A kind of food waste waste liquid pretreatment device

A pretreatment device and technology for kitchen waste, which are applied in grain treatment, solid waste removal, presses, etc., can solve the problems of high moisture content of solid slag and increased cost of incineration of kitchen waste, and achieve the effect of low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

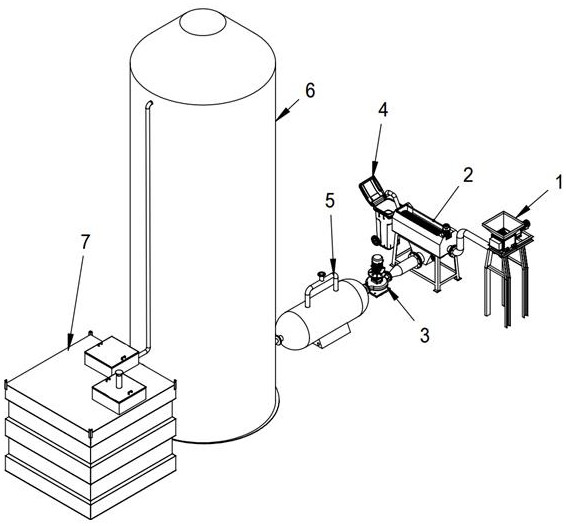

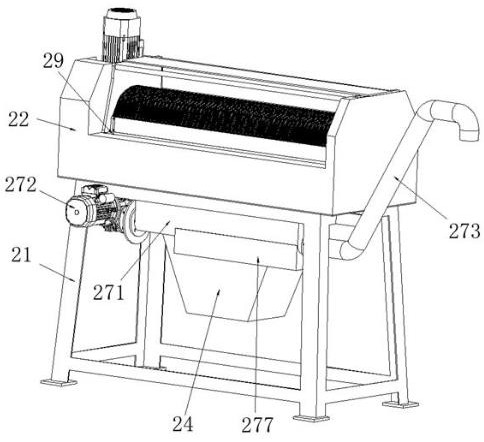

[0045] see figure 1 As shown, a kitchen waste waste liquid pretreatment device includes a crushing mechanism 1, a solid-liquid separation mechanism 2, a vertical pipeline pump 3, a garbage bin 4, a three-phase separator 5, a UASB anaerobic tank 6 and an underground type The processing mechanism 7; the crushing mechanism 1 is connected through the solid-liquid separation mechanism 2 through the pipeline one, the water outlet 25 of the solid-liquid separation mechanism 2 is connected with one end of the vertical pipeline pump 3 through the pipeline two, and the other end of the vertical pipeline pump 3 is passed through Pipeline three is connected to one end of three-phase separator 5, the other end of three-phase separator 5 is connected to the bottom side of UASB anaerobic tank 6 through pipeline four, and the top side of UASB anaerobic tank 6 is connected to the ground through pipeline five The top of one side of the buried processing mechanism 7 is through-connected;

[004...

Embodiment 2

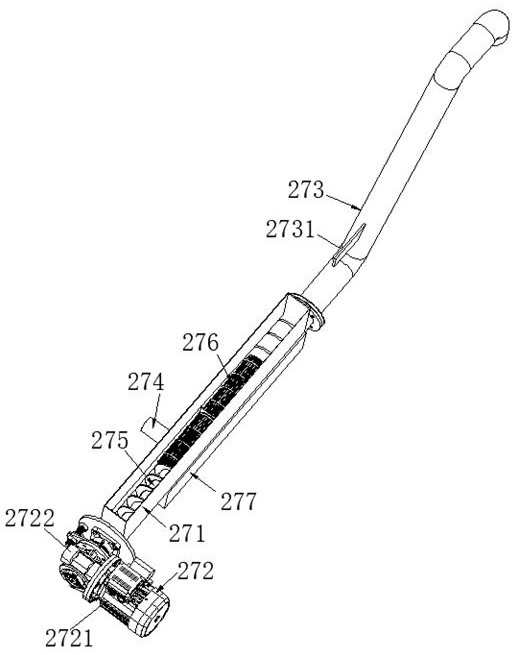

[0062] see Figure 14 As shown, the solid slag climbing conduit 273 includes a first conduit 2731 and two second conduits 2732; one end of the two second conduits 2732 is respectively through-connected with the two ends of the first conduit 2731 through an arc-shaped connecting pipe 2733; The angle between the axis of the conduit 2731 and the two second conduits 2732 is 120 degrees; the first conduit 2731 and the two second conduits 2732 both include an upper tube body 2734 and a lower tube body 2735; the upper tube body 2734 and the lower tube body 2735 constitute A hollow cylindrical first conduit 2731 or a second conduit 2732; both sides of the upper tube body 2734 and the lower tube body 2735 are uniformly formed with a rectangular plate 2736, between the upper tube body 2734 and the rectangular plate 2736 on the lower tube body 2735 It is fixed by the bolt and nut fixture 2737; by setting the solid slag climbing conduit 273 into the structure of the upper pipe body 2734 a...

Embodiment 3

[0064] see Figure 15 As shown, the dustbin 4 is provided with a monitoring terminal, which includes a load cell, a positioning sensor, an analysis unit and a memory; the load cell is used to regularly collect the weight of the solid slag inside the dustbin 4 and send it to the analysis unit The positioning sensor is used to collect the real-time positioning of the garbage bin 4 and sends it to the analysis unit; the memory is connected to the analysis unit, and the memory stores the personnel information of the garbage cleaning personnel, wherein the personnel information includes name, age, mobile phone number and entry time; The analysis unit receives the solid slag weight from the load cell and analyzes it. The specific analysis process is as follows:

[0065]Compare the weight of the solid slag with the set weight threshold, and when the weight of the solid slag is equal to the set weight threshold, generate a cleaning instruction; send a location acquisition instruction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com