Construction device and construction method of expressway roadbed

A construction device and expressway technology, which is applied in infrastructure engineering, roads, roads, etc., can solve the problems of easy hardening of roadbed soil and rock, a large amount of manpower and material resources, and low work efficiency, so as to achieve the effect of strengthening and leveling the roadbed and reducing dust , Improve the effect of dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

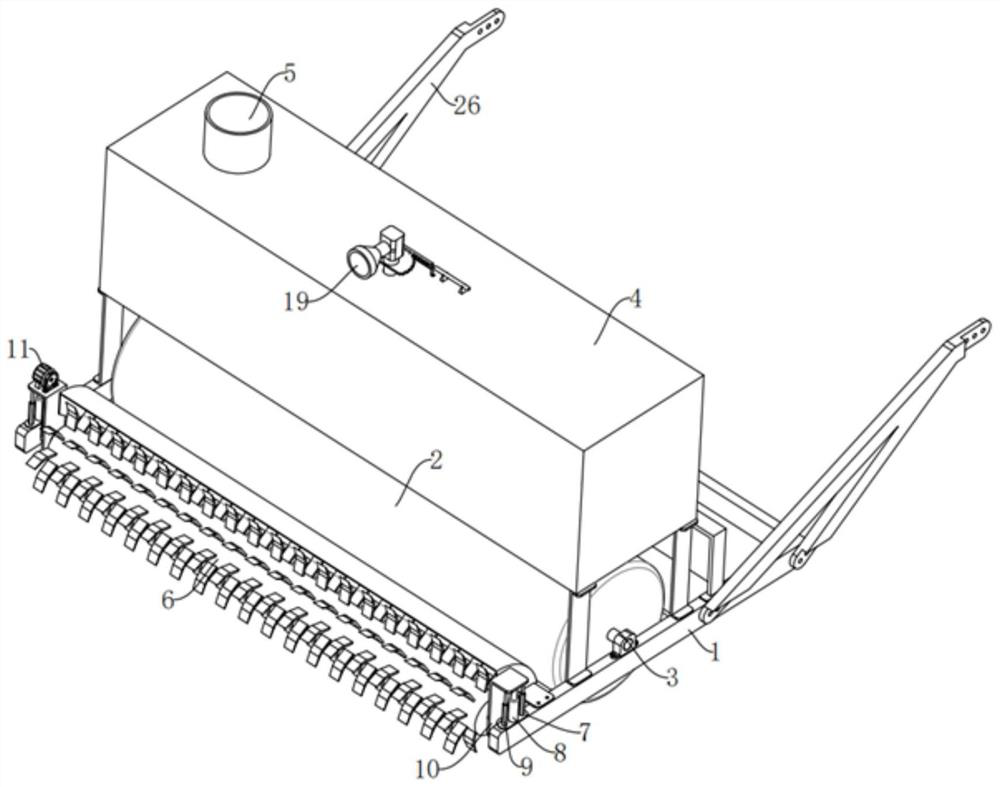

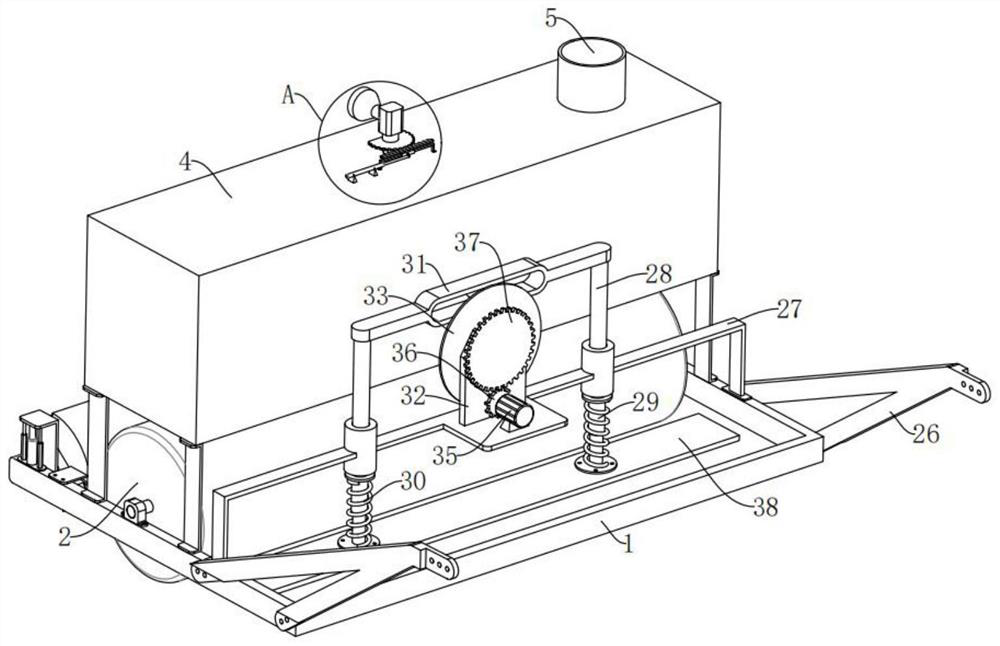

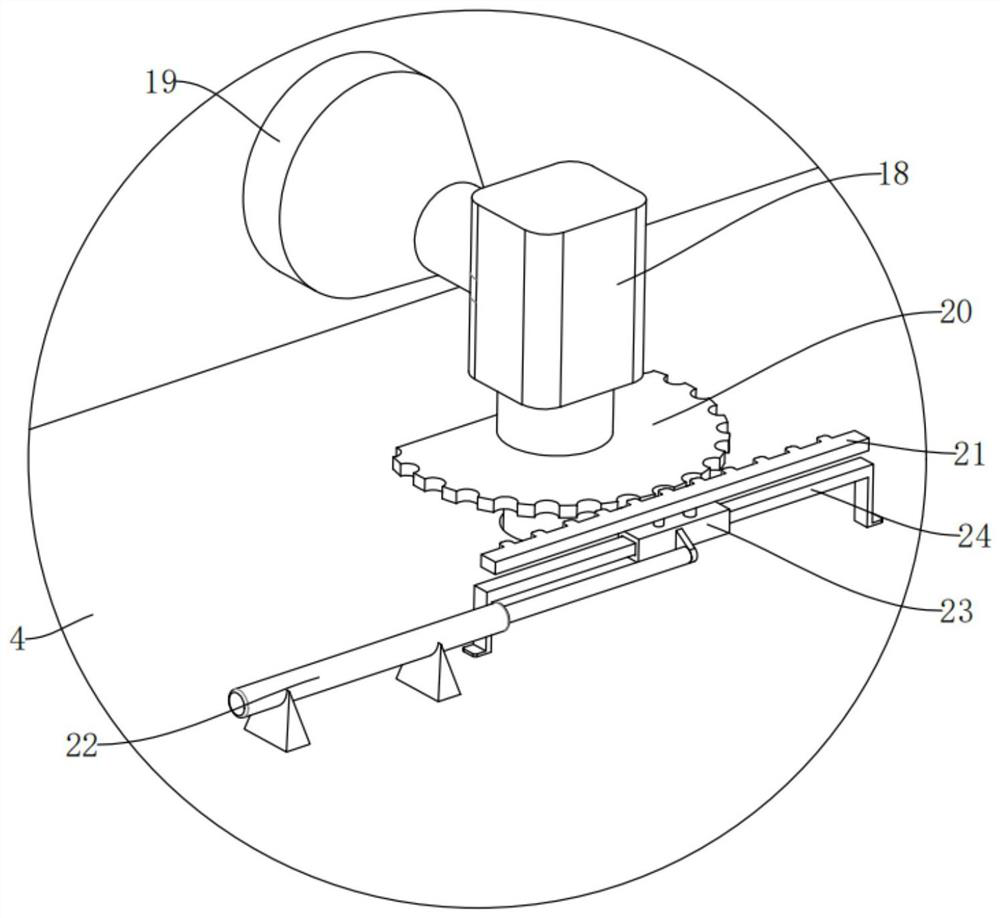

[0036] A construction device for an expressway subgrade, comprising a frame, a crushing mechanism, a rolling mechanism, a platen mechanism and a watering mechanism, the crushing mechanism, the rolling mechanism, the platen mechanism, and the watering mechanism are fixedly installed on the frame respectively, and the crushing mechanism is installed on The front end of the rolling mechanism, the rolling mechanism is installed at the front end of the pressing plate mechanism, and the sprinkler mechanism is installed above the rolling mechanism. The subgrade washed by rainwater is crushed by the crushing mechanism, and then the crushed subgrade soil is crushed by the rolling mechanism. Flattening, and finally the road surface is further leveled by the pressing plate mechanism, which is convenient to improve the efficiency of roadbed leveling, and at the same time, the dust ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap