A terminal stamping machine

A technology for punching machines and terminals, applied in the field of terminal punching machines, can solve the problems of labor consumption and low processing efficiency, and achieve the effects of saving production costs, improving production efficiency, and realizing positioning and automatic deviation correction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and To facilitate its practice, but not as a limitation of the invention.

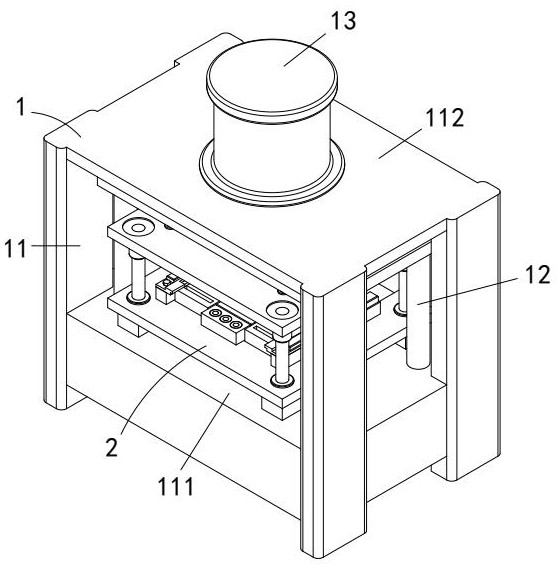

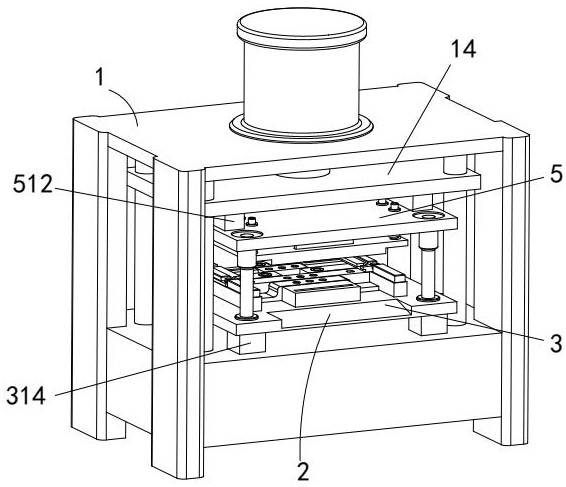

[0031] Such as figure 1 with figure 2 As shown, a terminal stamping machine includes a stamping execution device 1 for performing stamping and a terminal stamping die 2 assembled on the stamping execution device 1; the terminal stamping die 2 consists of a lower die mechanism 3 and an upper die mechanism 5 that cooperate constitute.

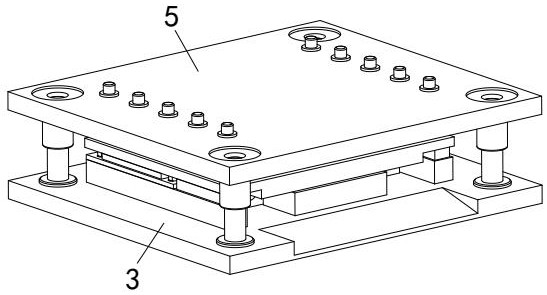

[0032] Such as image 3 , Figure 4 , Figure 5 with Figure 7As shown, the lower die mechanism 3 includes a lower die base plate 31, four No. 1 guide posts 311 are fixedly installed on the upper end surface of the lower di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com