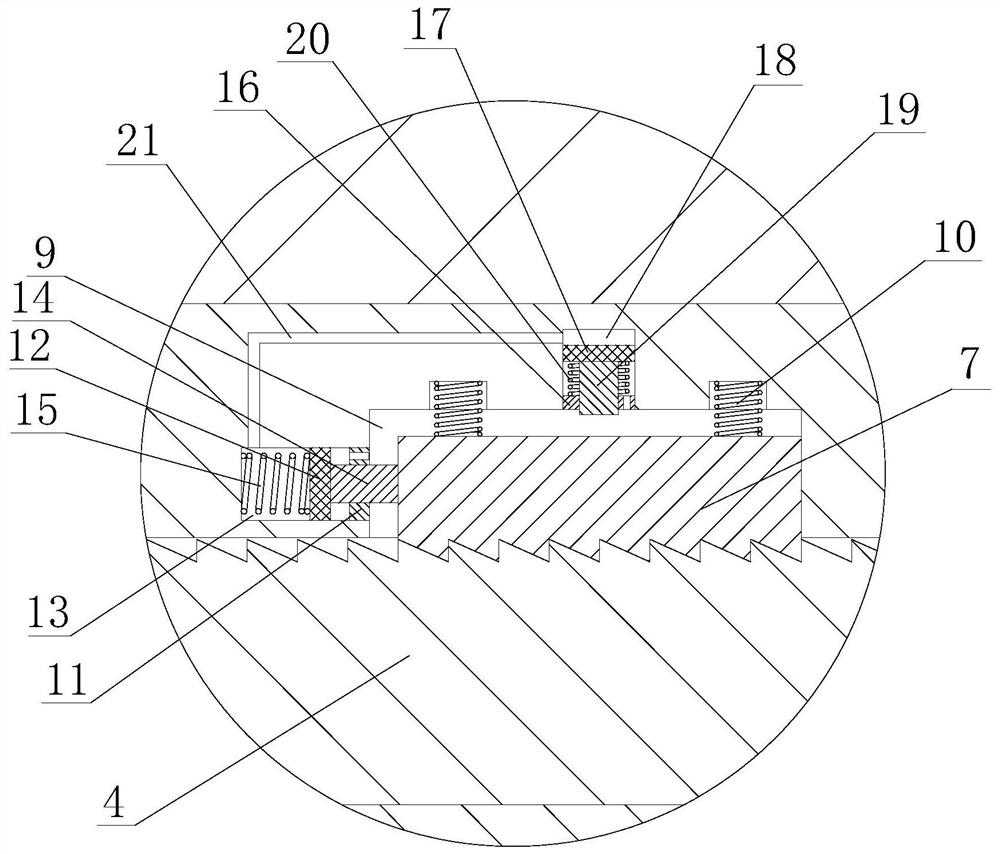

[0020] like Figure 1 to Figure 3 As shown, a wear compensation mechanism for a jaw crusher includes a frame 1, a fixed jaw tooth plate and a movable jaw tooth plate 2 opposite to the fixed jaw tooth plate, the fixed jaw tooth plate and the movable jaw tooth plate 2 in a "V" shape. A crushing cavity is formed between the tooth plate of the fixed jaw and the tooth plate of the movable jaw, and a discharge port is formed between the lower end of the tooth plate of the fixed jaw and the lower end of the tooth plate of the movable jaw. The fixed tooth plate includes an upper fixed tooth plate 3 fixed on the frame 1 and a lower adjustable tooth plate located below the upper fixed tooth plate 3 . The upper fixed tooth plate 3 is a traditional tooth plate structure, and strip-shaped crushing teeth are arranged on it. The upper fixed tooth plate 3 is fixedly arranged on the frame 1 by fixing bolts 8 . The lower adjustable tooth plate includes a tooth block holder 6 fixed on the fra...

Embodiment 2

[0025] The difference between Embodiment 2 and Embodiment 1 is that in Embodiment 2, the pushing device 5 is an electric cylinder, and other structures are the same as those of Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap