Intelligent repairing device for geological profile measurement

A technology of intelligent repair and geological section, which is applied in the direction of safety devices, sampling devices, fillings, etc., can solve the problems of recoil damage of glue liquid, only exposed corners cannot carry out effective sampling, and the space requirement for accommodating warping devices is relatively deep. , to achieve the effect of reducing the air pressure reaction force and avoiding the glue recoil damage to the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

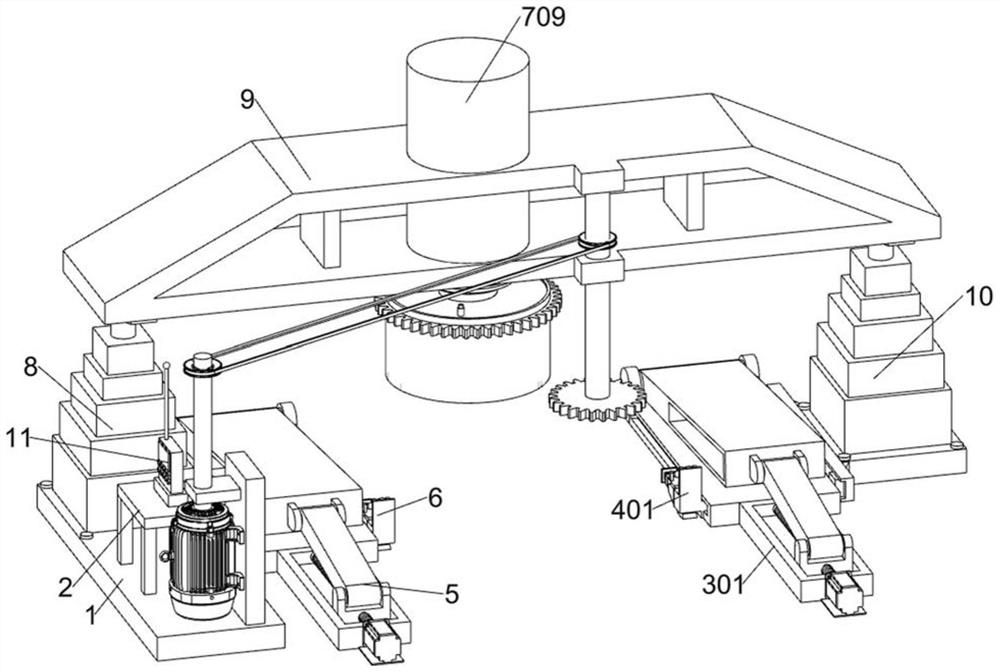

[0039] An intelligent restoration device for geological profile measurement, such as figure 1As shown, it includes an installation base plate 1, an installation platform 2, a first lifting system, a first auxiliary support system, a second lifting system 5, a second auxiliary support system 6, a sampling repair system, and a first electric lifting platform. 8. The installation bracket 9, the second electric lifting platform 10 and the remote sensing controller 11; the middle part of the upper surface of the installation base plate 1 is welded with the installation platform 2; the rear part of the upper surface of the installation base plate 1 is bolted to the first electric lifting platform 8; the first The top bolt of the electric lifting platform 8 is connected with the mounting bracket 9; the bolt on the right part of the lower surface of the mounting bracket 9 is connected with the second electric lifting platform 10; the left bottom of the second electric lifting platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com