Carbon fiber high-strength shock-resistant hinge

A carbon fiber, high-strength technology, applied in the field of high-strength carbon fiber anti-seismic hinges, can solve the problems of large impact force of the box containing the goods, high requirements for anti-seismic and impact resistance, disintegration of the main product, etc., to achieve light weight, improve anti-shock performance, increase effective Bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

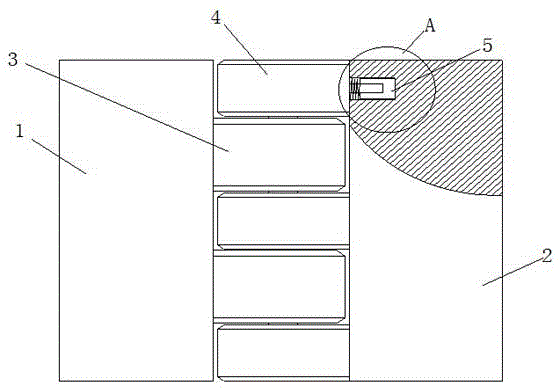

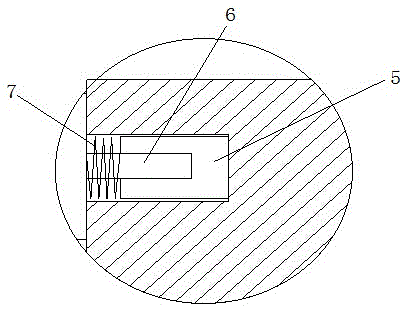

Image

Examples

Embodiment 1

[0016] The invention is a carbon fiber high-strength anti-seismic hinge, which includes a rotating shaft, a main hinge plate and a secondary hinge plate, one end of the main hinge plate is provided with two main hinge joints arranged in parallel, and one end of the secondary hinge plate is provided with three secondary hinge joints. Connecting sleeves are arranged between the main hinge plate and the main hinge connector, and between the auxiliary hinge plate and the auxiliary hinge connector; the main hinge connector and the auxiliary hinge connector are arranged at intervals; the main hinge connector The rear part of the connecting head of the auxiliary hinge and the auxiliary hinge is provided with a connecting column, which is inserted into the connecting sleeve, and a spring is arranged between the connecting head of the main hinge, the connecting head of the auxiliary hinge and the connecting sleeve; the rotating shaft passes through the main hinge The connecting head and...

Embodiment 2

[0021] The difference between the technical solution of this embodiment and Embodiment 1 is that: the carbon fiber content of the main hinge joint, the auxiliary hinge joint, the main hinge plate and the auxiliary hinge plate is 70%.

Embodiment 3

[0023] The difference between the technical solution of this embodiment and Embodiments 1 and 2 is that the carbon fiber content of the main hinge joint, the auxiliary hinge joint, the main hinge plate and the auxiliary hinge plate is 65%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap