Method for repairing automobile rolling mold

A repair method and rolling technology, applied in the direction of metal material coating process and coating, can solve the problems of poor surfacing process accuracy, affecting the life of the roller, and increasing the cost, so as to improve the repair quality, reduce enterprise costs, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

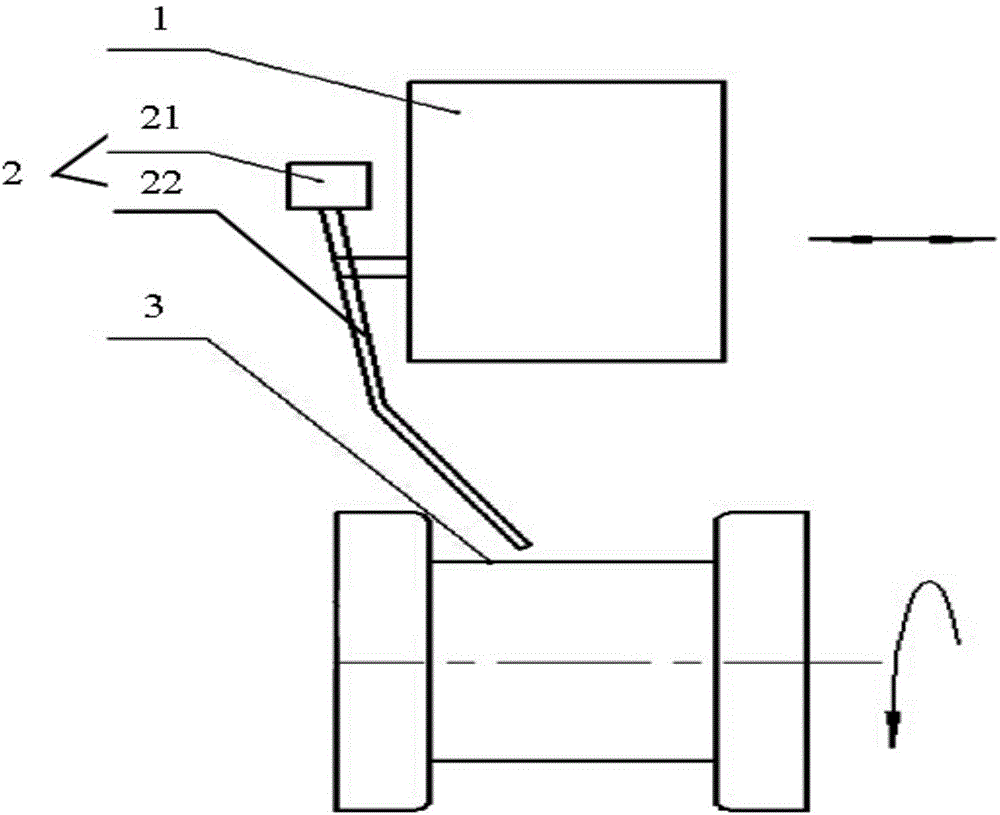

[0032] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

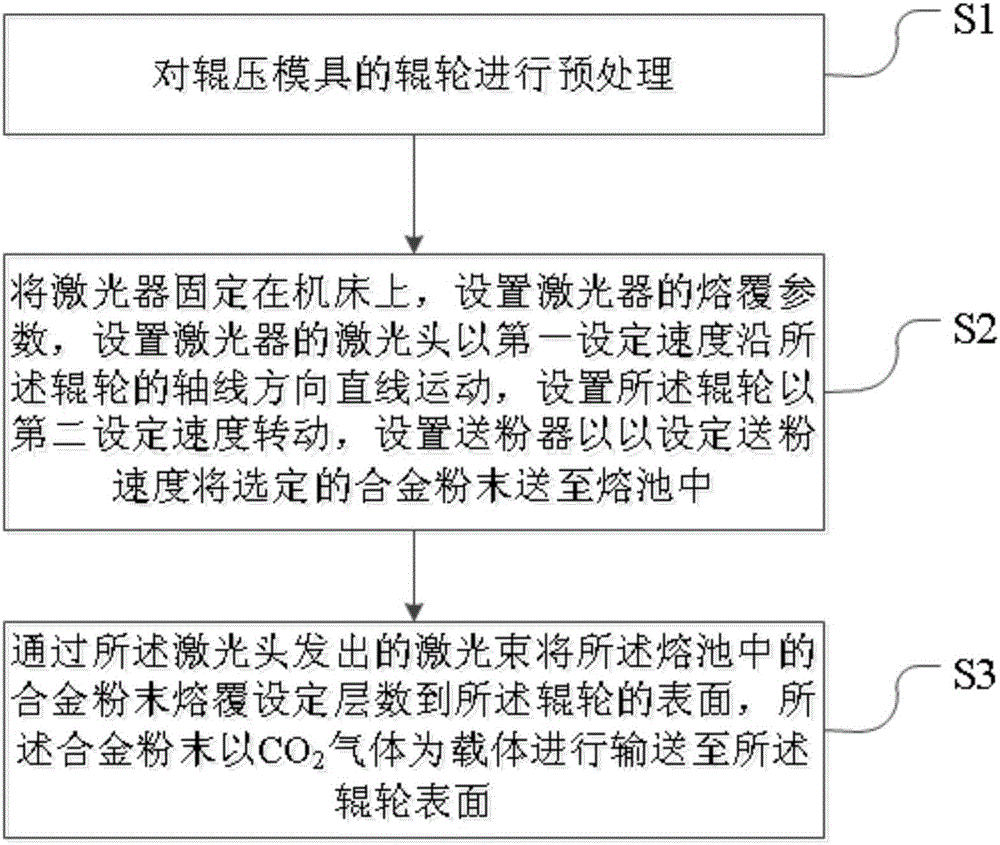

[0033] figure 1 The flow chart of the repair method of the automobile rolling die provided for the embodiment of the present invention, as figure 1 As shown, the repair method of the automobile rolling mold provided by the embodiment of the present invention comprises the following steps:

[0034] Step S1: Perform pretreatment on the rollers of the rolling mold. The pretreatment is mainly to ensure that the rollers can be fully and accurately repaired. The pretreatment can be as follows: according to the wear of the rollers of the roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap