Starting device and fire extinguishing equipment

A technology of starting device and gas device, which is applied in fire rescue and other directions, can solve the problems of mass casualties and injuries, and achieve the effects of solving the problem of pressure leakage, saving maintenance costs and expanding the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

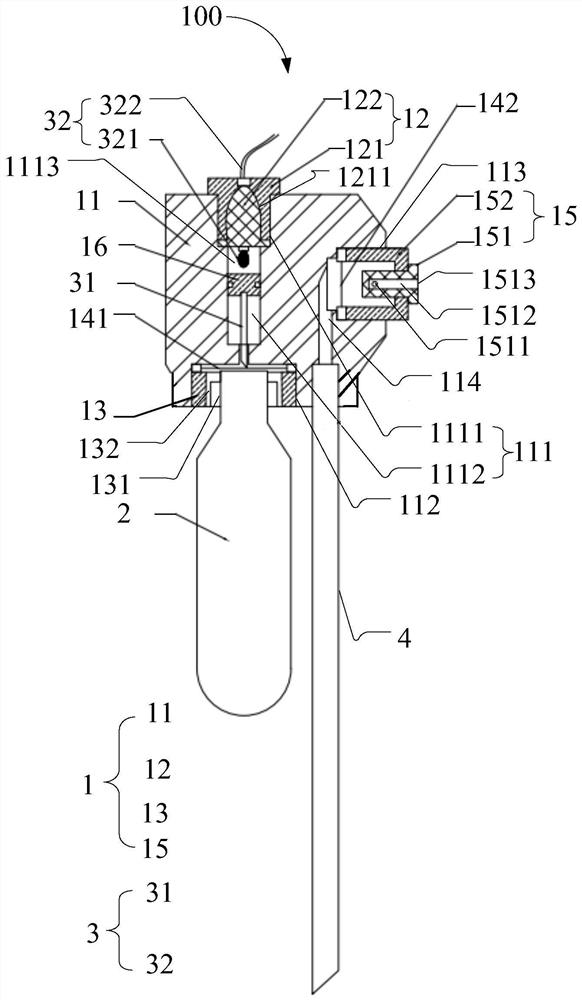

[0052] like figure 1 As shown, one embodiment of the present invention provides a starting device 100. The starting device 100 includes a housing 1, a gas supply device 2, and a trigger device 3.

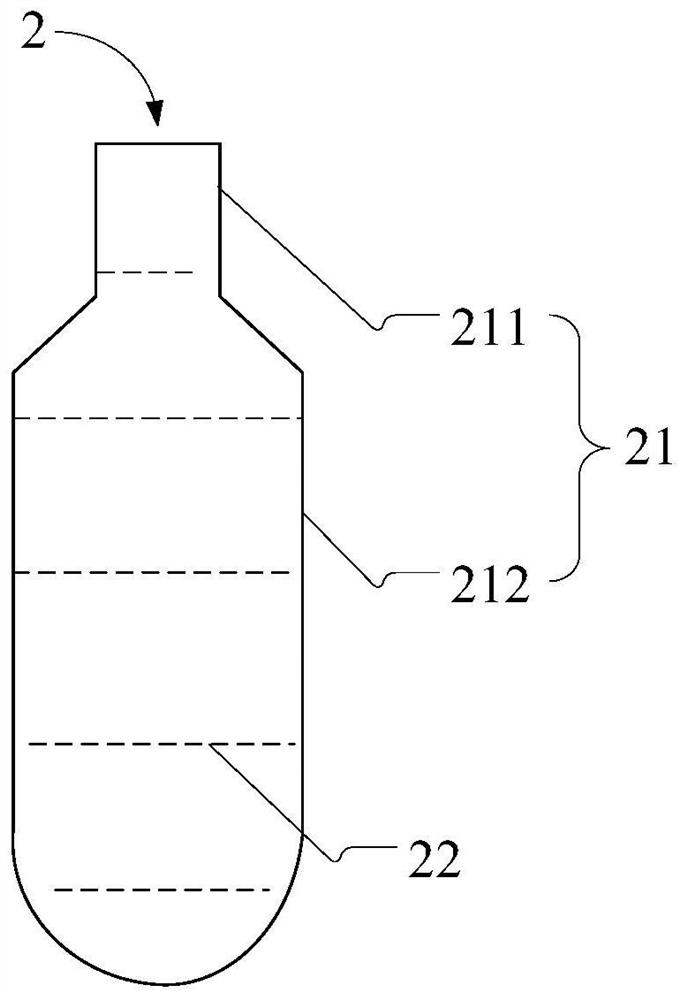

[0053] Specifically, the housing 1 is provided with at least one spout 1513, and the housing 1 is provided with a sealing chamber 1113. like figure 2 As shown, the gas supply device 2 includes an integrated sealing container 21 and a drive medium 22 in the sealing container 21. The sealing container 21 is connected to the housing 1. The initiator 3 is located outside the gas supply device 2. The initiator 3 includes a striker 31 and a trigger 32. The hit needle 31 corresponds to the sealing container 21 for puncture the sealed container 21 to cause the drive medium 22 to discharge the container 21 and form a gas. One end of the initiator 32 is within the sealing chamber 1113, and the other end of the initiator 32 extends through the housing 1 to the casing 1, and the initiator 32 is use...

Embodiment 2

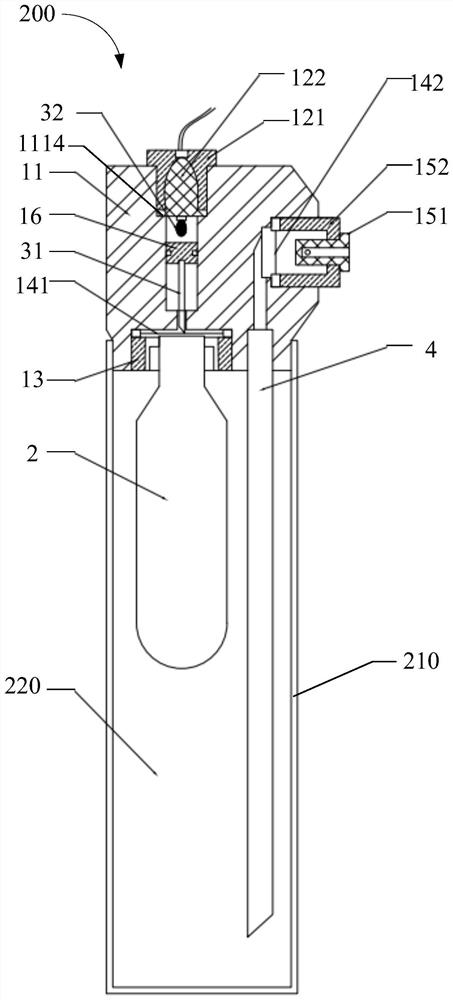

[0130] like Figure 4 Here, another embodiment of the present invention provides a starting device 100 '. The starting device 100 'includes: housing 1', gas supply device 2 ', and initiator 3'.

[0131] Specifically, the housing 1 'is provided with at least one spout 115'. The gas generating device 2 'includes an integrated sealed container 21' and a drive medium 22 'in the sealed container 21'. The sealing container 21 'is connected to the housing 1'. The initiator 3 'is located outside the gas supply device 2'.

[0132] The difference from the foregoing embodiment one is:

[0133] The initiator 3 'includes a striker 31' and a driven 32 '. The striker 31 'corresponds to the sealing container 21' for puncture the sealed container 21 'to cause the drive medium 22' to discharge the sealed container 21 'and form a gas. The initiator 32 'is mounted with the hit needle 31' for driving the striker 31 'to move in a direction near the sealing container 21' to make the collision needle 31 '...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com