Industrial automation flexible production line center control low-code platform system, method and device, processor and computer readable storage medium thereof

An industrial automation and processor technology, applied in natural language data processing, computing, comprehensive factory control, etc., can solve the problems of high cost, high technical threshold for modification and maintenance, reduce development costs, reduce customized development, and improve adjustment flexibility. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content of the present invention more clearly, further description will be given below with reference to specific embodiments.

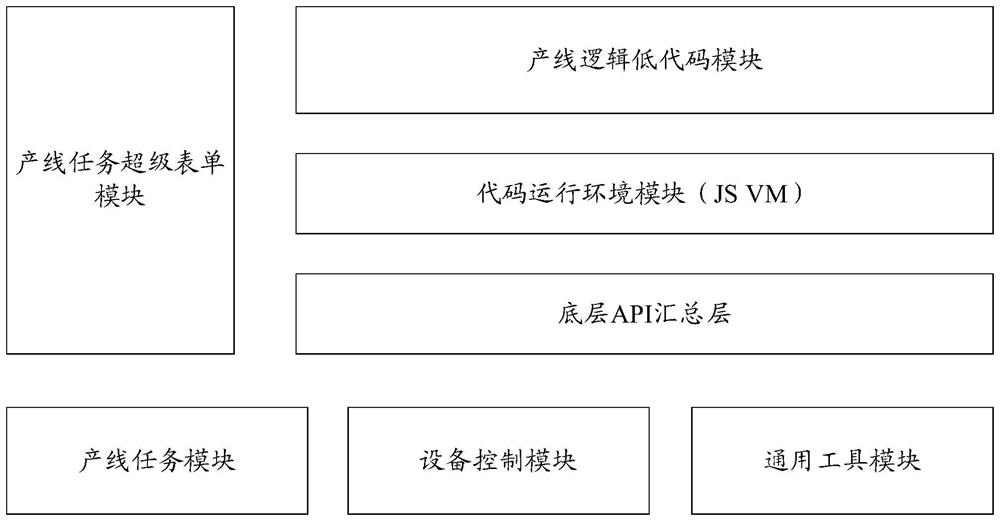

[0034] The central control low-code platform system of the industrial automation flexible production line of the present invention includes:

[0035] The production line task super form module is used to design the production line task super form unit data according to the data types of various parameters, and create the production line task template;

[0036] The production line logic low-code module is connected to the production line task super form module, and is used to write js code according to the production line task;

[0037] The production line task module is connected with the production line task super form module, and is used to provide the basic data type of the production line task modeling, model the production line task, manage the template data, and edit the production line task;

[0038] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap