High-speed micro-coaxial connector assembly and male connector

A connector assembly, ultra-fine coaxial technology, which is applied in the direction of protective grounding/shielding device of connecting parts, parts of connecting device, connection, etc. Instability and other problems, to achieve the effect of improving transmission stability and anti-interference ability, improving shielding and grounding ability, and saving internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Further detailed description will be made below in conjunction with the accompanying drawings and preferred embodiments.

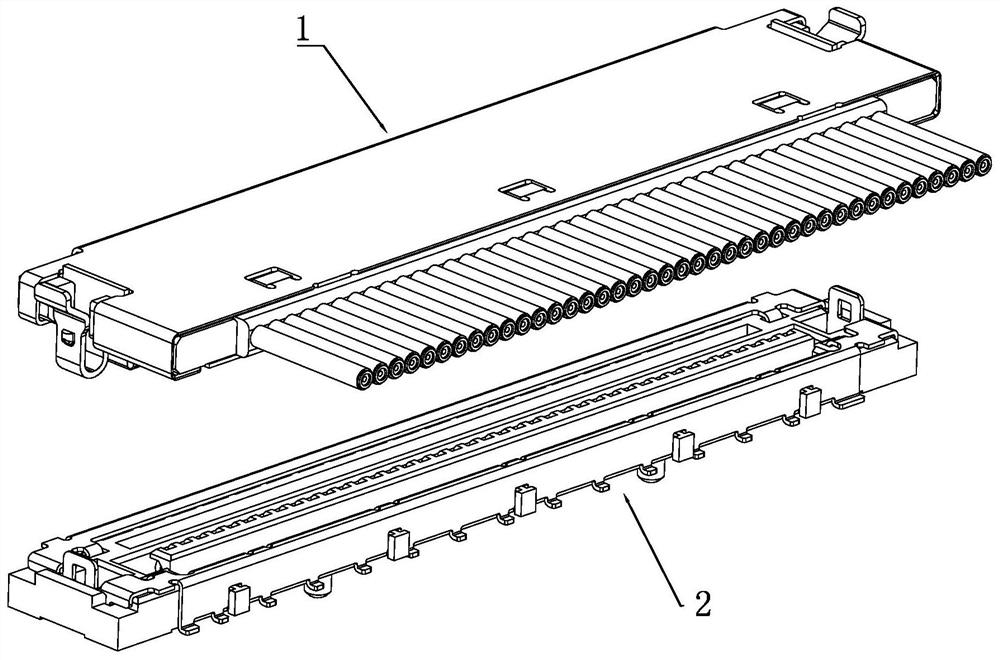

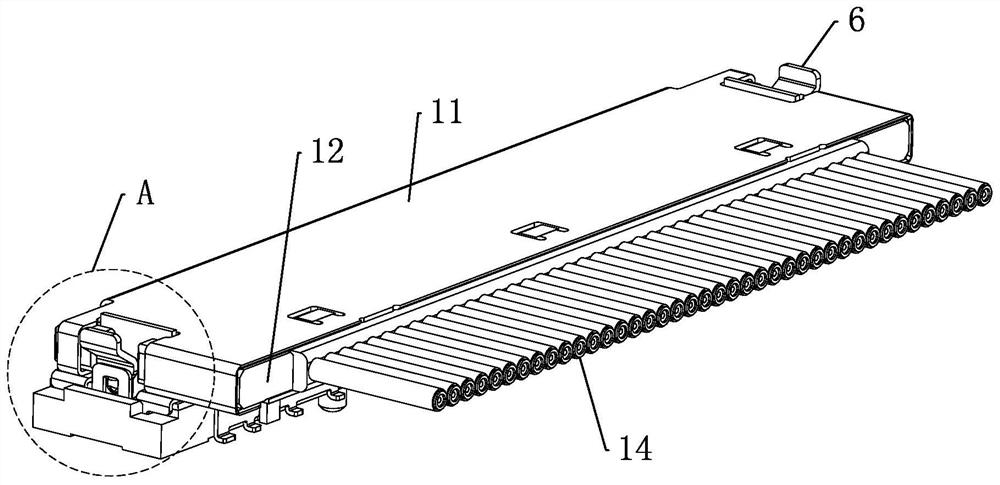

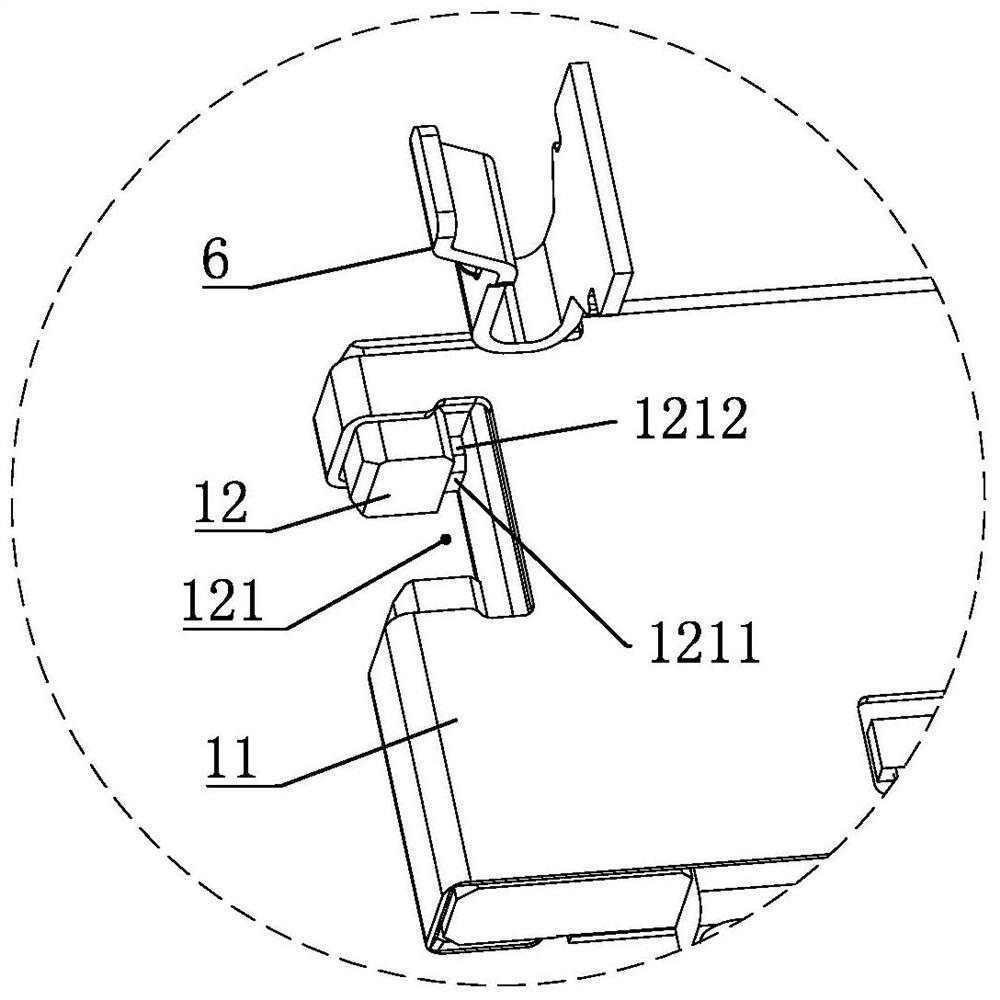

[0043] Examples of high-speed micro-coaxial connector assemblies, such as Figure 1 to Figure 19 , including a mating male connector 1 and a female connector 2, the male connector 1 includes a male shielding shell 11, a male insulator 12 disposed in the male shielding shell 11, arranged in a row on The male terminal 13 in the male insulator 12 and the coaxial cable 14 connected to the male terminal 13 in one-to-one correspondence; the diameter of the coaxial cable is 0.30mm, but the present invention is not limited to this, the coaxial cable The wire diameter of the cable can be adaptively adjusted according to actual needs. The female end connector 2 includes a female end insulator 21, a female end shielding shell 22, and a female end terminal 23 arranged in a row in the female end insulator. The female end shielding shell 22 is installed on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com