Halogen-free lead-free antioxidant solder paste and preparation method thereof

一种氧化锡膏、锡膏的技术,应用在制造工具、焊接设备、金属加工设备等方向,能够解决电气绝缘性能下降、抗坍塌性能不强、增加生产成本等问题,达到改进润湿性能、优化合金强度和抗氧化性能、抑制气孔的产生的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

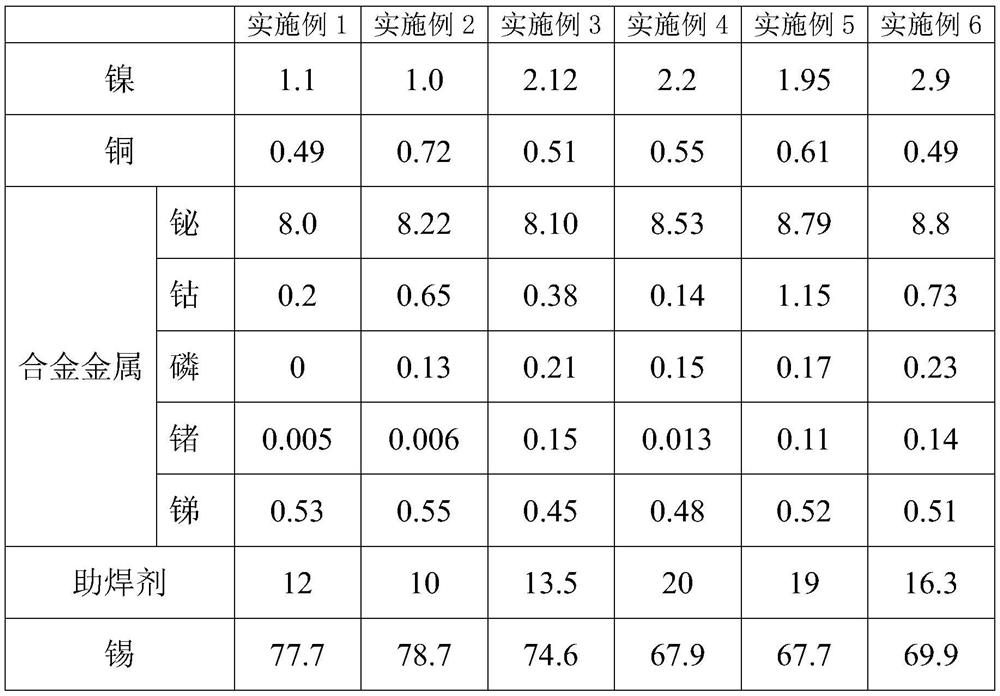

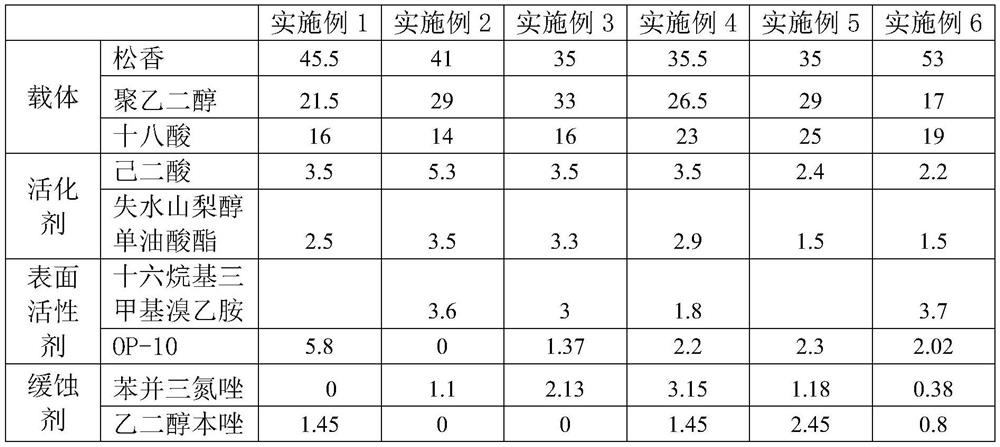

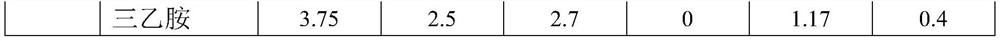

Embodiment 1~6

[0039] A preparation method of halogen-free lead-free anti-oxidation solder paste:

[0040] A. Mix the activator and the carrier evenly in proportion, and heat to 120-135°C to completely dissolve to make the primary mixture a;

[0041] B. Mix the corrosion inhibitor and surfactant evenly, and heat to 95-105°C to completely dissolve to obtain the primary mixture b;

[0042] C. Mix and stir the primary mixture a and primary mixture b, completely dissolve and cool to make flux, and place it in an environment with a temperature of 2°C to 10°C for use;

[0043] D. After the prepared flux is left to stand for 24 hours, add Sn~Ni solder powder and alloy element powder except Cu according to the weight ratio, mix and stir and evaporate in the emulsifier at 125~135°C for 3.2~3.7H, After cooling down to 45°C, add copper powder and stir evenly, and refrigerate at 0-4°C to obtain the finished solder paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com