A kind of nb, b microalloyed gear steel and its preparation method, heat treatment method, carburizing treatment method and carburized gear steel

A micro-alloying and carburizing technology, applied in the field of gear steel, can solve the problem of inability to adapt to materials with high contact fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

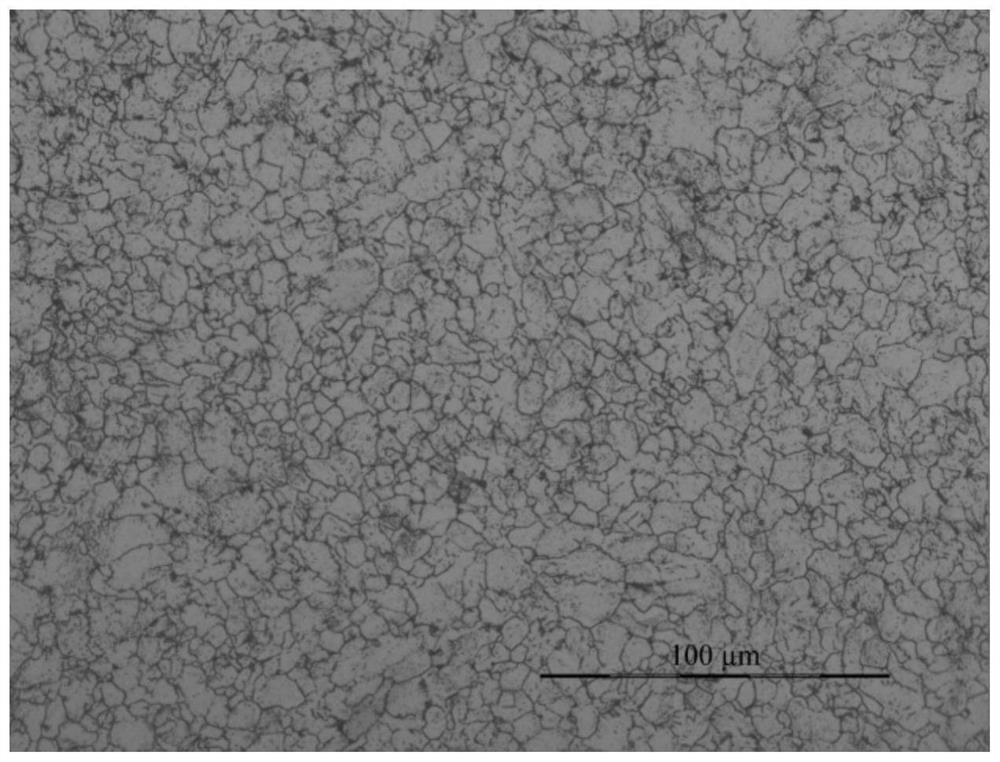

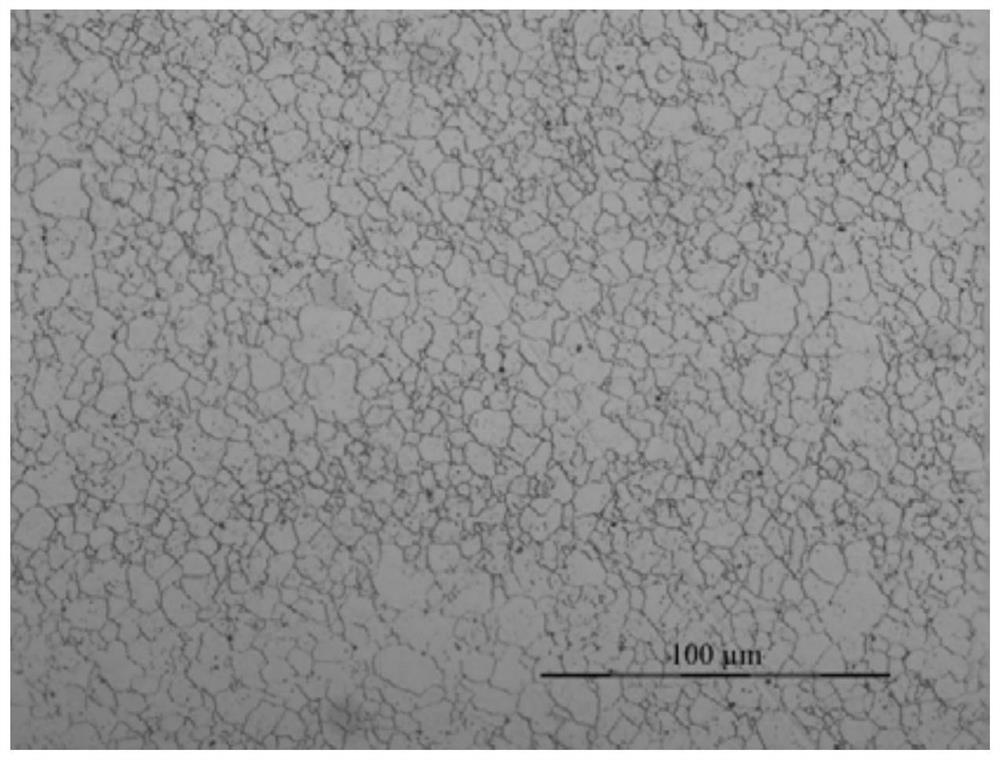

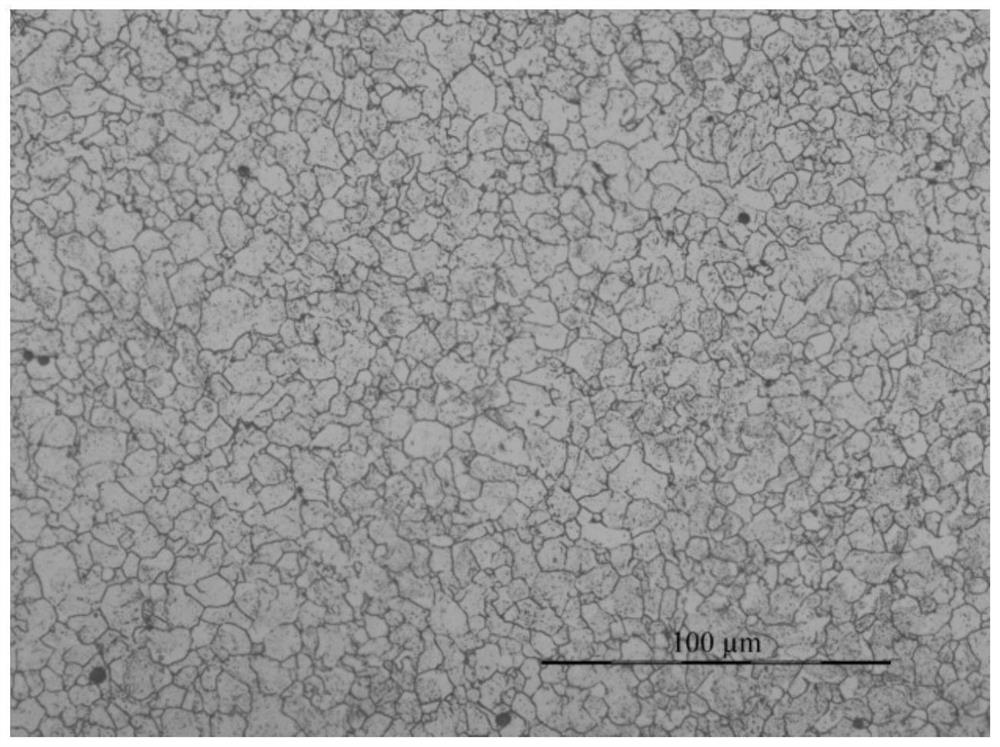

Image

Examples

Embodiment Construction

[0072] A kind of Nb, B micro-alloyed gear steel, comprising the following chemical composition in weight percentage: C: 0.15-0.19%, Si: 0.15-0.30%, Mn: 0.60-0.90%, Cr: 1.60-1.80%, Mo: 0.20 ~0.35%, Nb: 0.025~0.040%, Ni: 1.50~1.70%, Al: 0.020~0.040%, P: ≤0.010%, S: ≤0.010%, B: 0.0005~0.0020%; T.O: ≤10ppm, [ H]: ≤1.0ppm, [N]: 80-120ppm, Al / [N]: 2.5~5.0, the rest are Fe and unavoidable impurity elements, among them, Km=C+Mn / 6+(Cr+Mo+ V) / 5+(Ni+Cu) / 15+10Nb+100[1+1.5(0.9-C)]×B, and Km: 0.97-1.37.

[0073] It adopts the process of electric arc furnace smelting-LF refining-RH vacuum treatment-continuous casting-hot rolling-slow cooling, as follows:

[0074] The continuous casting slab is heated and kept at 1230-1280°C for ≥5 hours before round steel rolling. The rolling start temperature is 1120-1180°C and the final rolling temperature is 930-980°C. After rolling, it is cooled by a cooling bed to ≤650°C and slowly cooled , the slow cooling time is 48 hours, and the skin is ground and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com