Cloth cutting device for garment processing

A cutting device and fabric technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of high labor intensity, large human error, and low cutting efficiency, and achieve high adjustment flexibility and improve use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

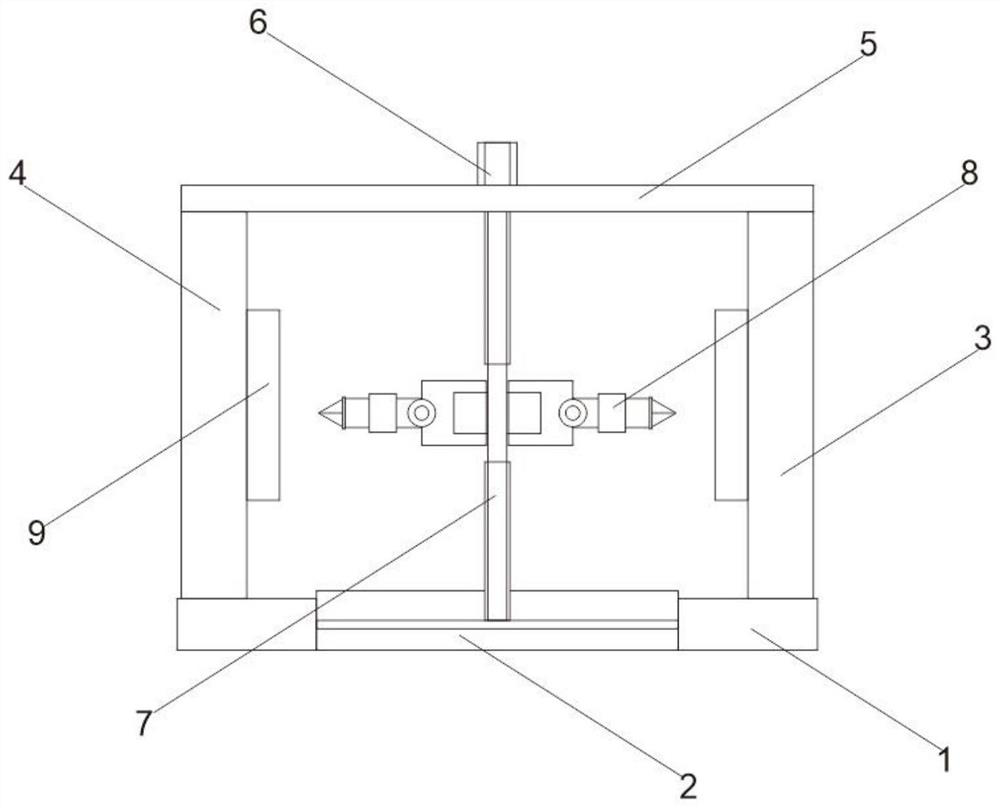

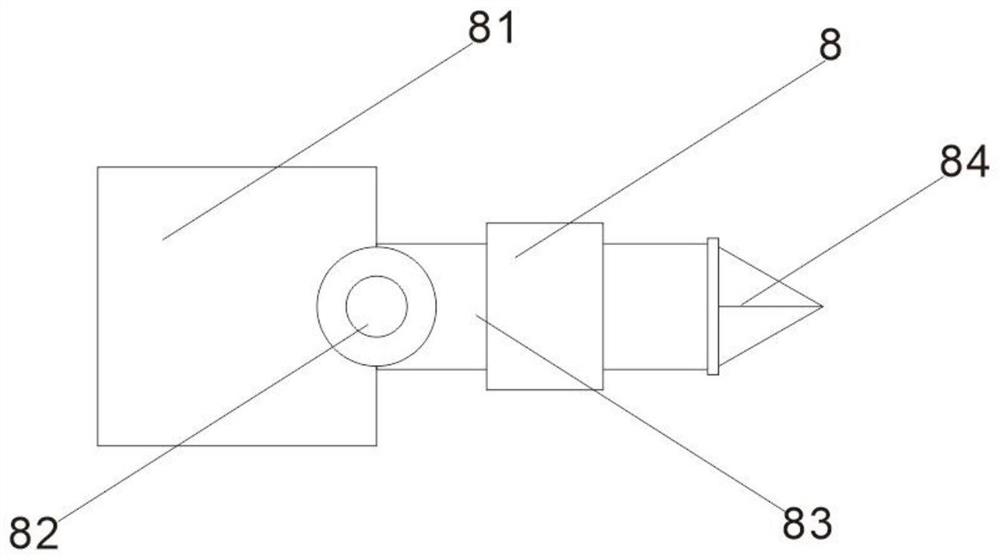

[0031] Firstly, according to the clamping angle of the clothing by the clamping frame 9, the sliding block 81 is used to slide and adjust the height of the cutting mechanism 8 on the connecting rod 7, so as to align the distance and orientation between the clothing and the cutting mechanism 8, and facilitate clothing cutting

specific Embodiment 2

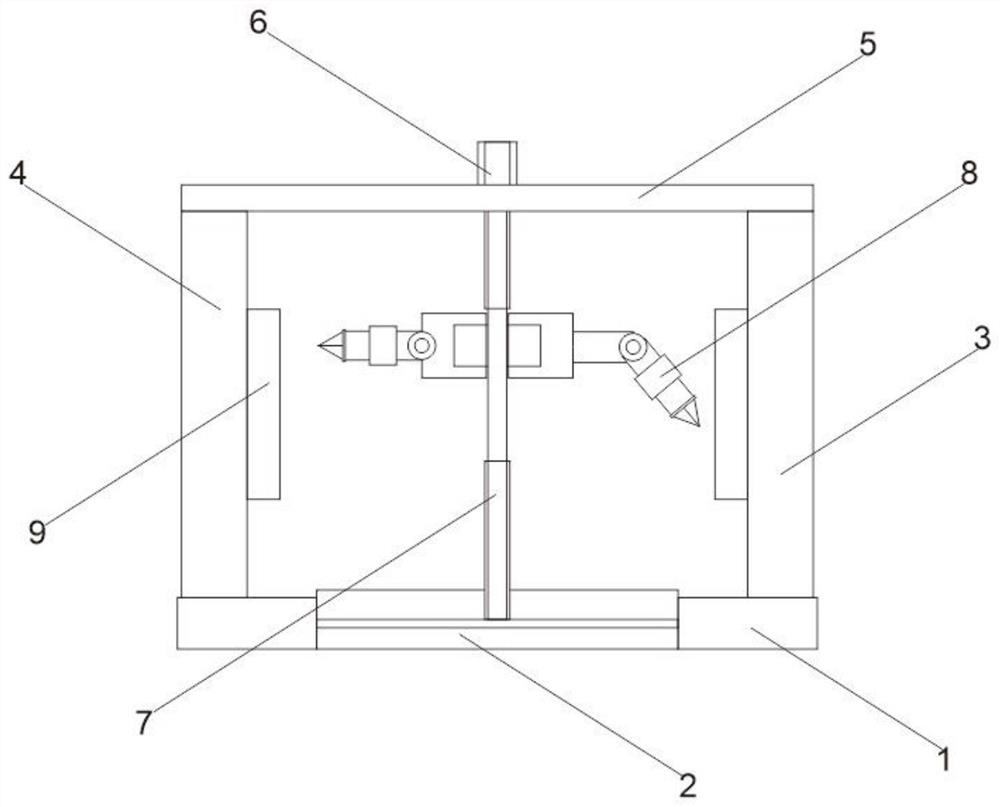

[0033] First, according to the clamping angle of the clamping frame 9 to the garment, use the sliding block 81 to slide and adjust the height of the cutting mechanism 8 on the connecting rod 7, and then use the rotating shaft 82 to adjust the angle of the cutting mechanism 8, thereby aligning the garment and the cutting mechanism 8 The distance, angle and orientation are convenient for multi-angle cutting of clothing.

[0034] The invention has high adjustment flexibility, can carry out the cutting operation of clothes in all directions, and can also carry out two groups of cutting operations at the same time, thereby improving the use efficiency.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap