Adjusting mechanism capable of improving flexibility of welding gun

An adjustment mechanism and flexibility technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that cannot meet the welding accuracy requirements of precision devices, affect the processing quality of precision devices, and cannot guarantee welding accuracy, etc. , to achieve high welding precision, meet the welding precision requirements, and extend the rotation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order for those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and the following embodiments.

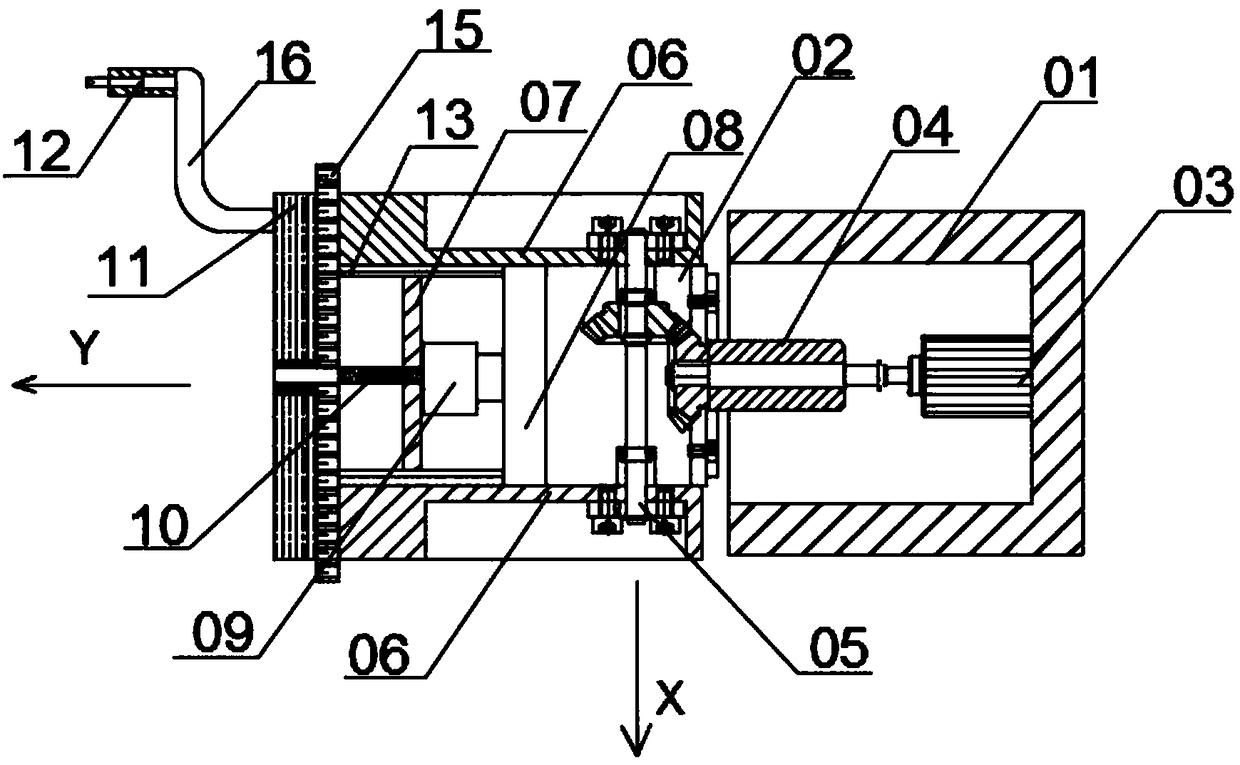

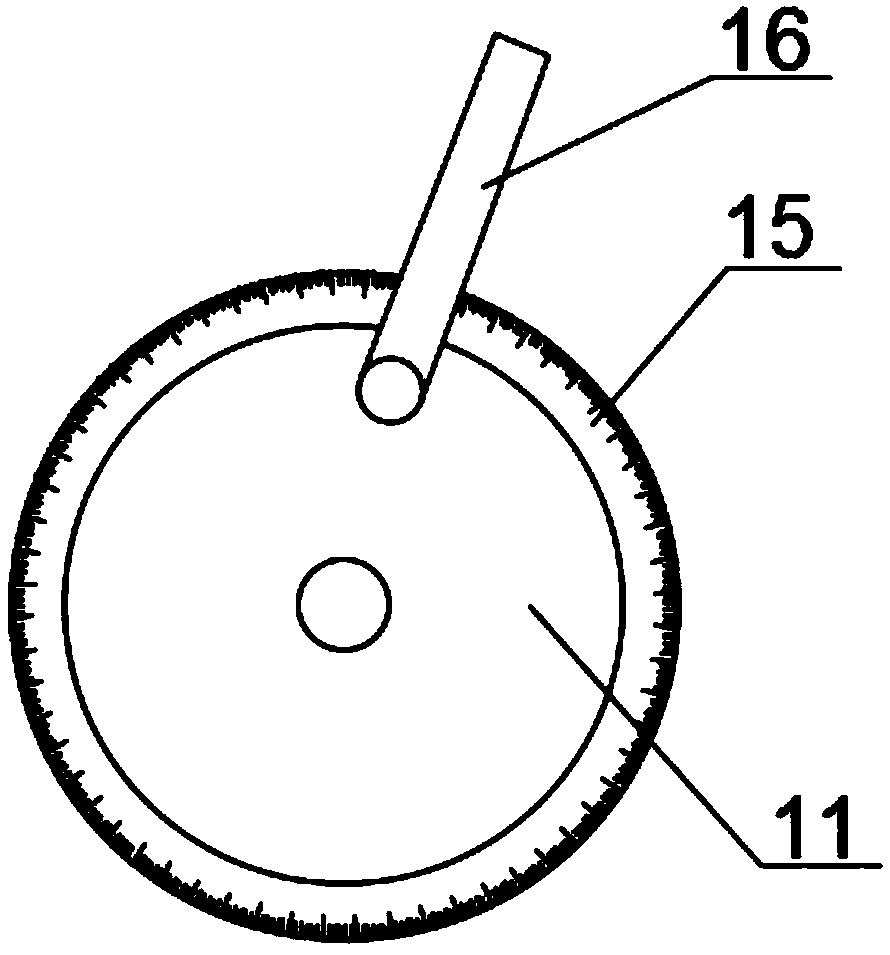

[0022] Please refer to figure 1 As shown, this embodiment provides an adjustment mechanism that can improve the flexibility of the welding torch, including a welding torch 12 and an installation housing for installing the welding torch 12. The installation housing includes a fixed housing 01 and a rotating housing 02. The installation housing is equipped with There is an X-axis rotating assembly that drives the welding torch 12 to perform 180° reciprocating motion along the X axis, and a Y-axis rotating assembly that drives the welding torch 12 to perform 360° rotation along the Y axis. Repeated welding, the welding torch 12 has a high degree of adjustment flexibility; and the welding torch 12 is provided with a laser tracking system and a spectral ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap